Coal mill grinding roller temperature measurement system based on wireless transmission

A wireless transmission and temperature measurement technology, applied in the field of power plant equipment, can solve problems such as troublesome construction and insufficient environmental protection, and achieve the effect of reducing construction manpower, production cost, and cable consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

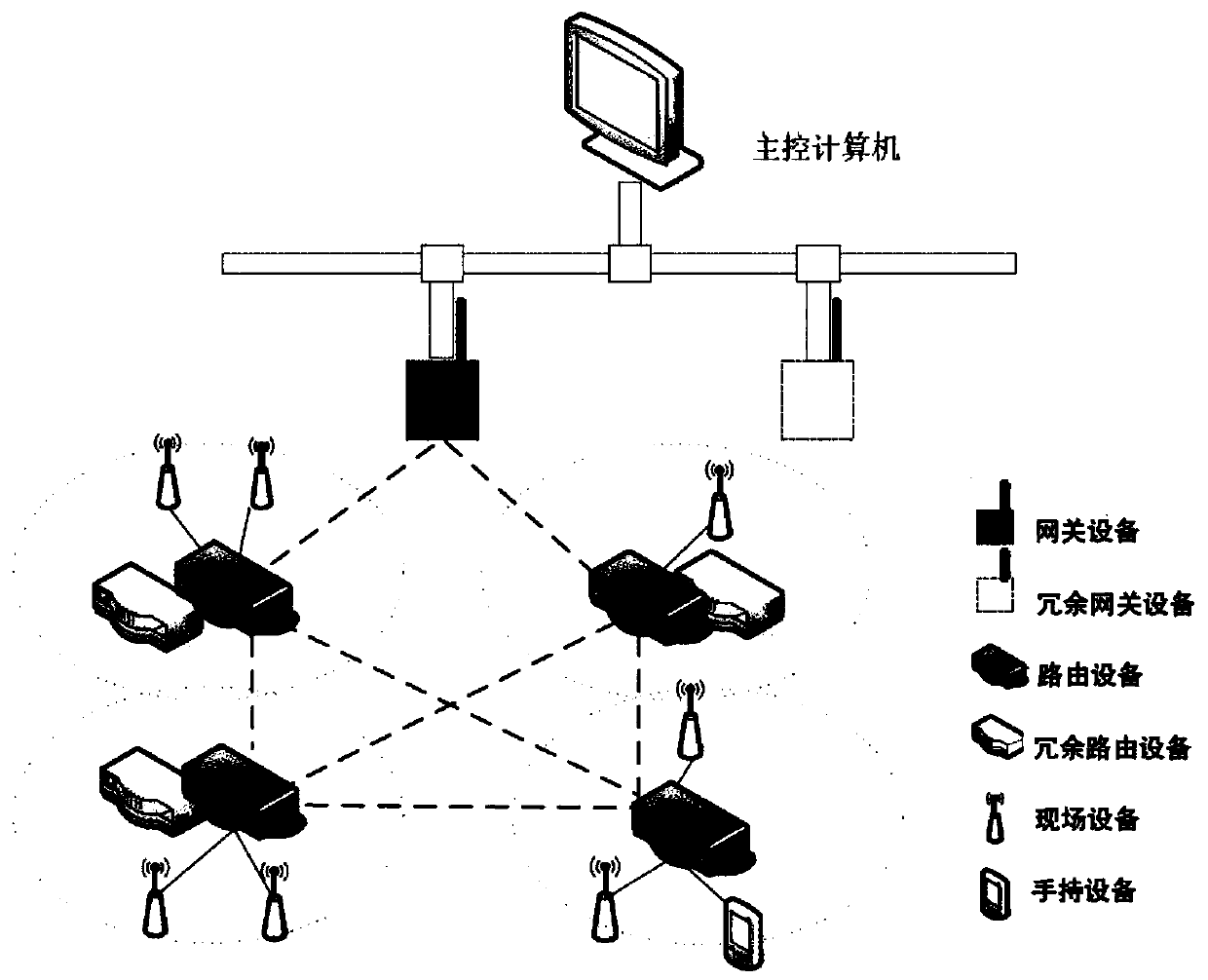

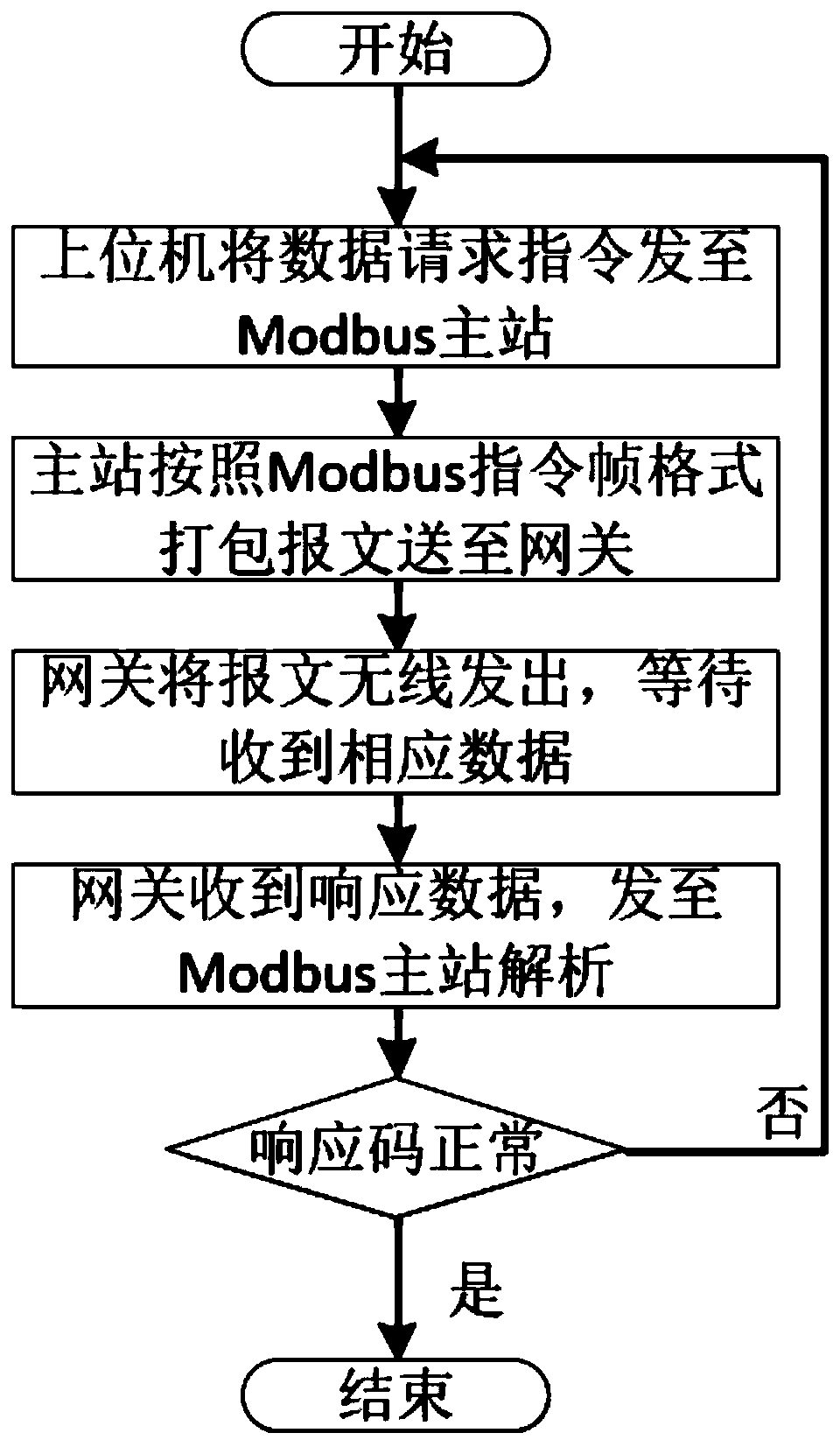

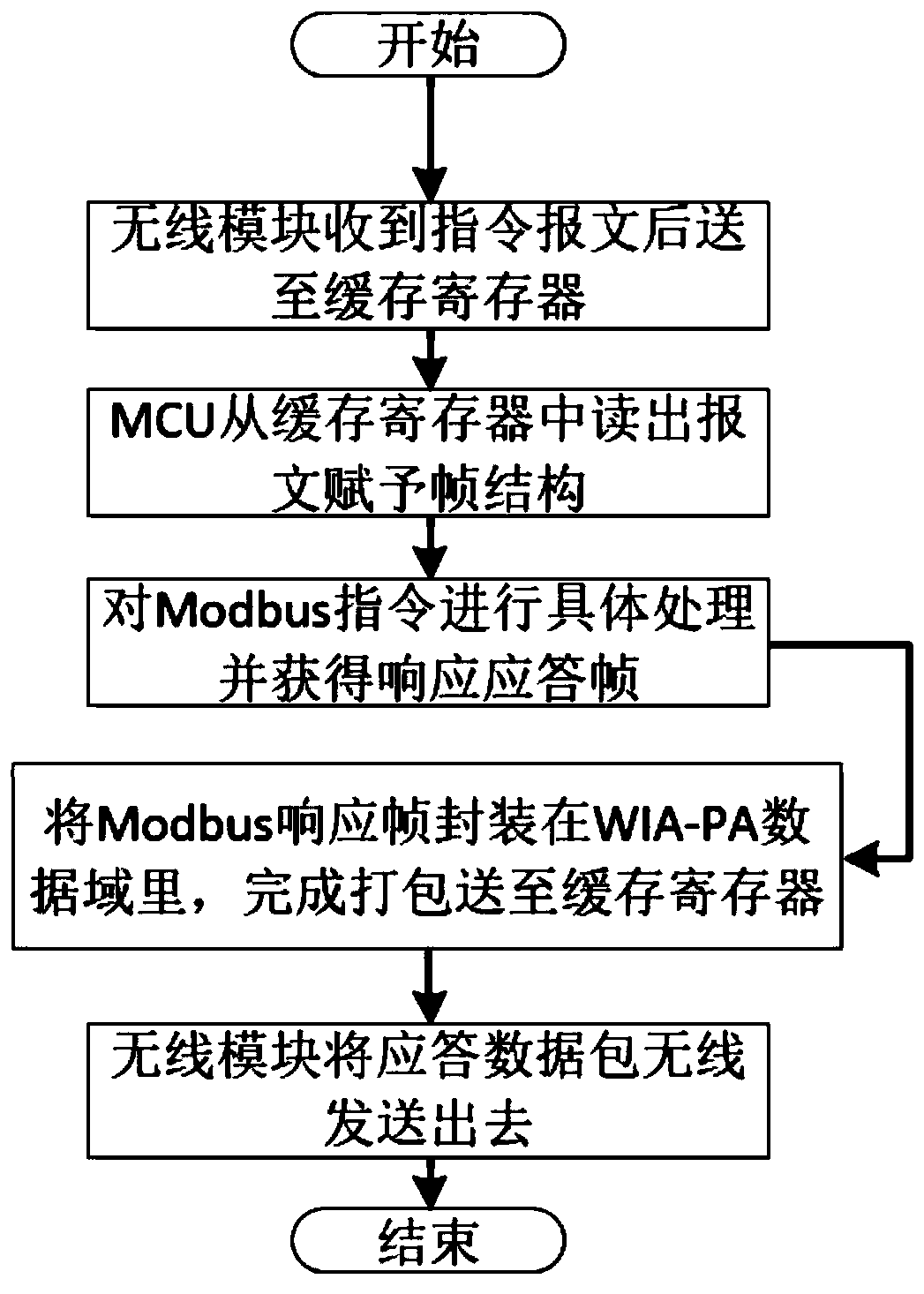

[0015] refer to Figure 1-3 , Install a wireless temperature transmitter with a WIA-PA wireless communication module at the entrance of the sealed air duct of the coal mill, install a WIA-PA intelligent wireless gateway in the local control cabinet of the coal mill, and wirelessly access three coal mills The temperature signal of the grinding roller, and monitor, manage and maintain the equipment in the WIA-PA network. The wireless gateway converts the temperature signal of the WIA-PA wireless access into the Modbus TCP protocol and transmits the data to the main control DCS through the Ethernet interface. Modbus communication card CM card, the DCS host computer can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com