Device and method for simulating diffusion and collection of tiny gas at crevasse in offline sipping of fuel assembly

A technology for simulating fuel assemblies and gas diffusion. It is used in the reduction of greenhouse gases, the measurement of radiation, and climate sustainability. It can solve problems such as the increase in internal and external pressure differences, and achieve high reduction degree, high safety and economy. Design small-scale effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in detail:

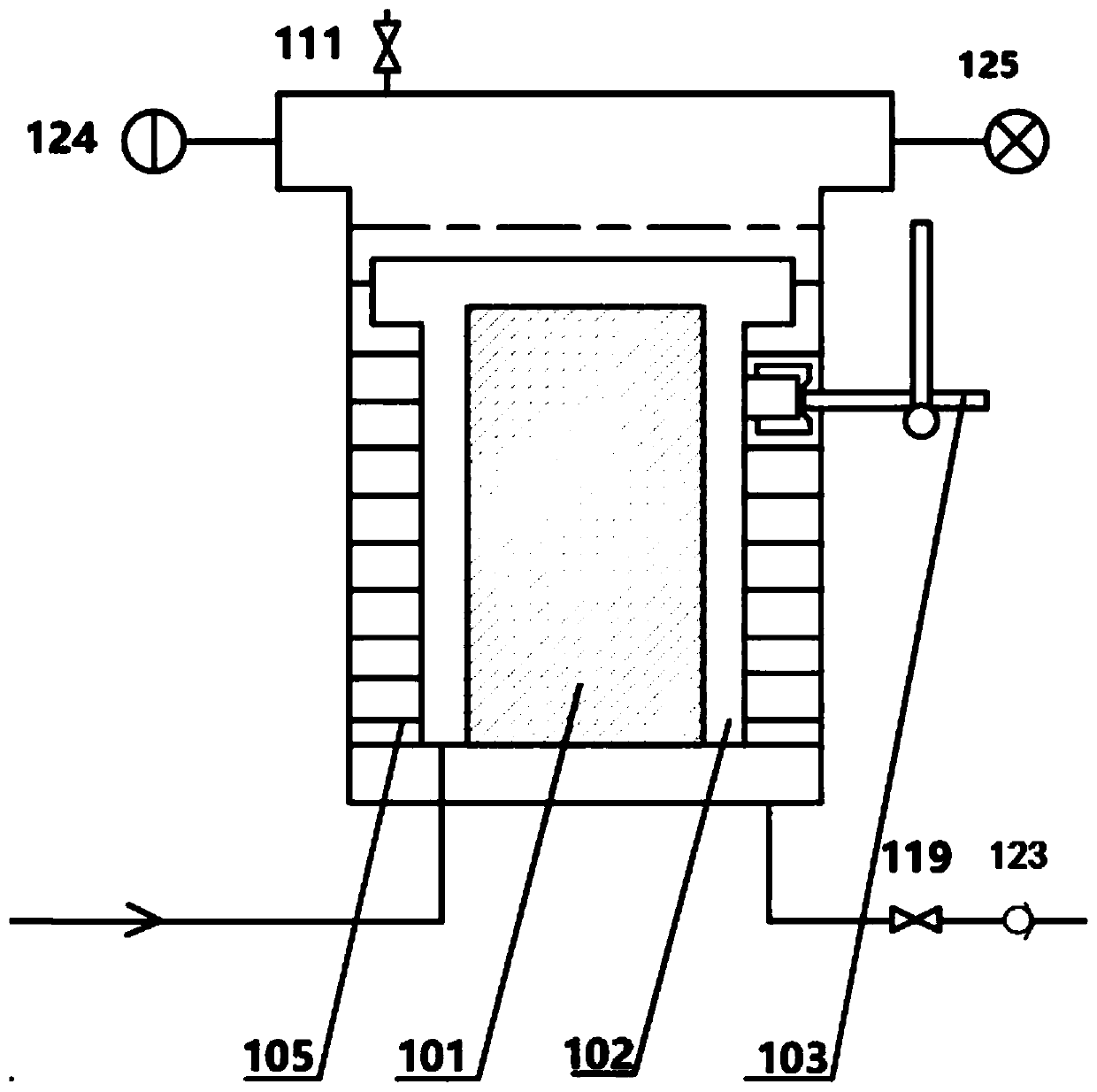

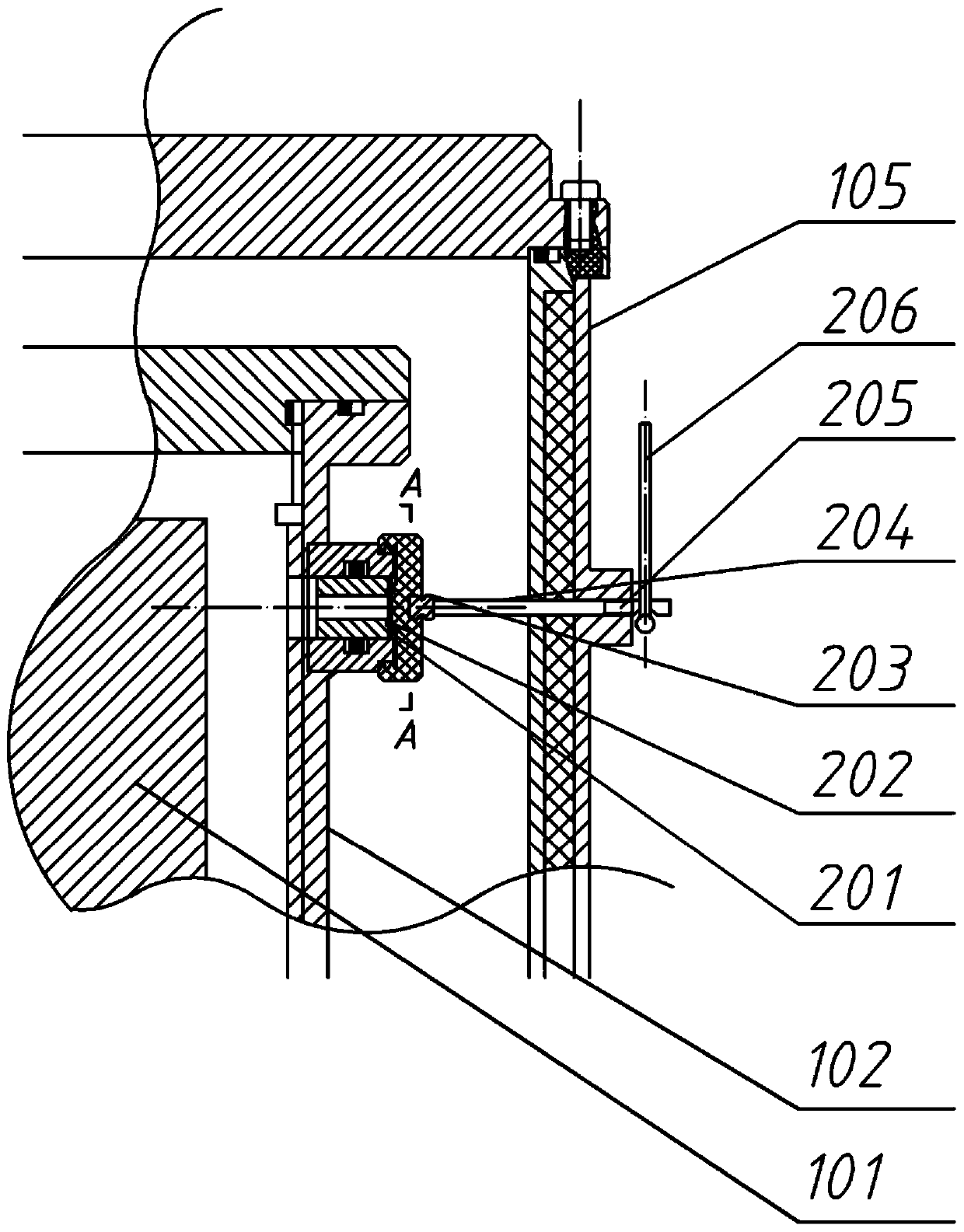

[0017] like figure 1 As shown, the present invention is a device for simulating the diffusion and collection of tiny gas at the break in the off-line sipping of fuel assemblies, including a rod core 101, an inner cylinder 102 and an outer cylinder 105, wherein the rod core 101 is used for simulating fuel element pellets, and the rod The core 101 is placed in the inner cylinder 102, and the inner cylinder 102 is used to simulate the gas space containing fission gas inside the fuel element; the side of the inner cylinder 102 is provided with a breach opening and closing device 103, which is used to simulate the breach of the fuel element; The bottom of 102 is connected to the multi-purpose gas system; the outer cylinder 105 simulating the water circuit, and the inner cylinder 102 for simulating fuel elements are placed inside, and the outer cylinder 105 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com