Method and device for preparing high-entropy alloy coating through alternating-current and direct-current composite magnetic field with assistance of laser cladding

A composite magnetic field and auxiliary laser technology, which is applied in the field of high-entropy alloy coating preparation, can solve problems such as uneven distribution of structure, and achieve the effects of improving composition segregation, uniform distribution of structure, and compensating for poor homogenization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

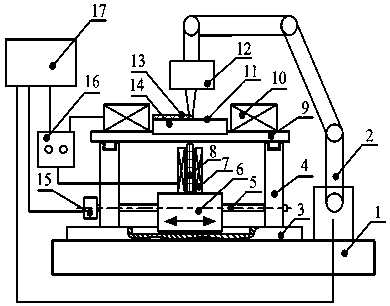

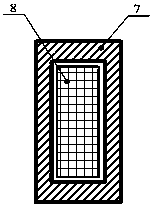

[0028] In this example, see figure 1 , a method for AC / DC composite magnetic field assisted laser cladding high entropy alloy coating, it comprises the following steps:

[0029]A. Grind the 40mm*40mm*6mm IN718 nickel-based superalloy with 800# sandpaper, clean and dry it with alcohol, and place it on the upper support plate with a fixture; mill the AlCoCrFeNiHf high-entropy alloy powder in a ball mill for 3 Hours, the ball-milled high-entropy alloy powder is screened out by a powder sieving machine with a particle size ranging from 200 to 300 mesh as powder for laser cladding;

[0030] B. Control the AC and DC power supply through the controller, turn on the DC power supply module to supply power to the excitation coil II, the supply current is 20A, and generate a 100mT horizontal stable DC magnetic field;

[0031] C. Synchronously turn on the AC power supply module to supply power to the rectangular excitation coil Ⅰ, the AC current is 10A, and a longitudinal AC magnetic fie...

Embodiment 2

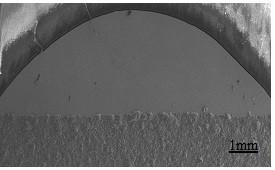

[0038] The cross-sectional morphology and microstructure of the AlCoCrFeNiHf high-entropy alloy coating obtained in this example are as follows: image 3 and 4 It can be seen that there are no defects such as pores and cracks at the junction of the coating and the substrate, and good metallurgical bonding has been achieved. At the same time, the microstructure has formed a fine equiaxed crystal structure, and the distribution of the structure is more uniform. The micro-segregation degree of each alloying element decreased by more than 30% compared with the high-entropy alloy coating without composite magnetic field assistance, and the segregation ratio was closer to 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com