Preparation method of graphene oxide/acrylate-epoxy resin composite anticorrosive paint

An epoxy resin and acrylate technology, applied in anti-corrosion coatings, coatings, etc., can solve problems such as high equipment requirements, complex processes, and limited graphene development, and achieve great application prospects, improve anti-corrosion performance, and excellent metal anti-corrosion. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

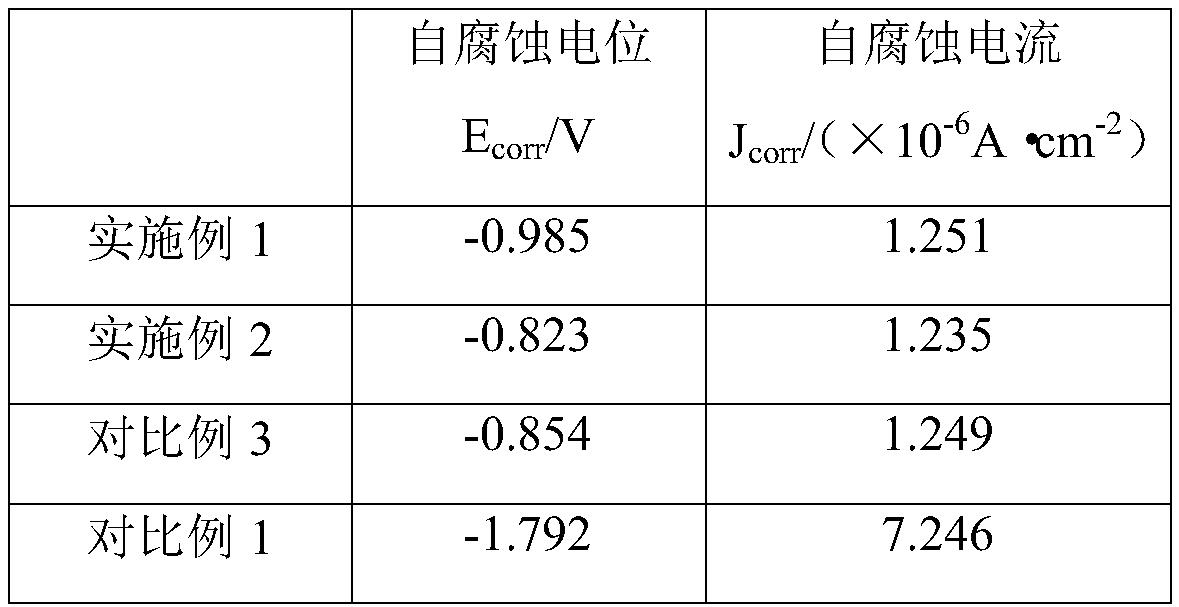

Examples

Embodiment 1

[0026] A preparation method for graphene oxide / acrylate-epoxy resin composite anticorrosion coating, comprising the following steps:

[0027] Step 1: Take 40g of graphene and 20g of sodium nitrate in a 500mL three-neck flask in an ice-water bath at 0°C, then add 80mL of concentrated sulfuric acid and stir for 30min until evenly mixed, then gradually add 120g of potassium permanganate, dropwise for 90min , after the dropwise addition, the reaction vessel was transferred to a constant temperature water bath at 40°C, and 90mL of deionized water was slowly added dropwise to react for 1 hour. After the reaction was completed, 6mL of 30% hydrogen peroxide aqueous solution was added until the reaction solution became Bright yellow, then placed in a centrifuge tube, centrifuged at a speed of 5000r / min until the pH of the supernatant is neutral, the colloid in the lower layer is taken out, and dried in a vacuum oven at 35°C for 72 hours to obtain graphene oxide;

[0028] Step 2: Take b...

Embodiment 2

[0034] A preparation method for graphene oxide / acrylate-epoxy resin composite anticorrosion coating, comprising the following steps:

[0035] Step 1: Take 60g of graphene and 30g of sodium nitrate in a 500mL three-neck flask in an ice-water bath at 0°C, then add 80mL of concentrated sulfuric acid and stir for 30min until the mixture is uniform, then gradually add 180g of potassium permanganate, dropwise for 90min , after the dropwise addition, the reaction vessel was transferred to a constant temperature water bath at 40°C, and 90mL of deionized water was slowly added dropwise to react for 1 hour. After the reaction was completed, 6mL of 30% hydrogen peroxide aqueous solution was added until the reaction solution became Bright yellow, then placed in a centrifuge tube, centrifuged at a speed of 5000r / min until the pH of the supernatant is neutral, the colloid in the lower layer is taken out, and dried in a vacuum oven at 35°C for 72 hours to obtain graphene oxide;

[0036] Step...

Embodiment 3

[0042] A preparation method for graphene oxide / acrylate-epoxy resin composite anticorrosion coating, comprising the following steps:

[0043] Step 1: Take 20g of graphene and 10g of sodium nitrate in a 500mL three-neck flask in an ice-water bath at 0°C, then add 80mL of concentrated sulfuric acid and stir for 30min until the mixture is uniform, then gradually add 60g of potassium permanganate, dropwise for 90min , after the dropwise addition, the reaction vessel was transferred to a constant temperature water bath at 40°C, and 90mL of deionized water was slowly added dropwise to react for 1 hour. After the reaction was completed, 6mL of 30% hydrogen peroxide aqueous solution was added until the reaction solution became Bright yellow, then placed in a centrifuge tube, centrifuged at a speed of 5000r / min until the pH of the supernatant is neutral, the colloid in the lower layer is taken out, and dried in a vacuum oven at 35°C for 72 hours to obtain graphene oxide;

[0044] Step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com