Self-repairing polyester based on multiple hydrogen bonds as well as preparation method and application thereof

A multiple hydrogen bond and self-repairing technology is applied in the preparation of self-repairing polyester and in the field of polyester preparation, which can solve the problems of difficult mechanical strength and self-repairing cycle of polyurethane, and achieves novel preparation method, strong practicability, and high production efficiency. simple method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

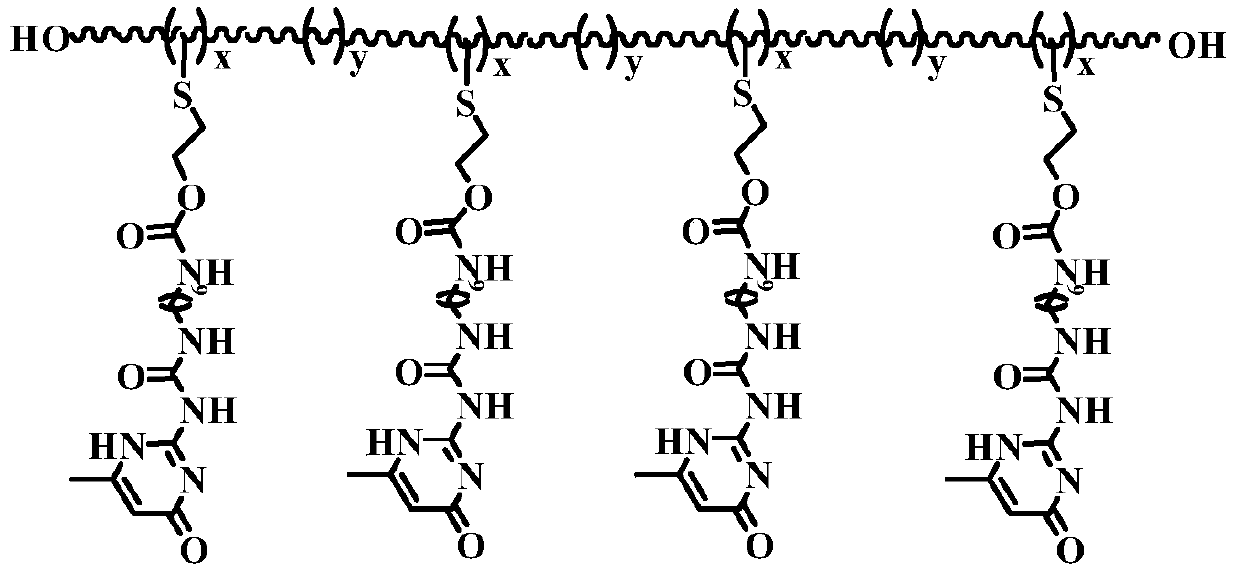

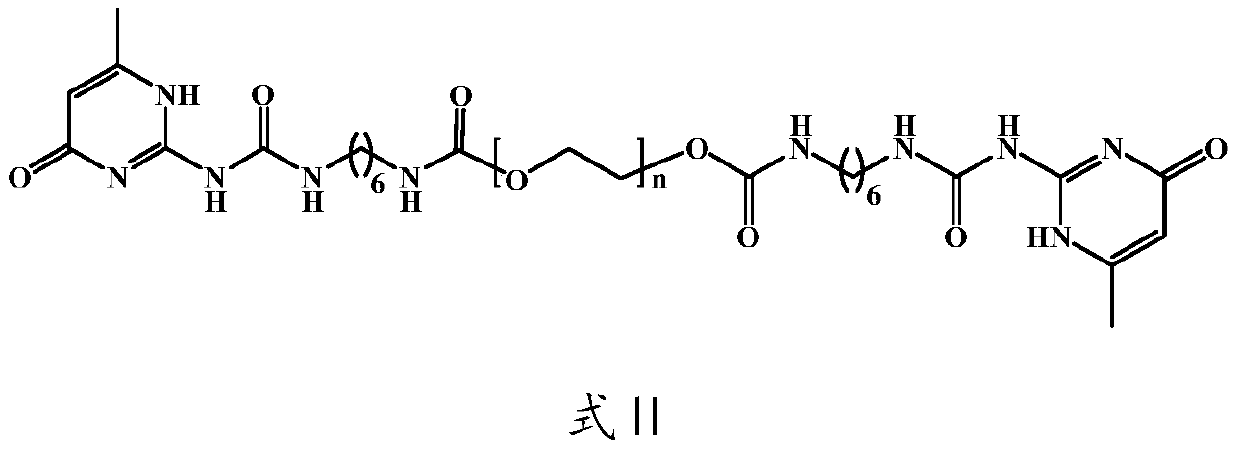

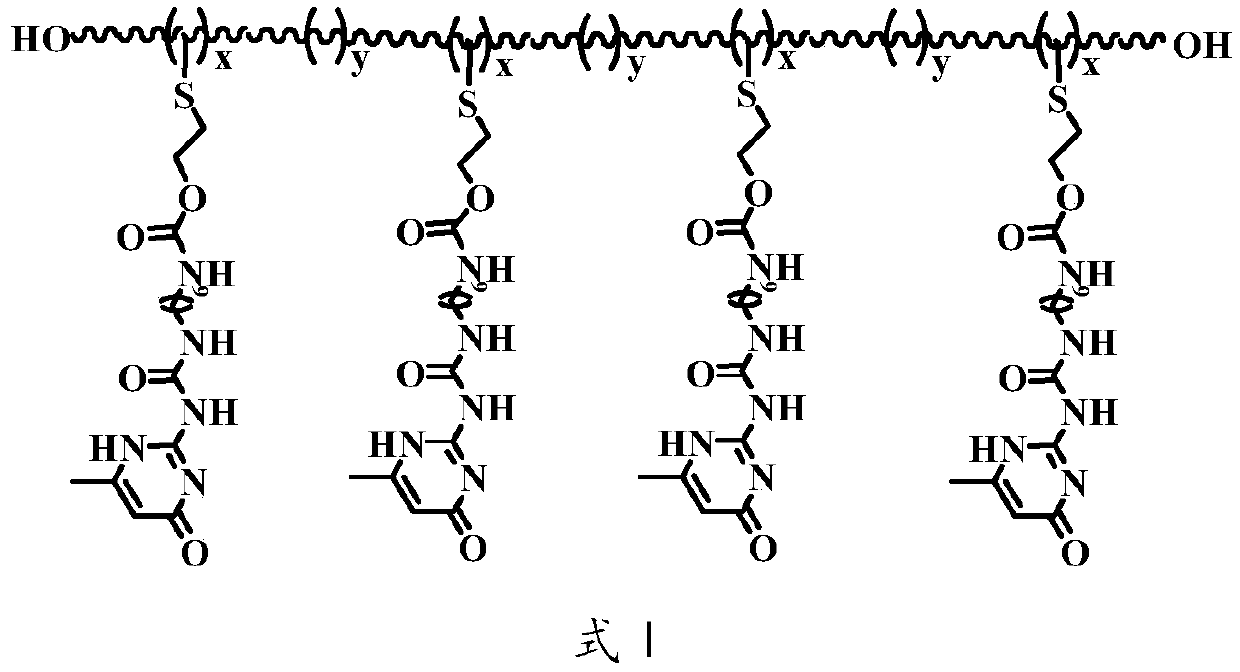

[0032] The present invention also provides a preparation method of polyester with self-repair function, comprising:

[0033] Poly(butylene itaconate-co-butylene succinate) (PBIS) and UPy-NCO supramolecular polymer were used as raw materials, and 2-mercaptoethanol was used as chain extender through mercapto-ene click reaction. UPy was grafted into PBIS to obtain an unsaturated polyester (PBIS-U) containing UPy in side groups. At the same time, the UPy-NCO supramolecular polymer was grafted onto the terminal hydroxyl groups of polyethylene glycol (PEG-2000) to obtain UPy-terminated polyethylene glycol (PEG-U). After the reaction is complete, the unsaturated polyester (PBIS-U) containing UPy in the side group (PBIS-U) and the polyethylene glycol (PEG-U) blocked by UPy are mixed, and UPy (2-urea-4[H]-pyrimidinone) is used to The system can form dimerization and cross-link through the action of quadruple hydrogen bond to obtain cross-linked polyester.

[0034] The self-healing pe...

Embodiment 1

[0049] Weigh 10g of poly(butylene itaconate-co-butylene succinate) (PBIS) and dissolve it in a three-necked flask filled with 50mL of chloroform, then slowly add 2-mercaptoethanol dropwise while stirring, the amount It is 80% of the double bond content in PBIS, and a photoinitiator DMPA (benzoin dimethyl ether) is added in an amount of 0.15% of the PBIS mass. Then, it was stirred under a nitrogen atmosphere for 30 min and irradiated with a UV lamp for 1 h at room temperature, at which time 2-mercaptoethanol was grafted into PBIS via a mercapto-ene click reaction. Then, add UPy-NCO into the flask, the addition amount is 80% of the double bond content in PBIS, use chloroform solution as solvent, connect spherical condenser, thermometer and stirrer, raise the temperature to 80°C under nitrogen protection and stir. After 4 hours, an unsaturated polyester (PBIS-U) containing UPy in side groups was obtained.

[0050] Put polyethylene glycol and UPy-NCO with a molar ratio of 1:2 in ...

Embodiment 2

[0053] Weigh 10g of poly(butylene itaconate-co-butylene succinate) (PBIS) and dissolve it in a three-necked flask filled with 50mL of chloroform, then slowly add 2-mercaptoethanol dropwise while stirring, the amount It is 20% of the double bond content in PBIS, and the photoinitiator DMPA is added in an amount of 0.15% of the mass of PBIS. Then, it was stirred under a nitrogen atmosphere for 30 min and irradiated with a UV lamp for 1 h at room temperature, at which time 2-mercaptoethanol was grafted into PBIS via a mercapto-ene click reaction. Then, add UPy-NCO into the flask, the addition amount is 20% of the double bond content in PBIS, use chloroform solution as solvent, connect spherical condenser, thermometer and stirrer, raise the temperature to 80°C under nitrogen protection and stir. After 4 hours, an unsaturated polyester (PBIS-U) containing UPy in side groups was obtained.

[0054] Put polyethylene glycol and UPy-NCO with a molar ratio of 1:2 in a 100ml four-necked ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com