A new cathodic and anode electrocatalytic synergistic flue gas denitrification method

An electrocatalysis, cathode and anode technology, applied in the field of new cathode and anode electrocatalysis synergistic flue gas denitrification, can solve the problems of large consumption of reagents, increase of waste liquid follow-up treatment, restrictions, etc., and achieve no secondary pollution, low cost, and out-of-stock efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

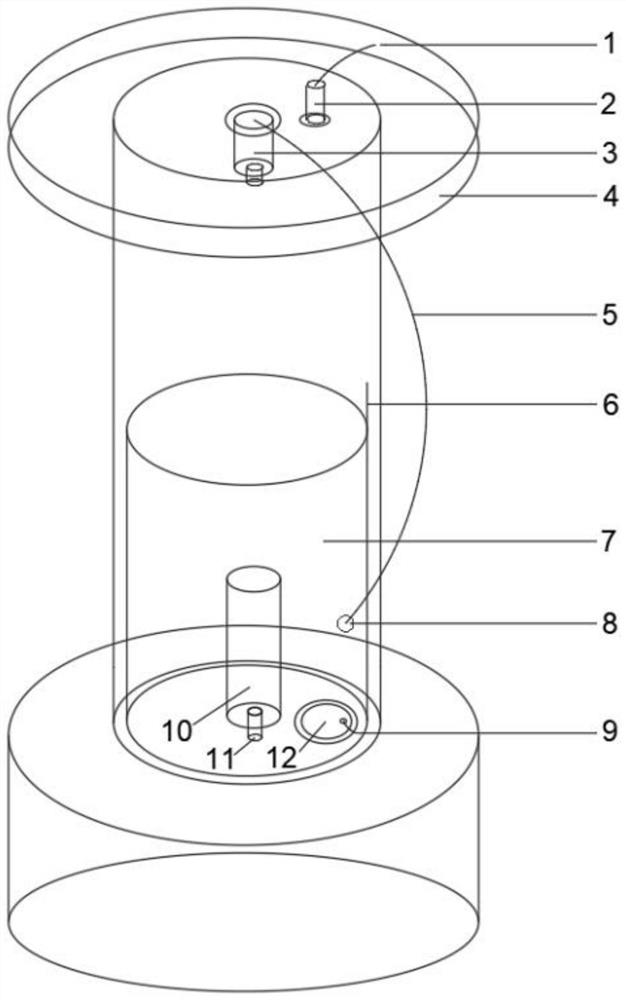

Embodiment 1

[0026] Using Ti / IrO 2 -RuO 2 is the anode, copper is the cathode, and the distance between the electrodes is 5 cm. Using 0.05M NaCl as the electrolyte, the initial pH value was adjusted to 7. The concentration of NO is 500ppm, and it enters the solution through a membrane microporous aerator at a flow rate of 1L / min. The electrolyte is sprayed from the top spray device through the lift pump, and part of the gas that overflows the solution is brought back to the solution. After the treated gas overflows from the top of the reactor, it is introduced into a gas cylinder, and its concentration is measured by a flue gas analyzer to monitor the degree of NOx treatment in real time.

[0027] Working current density is 20mA / cm 2 , the NO conversion rate was 90%.

Embodiment 2

[0029] The lead oxide electrode is used as the anode, and the metal Pd coating is used as the cathode, and the distance between the electrodes is 5 cm. Using 0.07M NaCl as the electrolyte, the initial pH value was adjusted to 7. The concentration of NO is 500ppm, and it enters the solution through the membrane microporous aerator at a flow rate of 1.2L / min. The electrolyte is sprayed from the top spray device through the lift pump, and part of the gas that overflows the solution is brought back to the solution. After the treated gas overflows from the top of the reactor, it is introduced into a gas cylinder, and its concentration is measured by a flue gas analyzer to monitor the degree of NOx treatment in real time.

[0030] Working current density is 25mA / cm 2 , the NO conversion rate was 92%.

Embodiment 3

[0032] Using Sb-SnO 2 The electrode is the anode, the metal cobalt is the cathode, and the distance between the electrodes is 6cm. Using 0.08M NaCl as the electrolyte, the initial pH value was adjusted to 7. The concentration of NO is 500ppm, and it enters the solution through the membrane microporous aerator at a flow rate of 1.3L / min. No spraying device is used, the treated gas overflows from the top of the reactor and is introduced into a gas cylinder, and the concentration is measured by a flue gas analyzer to monitor the degree of NOx treatment in real time.

[0033] The working current density is 30mA / cm 2 , the NO conversion rate was 80%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com