A kind of modified urea denitration agent and preparation method thereof

A technology of modified urea and denitrification agent, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, etc. It can solve problems such as the reduction of SNCR denitrification efficiency, the oxidation of ammonia or urea, and the reduction of NOx reduction activity by ammonia or urea. Effect of widening the working temperature, increasing reactivity, and improving reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] 1) Preparation of modified urea denitrification agent:

[0017] Step 1: prepare synergist: under room temperature condition, the sodium cocoyl glycinate of 1.5 parts by mass and the sodium lauryl sulfate of 0.5 part are dissolved in the water of 100.0 parts by mass, add the aqueous phosphoric acid solution of 1.0 parts by mass ( Mass percent concentration is 20.0%), stir evenly. Thereafter, 8.0 parts by mass of ethyl orthosilicate was added. After continuing to stir for 20 minutes, the product was filtered out and dried at 50°C to obtain phosphorylated silica vesicles. Add 100.0 parts by mass of phosphorylated silica vesicles to 1000 parts by mass of an aqueous solution of titanyl sulfate (wherein: the mass percent concentration is 15.0%) and stir for 20 minutes, then filter and dry at 50 degrees Celsius. The synergistic component A is obtained. The element content of titanium metal element is: 2.3%.

[0018] Step 2: 100.0 parts by mass of urea, 0.5 parts by mass of...

Embodiment 2

[0026] 1) Preparation of modified urea denitrification agent:

[0027] Step 1: prepare synergist: under room temperature condition, the sodium cocoyl glycinate of 1.5 mass parts and the sodium lauryl sulfate of 0.6 part are dissolved in the water of 100.0 mass parts, add the phosphoric acid aqueous solution of 1.9 mass parts ( Mass percent concentration is 20.0%), stir evenly. Thereafter, 12.0 parts by mass of ethyl orthosilicate was added. After continuing to stir for 20 minutes, the product was filtered out and dried at 50°C to obtain phosphorylated silica vesicles. 100 mass parts of phosphorylated silicon dioxide vesicles are added to an aqueous solution of metal salts (wherein: the mass percentage concentration of titanyl sulfate is 1.0%; the mass percentage concentration of zinc sulfate is 13.0%; the mass percentage concentration of manganese sulfate is 1000 mass parts) After stirring for 20 minutes in a concentration of 1.0% by mass, it was filtered and dried at 50 deg...

Embodiment 3

[0031] 1) Preparation of modified urea denitrification agent:

[0032] Step 1: prepare synergist: under room temperature condition, the sodium cocoyl glycinate of 1.0 mass parts and the sodium lauryl sulfate of 0.8 parts are dissolved in the water of 100.0 mass parts, add the phosphoric acid aqueous solution of 1.5 mass parts ( Mass percent concentration is 20.0%), stir evenly. Thereafter, 10.0 parts by mass of ethyl orthosilicate was added. After continuing to stir for 20 minutes, the product was filtered out and dried at 50°C to obtain phosphorylated silica vesicles. Add 100 parts by mass of phosphorylated silica vesicles to 1000 parts by mass of an aqueous solution of a metal salt (wherein: the mass percentage concentration of titanyl sulfate is 2.2%; the mass percentage concentration of manganese sulfate is 12.8%) and stir for 20 Minutes later, filter and dry at 50°C to obtain synergistic component C. The content of titanium element is: 0.5%; the content of manganese el...

PUM

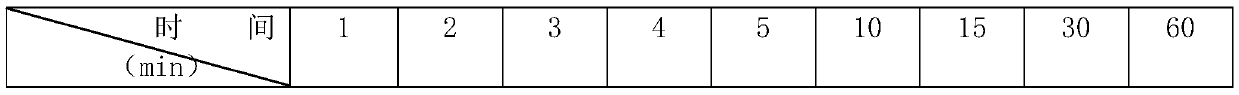

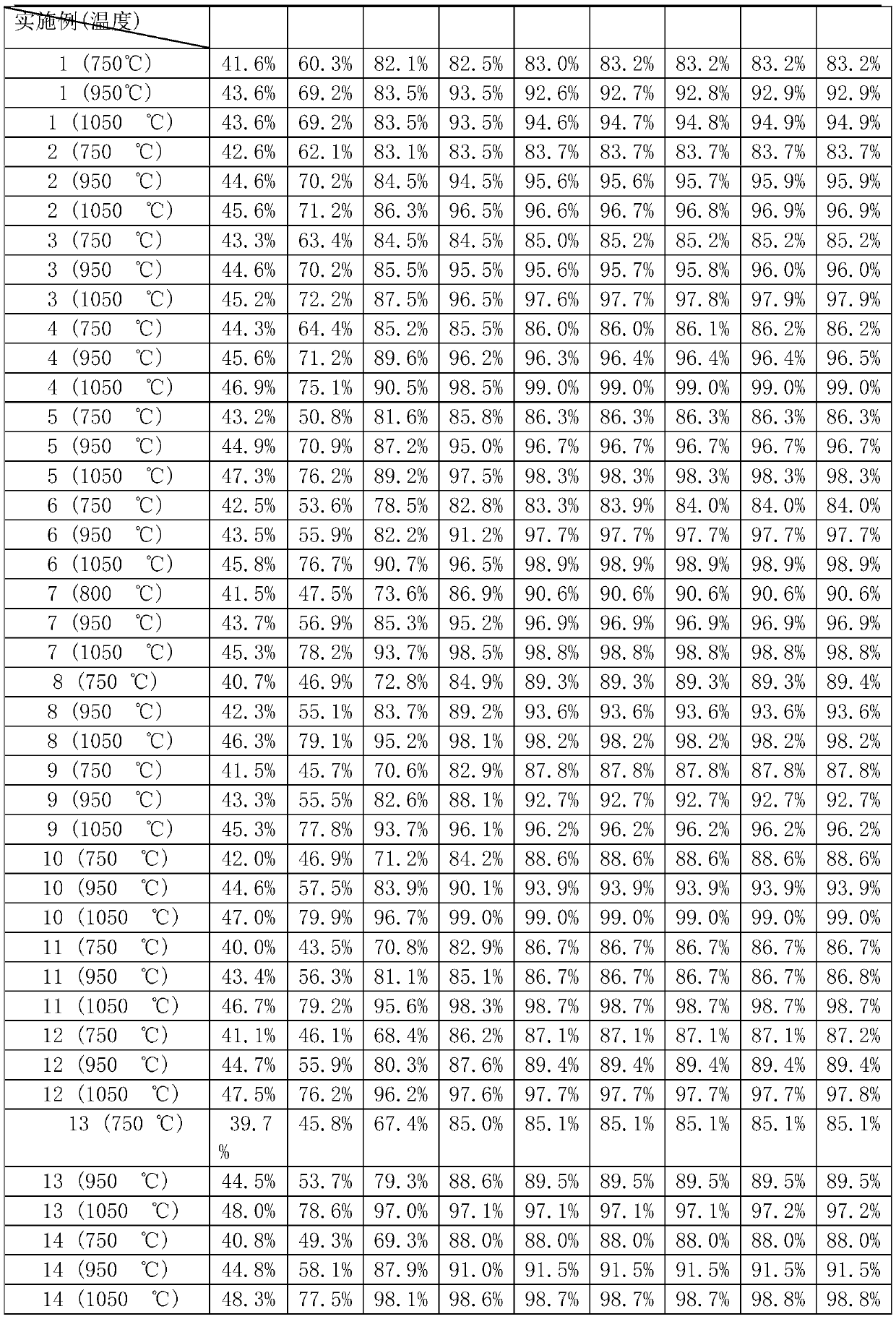

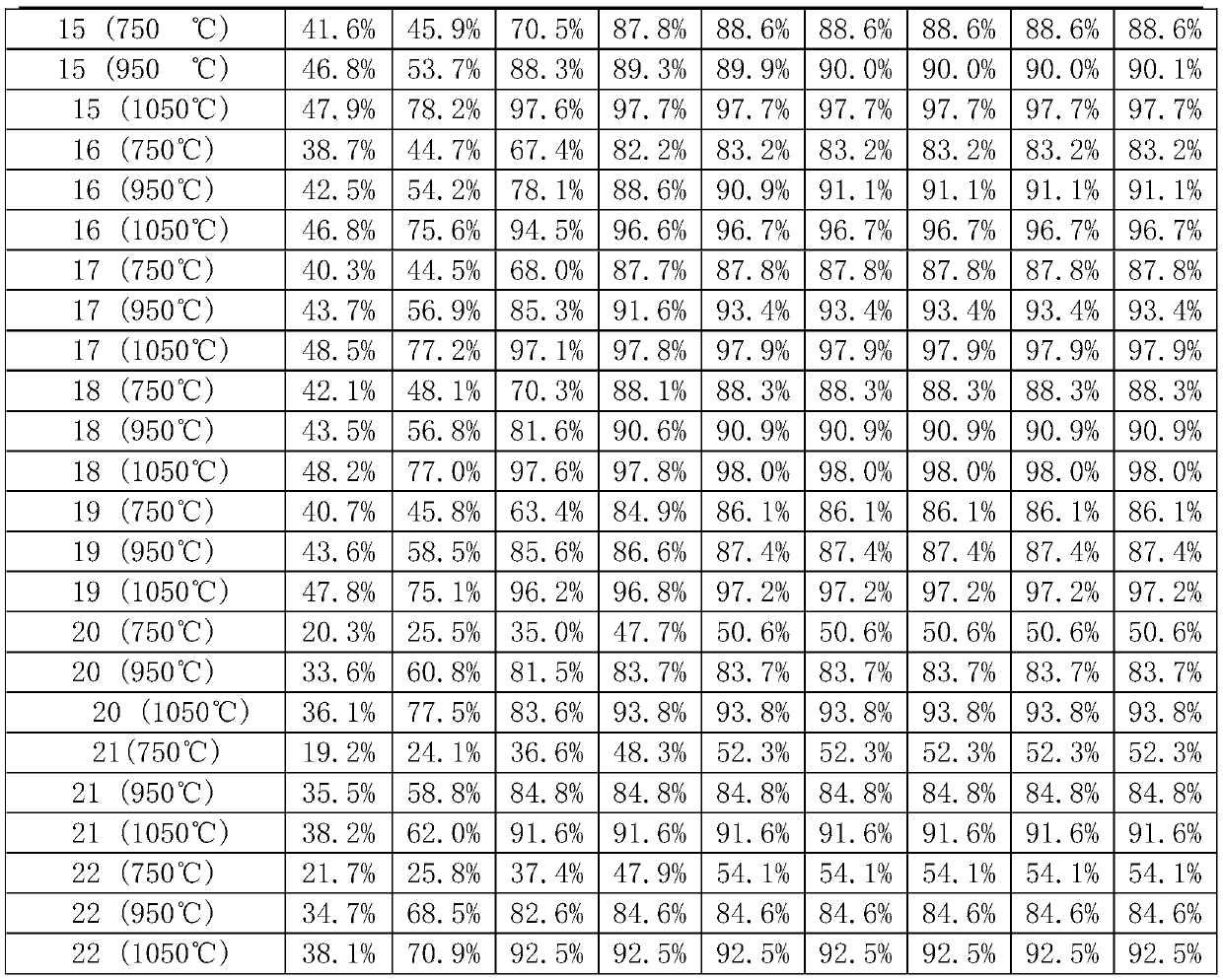

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com