A Method for Predicting the Cycle Life of Lithium-ion Batteries Based on Acoustic Measurements

A lithium-ion battery, cycle life technology, applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., can solve the prediction time, parameter measurement, model adaptive convergence speed, insufficient prediction accuracy, difficult to determine the penalty factor and loss function , long training time and other problems, to achieve the effect of shortening the time required for prediction, good application prospects, and fast scanning speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

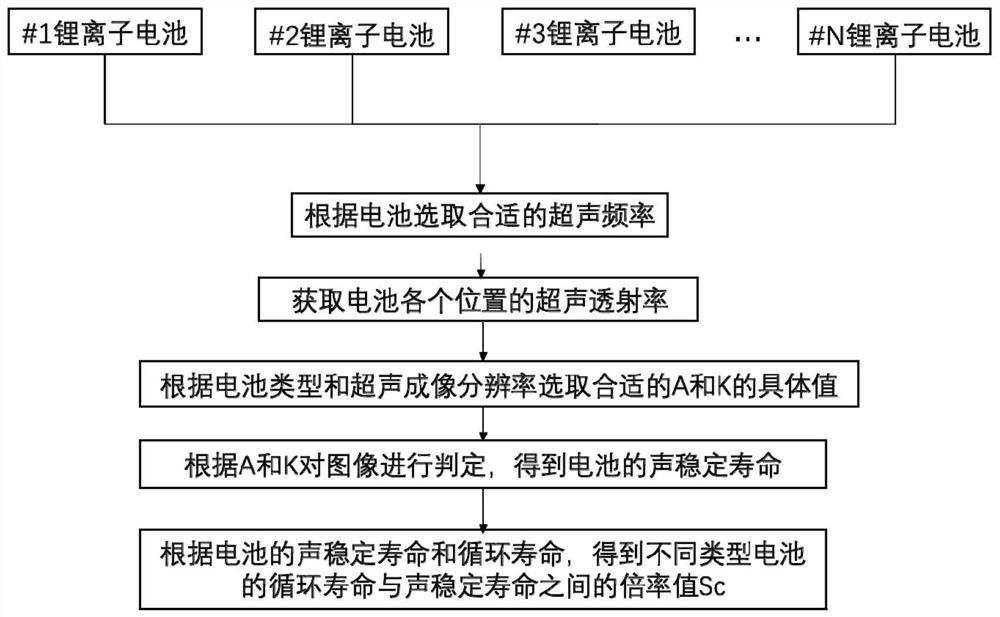

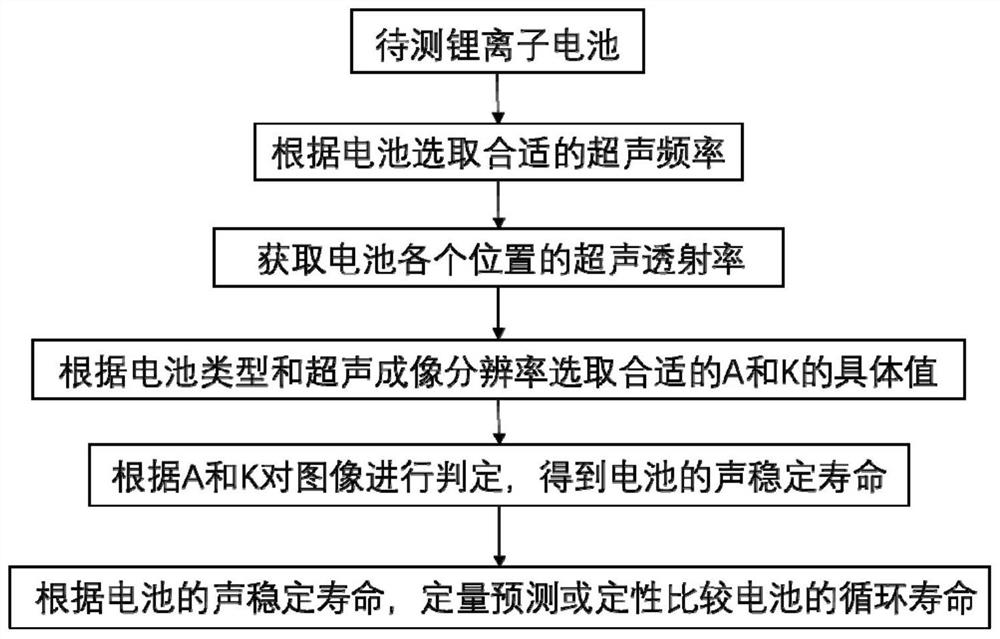

Method used

Image

Examples

Embodiment 1

[0030] In this embodiment, an NCM622 ternary lithium-ion battery is taken as an example. Its nominal capacity is 5Ah, the normal charge and discharge range is 2.8-4.2V, and the working temperature range is 5-45°C. The specific prediction method includes the following steps:

[0031] (1) Put the lithium-ion battery in a constant temperature and humidity box of the Dongguan Bell BHT-150C model, set the temperature to 25°C, and wait for the temperature in the constant temperature and humidity box to reach the set value;

[0032] (2) Use Xinwei BTS-8000 charging and discharging equipment to charge and discharge the lithium-ion battery. The specific steps of the charging and discharging cycle are: charge at 1C, and when the terminal voltage of the lithium-ion battery reaches 4.2V, change to Charge at constant voltage until the charging current is less than or equal to 0.05C, stop charging, put it aside for 0.5h, then discharge to 2.8V with a current of 1C, after the discharge is com...

Embodiment 2

[0037] In this embodiment, an NCM622 ternary lithium-ion battery is taken as an example. Its nominal capacity is 8.7Ah, the normal charge and discharge range is 2.8-4.2V, and the working temperature range is 5-45°C. The specific prediction method includes the following steps:

[0038] (1) Put the lithium-ion battery in a constant temperature and humidity box of the Dongguan Bell BHT-150C model, set the temperature to 20°C, and wait for the temperature in the constant temperature and humidity box to reach the set value;

[0039] (2) Use Xinwei BTS-8000 charging and discharging equipment to charge and discharge the lithium-ion battery. The specific steps of the charging and discharging cycle are: charge at 1C, and when the terminal voltage of the lithium-ion battery reaches 4.2V, change to Constant voltage charging until the charging current is less than or equal to 0.05C, stop charging, put it aside for 0.8h, then discharge to 2.8V with a current of 1C, after the discharge, put ...

Embodiment 3

[0044] In this embodiment, a lithium-ion battery made of NCM523 ternary material is taken as an example. Its nominal capacity is 20Ah, its normal charge and discharge range is 2.8-4.2V, and its operating temperature range is 5°C to 45°C. The specific prediction method includes the following steps:

[0045] (1) Put the lithium-ion battery in a constant temperature and humidity box of the Dongguan Bell BHT-150C model, set the temperature to 30°C, and wait for the temperature in the constant temperature and humidity box to reach the set value;

[0046] (2) Use Xinwei BTS-8000 charging and discharging equipment to charge and discharge the lithium-ion battery. The specific steps of the charging and discharging cycle are: charge at 1C, and when the terminal voltage of the lithium-ion battery reaches 4.2V, change to Charge at constant voltage until the charging current is less than or equal to 0.05C, stop charging, put it aside for 0.9h, then discharge to 2.8V with a current of 1C, af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com