On-arch secondary air and gap type exhaust steam staggered W flame boiler and air distribution method

A slit type, secondary air technology, applied in the air distribution of W flame boilers and coal-fired power plant boilers, can solve the problems of late ignition of pulverized coal airflow, unstable combustion, high NOx emissions, etc., to extend the burnout distance, Effect of preventing slagging and reducing NOx emission level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

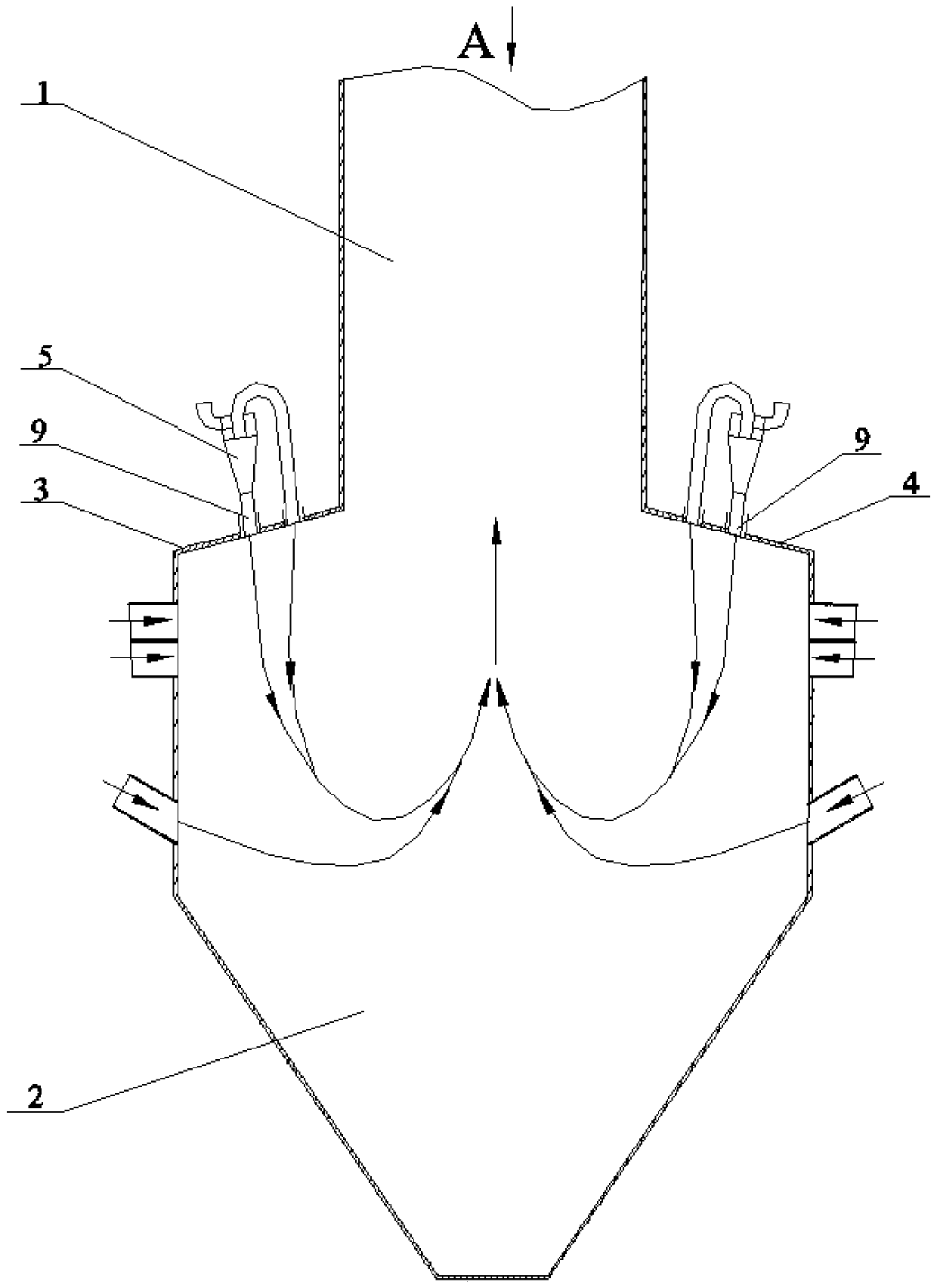

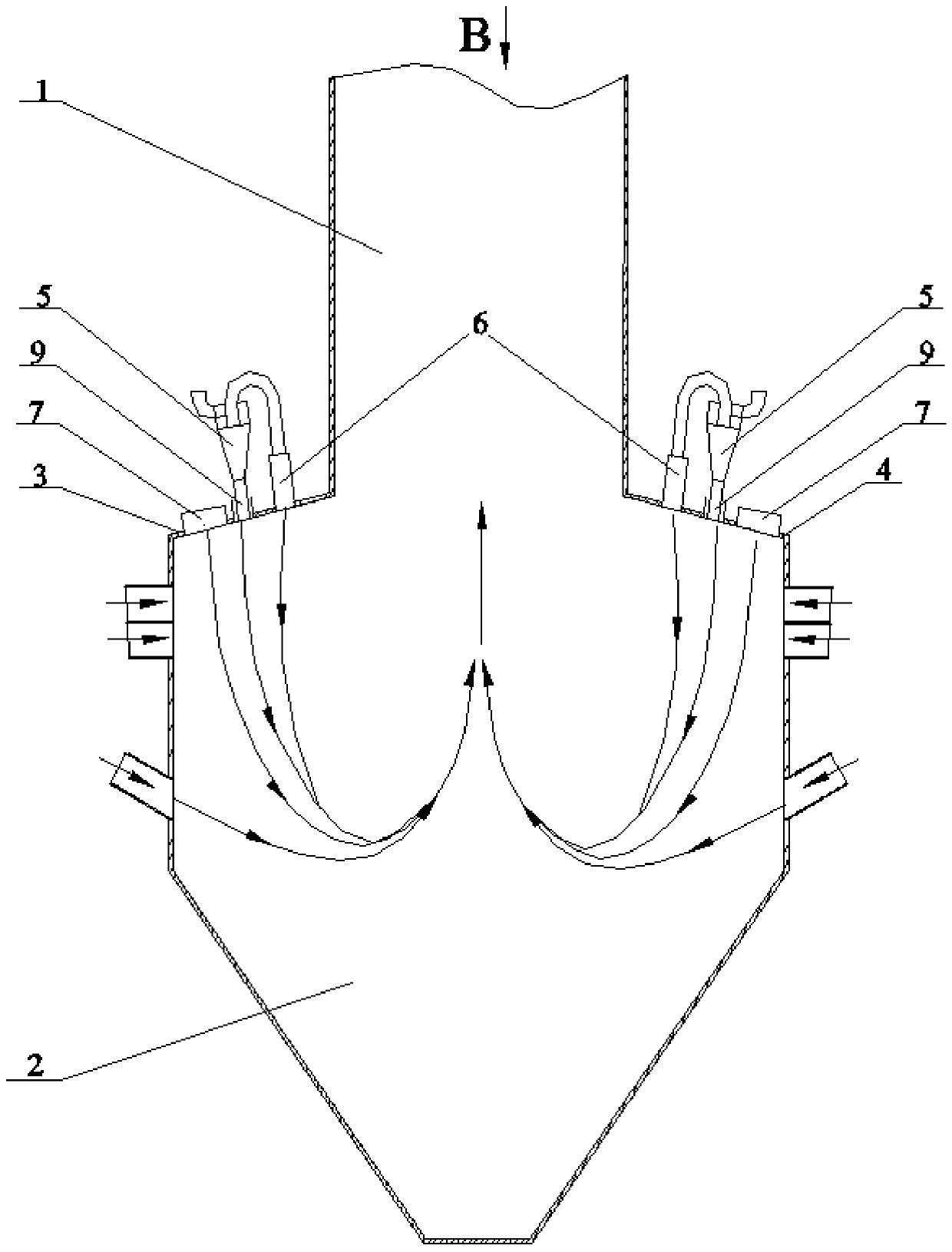

[0031] Specific implementation mode one: combine figure 2 and Figure 4 To illustrate this embodiment, in this embodiment, a W-flame boiler with secondary air on the arch and slit-type exhaust gas interlaced, it includes an upper furnace 1, a lower furnace 2, a front furnace arch 3 and a rear furnace arch 4, an upper furnace 1, a front furnace Furnace arch 3, lower hearth 2 and rear furnace arch 4 constitute the furnace body, which also includes two rows of double cyclone thick and thin pulverized coal burners 5, and each row of double cyclone thick and thin pulverized coal burners 5 includes multiple double cyclone thick and thin coal Pulverized coal burner 5, a plurality of thick and thin pulverized coal burners 5 with double cyclones are arranged symmetrically in a line and installed on the front furnace arch 3 and the rear furnace arch 4, and the double cyclone thick and thin pulverized coal burners 5 include a set of gap type exhaust Air nozzle assembly 6, a group of sl...

specific Embodiment approach 2

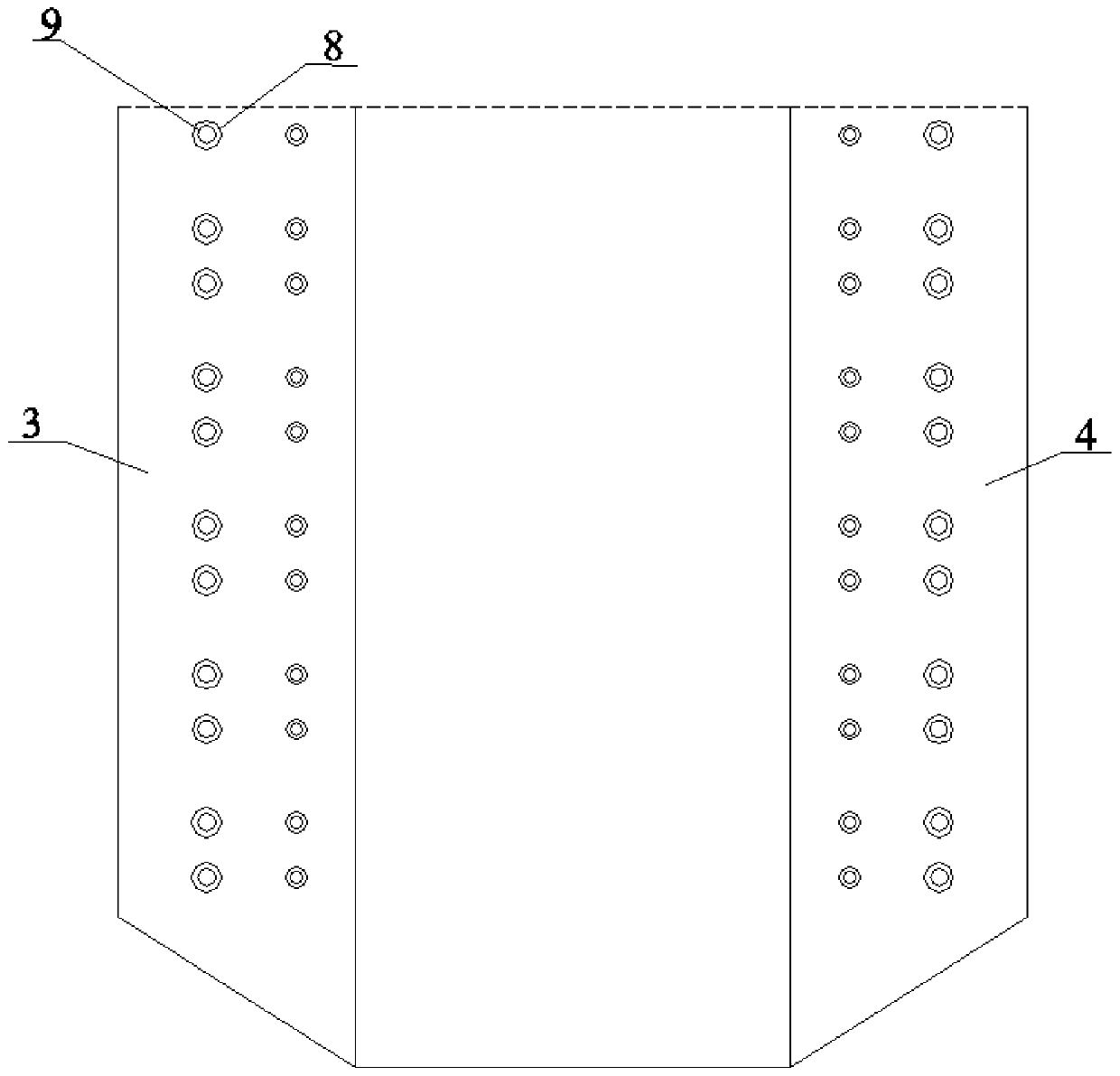

[0032] Specific implementation mode two: combination Figure 4 To illustrate this embodiment, a set of slit-type exhaust nozzle assemblies 6 in this embodiment includes a second slit-type exhaust nozzle 6-2 and two first slit-type exhaust nozzles 6-1; a set of slit-type exhaust nozzles 6-1; The upper secondary air nozzle assembly 7 includes a first slit-type arched secondary air nozzle 7-1 and two second slit-type arched secondary air nozzles 7-2; two first slit-type exhaust air nozzles 6-1 Arranged in parallel, the two second slit-type arch secondary air nozzles 7-2 are arranged in parallel, the first slit-type arch upper secondary air nozzle 7-1 is arranged between the two first slit-type exhaust gas nozzles 6-1 , the second slit-type exhaust gas nozzle 6-2 is arranged between the two second slit-type arched secondary air nozzles 7-2, and the two second slit-type arched secondary air nozzles 7 on the front furnace arch 3 -2 is set close to the front wall of the lower furnac...

specific Embodiment approach 3

[0034] Specific implementation mode three: combination Figure 4 To illustrate the present embodiment, the distance between the centers of the two concentrated pulverized-coal airflow nozzles 9 on each double-cyclone dense-lean pulverized-coal burner 5 described in this embodiment is 3 to 6 times the diameter of the pulverized-coal flow nozzle 9 .

[0035] Other compositions and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com