A preparation process of composite wear-resistant material for brake pads

A wear-resistant material and preparation technology, which is applied in the direction of friction linings, mechanical equipment, gear transmission mechanisms, etc., can solve the problems of reduced braking performance of brake pads, inability to brake effectively, and loss of braking ability, etc., to achieve improved durability Heat, promote orderly arrangement, increase the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

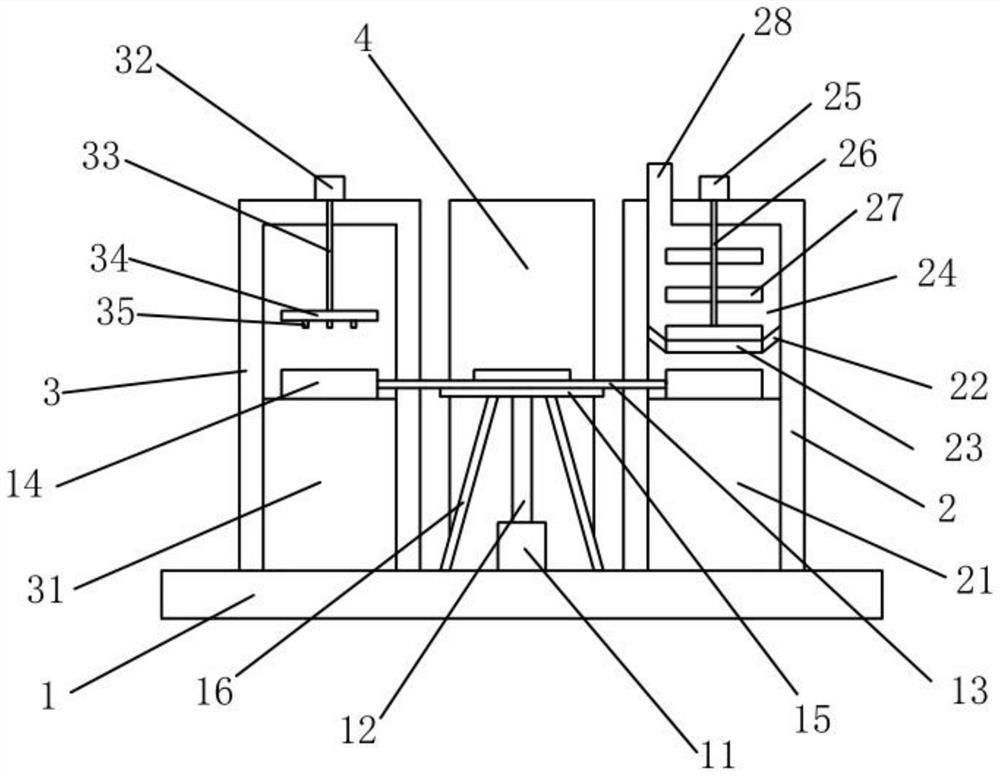

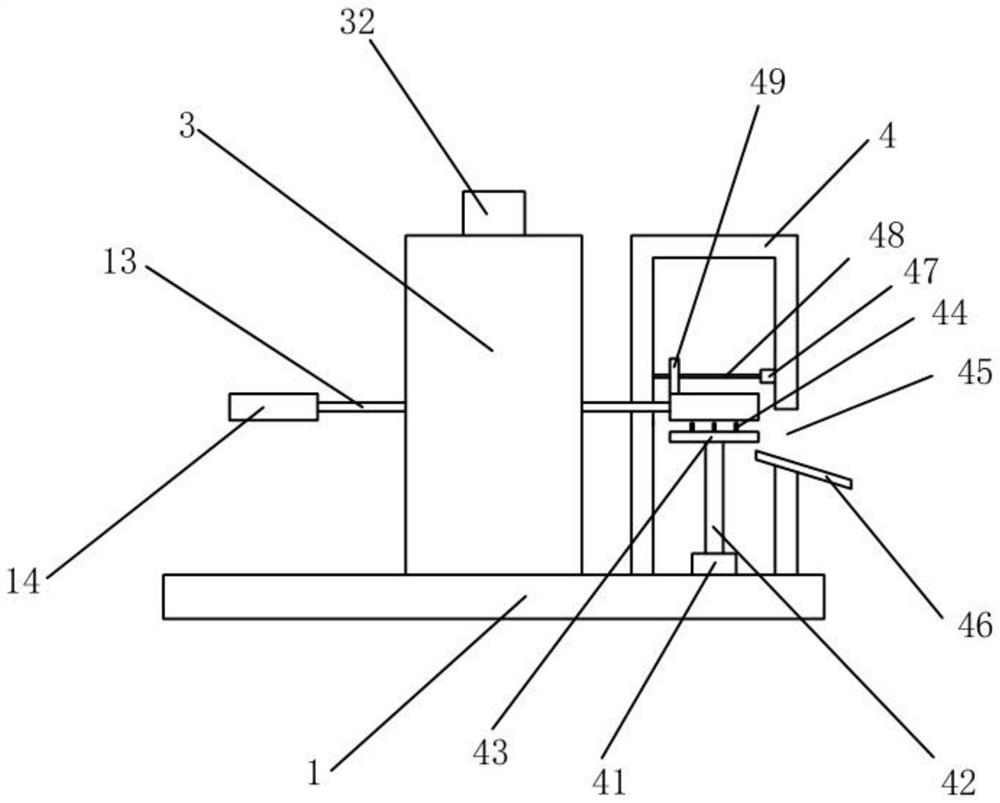

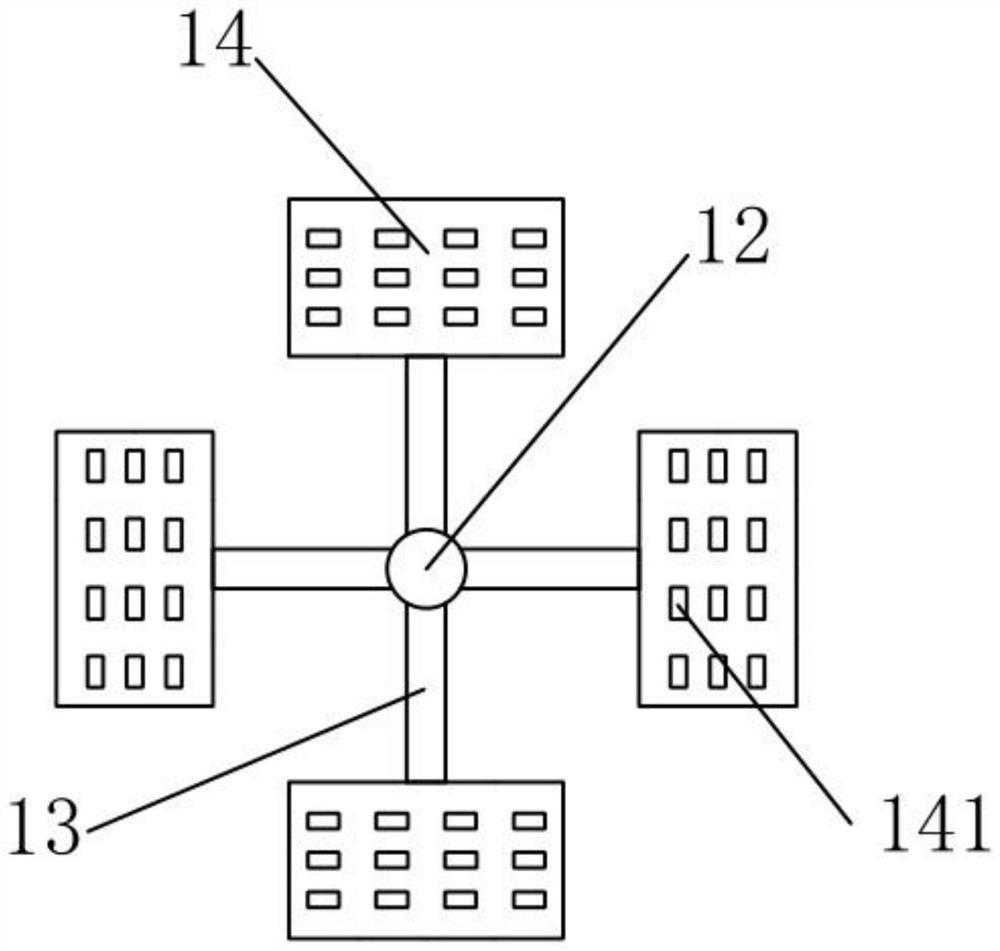

Image

Examples

Embodiment 1

[0047] A preparation process of a composite wear-resistant material for brake pads, the composite wear-resistant material is made of the following raw materials in parts by weight: 15 parts of modified phenolic resin, 10 parts of carbon fiber, 10 parts of sepiolite fiber, 10 parts of coke powder, mica 10 parts of powder, 10 parts of tire powder, 1.5 parts of stearic acid, 0.5 parts of vinyltriethoxysilane, 0.5 parts of aluminum hydroxide;

[0048] The steps of the preparation process of the composite wear-resistant material are as follows:

[0049] Step S1: Weighing the above raw materials by weight, putting the weighed raw materials into an oven, and drying them at a temperature of 80°C until the raw materials are completely dry;

[0050] Step S2: Grinding the dried modified phenolic resin, carbon fiber, sepiolite fiber, crushing the pulverized phenolic resin, carbon fiber, sepiolite fiber, coke powder, mica powder, tire powder, stearic acid, aluminum hydroxide Add it into t...

Embodiment 2

[0058] A preparation process of a composite wear-resistant material for brake pads, the composite wear-resistant material is made of the following raw materials in parts by weight: 25 parts of modified phenolic resin, 25 parts of carbon fiber, 25 parts of sepiolite fiber, 20 parts of coke powder, mica 20 parts of powder, 20 parts of tire powder, 3 parts of stearic acid, 2 parts of vinyltriethoxysilane, 2 parts of aluminum hydroxide;

[0059] The steps of the preparation process of the composite wear-resistant material are as follows:

[0060] Step S1: Weigh the above raw materials in parts by weight, put the weighed raw materials into an oven, and dry them at a temperature of 90°C until the raw materials are completely dry;

[0061] Step S2: Grinding the dried modified phenolic resin, carbon fiber, sepiolite fiber, crushing the pulverized phenolic resin, carbon fiber, sepiolite fiber, coke powder, mica powder, tire powder, stearic acid, aluminum hydroxide Add it into the mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com