Nano fiber for continuously releasing fragrance and preparation method and application of nano fiber

A nanofiber, sustained-release technology, applied in application, fiber chemical characteristics, cellulose/protein conjugated rayon, etc., can solve the problem of difficulty in effectively controlling the release rate, and achieve the maintenance of aroma characteristics, uniform aroma intensity, guarantee safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

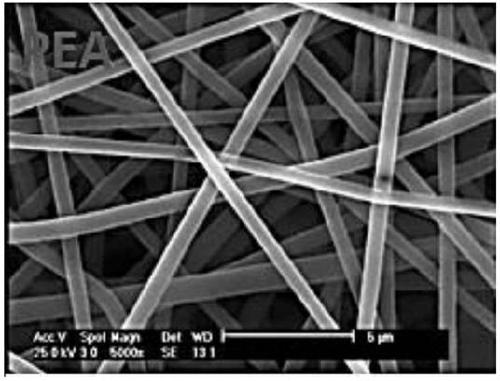

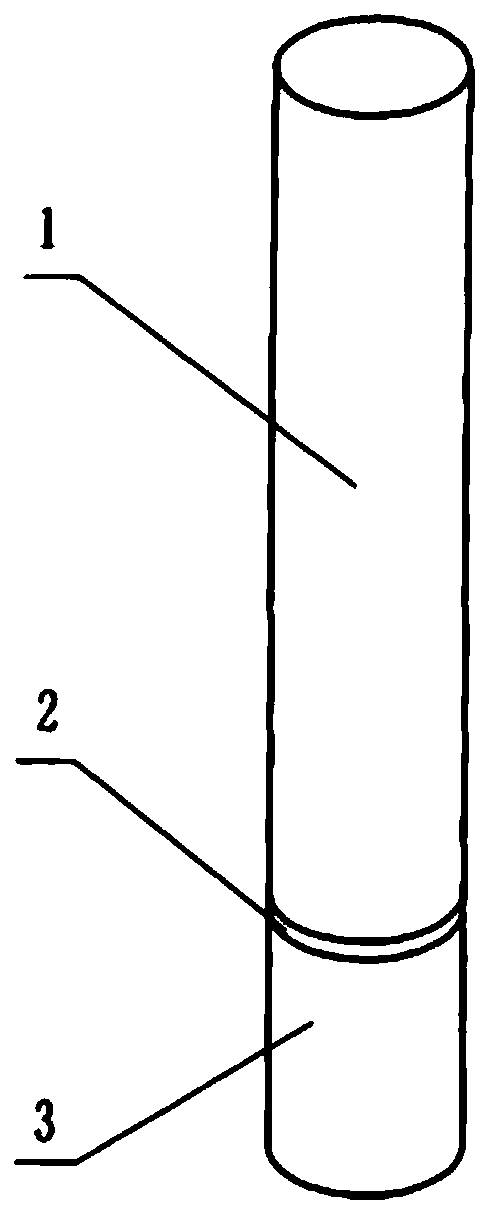

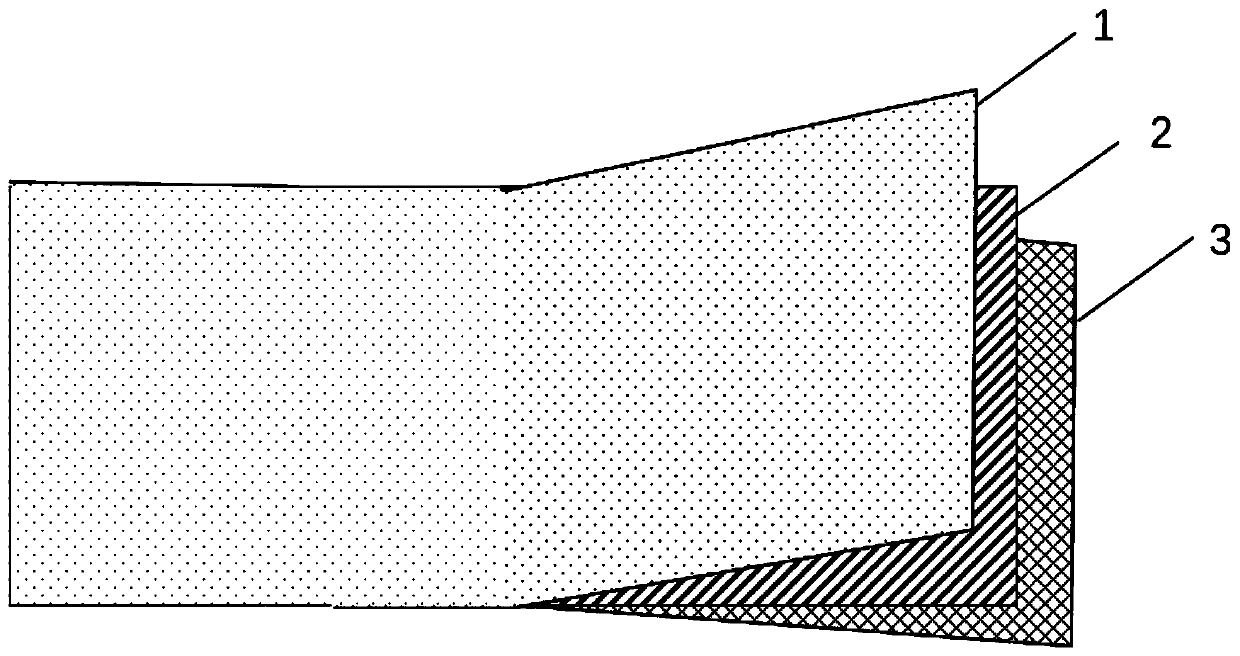

[0041] A long-lasting fragrance nanofiber used for cigarette filters, the slow-release aromatic antibacterial nanofiber is prepared by the following steps:

[0042] (1) Dissolve a certain amount of cellulose acetate into dimethylformamide, dissolve a certain amount of menthol and polyimide into dimethylformamide, then add acetic acid to the solution containing menthol and polyimide In the cellulose solution, and mixed evenly, the spinning solution was prepared. Wherein in the spinning solution, the mass percent concentration of cellulose acetate is 18wt%, the mass percent concentration of menthol is 5wt%, the mass percent concentration of polyimide is 2wt%, and the rest is dimethylformamide.

[0043] (2) In the electrospinning device, the spinning solution is electrospun to obtain nanofibers containing menthol, wherein the spinning solution feed rate is about 0.2ml / min, the electrospinning distance is about 10cm, and the voltage is about 15kV.

[0044] The nanofiber sample p...

Embodiment 2

[0047] A long-lasting fragrance nanofiber used for cigarette filters, the slow-release aromatic antibacterial nanofiber is prepared by the following steps:

[0048] (1) Dissolving a certain amount of polylactic acid into formic acid to prepare a formic acid solution of polylactic acid, adding surfactant sodium dodecylbenzenesulfonate (SDS), stirring evenly, adding jasmone dropwise therein. A certain amount of polyethyleneimine is dissolved in formic acid, stirred evenly, and then added into the formic acid solution of the aforementioned polylactic acid to obtain a spinning solution. Wherein in this spinning solution, the mass percent concentration of polylactic acid is 15wt%, the mass percent concentration of jasmone is 3wt%, the mass percent concentration of polyimide is 1.5wt%, sodium dodecylbenzenesulfonate (SDS ) mass percent concentration is 0.3wt%, and the rest is formic acid.

[0049] (2) In the electrospinning device, the polylactic acid nanofibers comprising jasmone ...

Embodiment 3

[0052] A long-lasting fragrance nanofiber used for cigarette filters, the slow-release aromatic antibacterial nanofiber is prepared by the following steps:

[0053] (1) Dissolving a certain amount of polyacrylonitrile, coffee extract and polypropyleneimine into dimethyl sulfoxide to prepare a spinning solution. In the spinning solution, polyacrylonitrile is 22wt%, coffee extract is 10wt%, polypropyleneimine is 10wt%, and the rest is dimethyl sulfoxide.

[0054] (2) In the electrospinning device, the spinning solution is electrospun to obtain polyacrylonitrile nanofibers containing coffee extract extract, wherein the feeding speed of the spinning solution is about 0.1ml / min, and the electrospinning The distance is about 20cm, the voltage is about 10kV, and attapulgite with 2% volume of the spinning solution is added during spinning to increase the air permeability of the obtained nanofibers.

[0055] The nanofiber sample prepared by the above method was added to a cigarette fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com