A kind of side chain random polyaryl ether sulfone and its preparation method and homogeneous anion exchange membrane

An anion exchange membrane and polyaryl ether sulfone technology, which is applied in the field of homogeneous anion exchange membranes, can solve the problems of reduced anion selectivity and flux, unstable modified layer, low selectivity coefficient, etc., so as to maintain long-term stability performance. , good chemical stability and mechanical properties, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Preparation of 3,3'-dibromo-4,4'-difluorodiphenylsulfone (db-DFPS): Weigh 25.4 g of 4,4'-difluorodiphenylsulfone (0.10 mol) into a 250 mL round bottom flask , and then 150 mL of concentrated sulfuric acid was added, and the mixture was stirred and dissolved at 25 °C in a nitrogen atmosphere. Then, 14.2 g (0.22 mol) of N-bromosuccinimide (NBS) was added in 3 batches at 15 min intervals, and the mixture was rapidly stirred for 6 h. The resulting mixture was poured into ice water (500 mL). The precipitate was obtained by filtration, then washed with 600 mL of deionized water and 100 mL of n-hexane, respectively. Finally, it was purified by crystallization from toluene. Vacuum drying at 60° C. for 12 h yielded 18.3 g of db-DFPS.

[0067] Preparation of modified 4,4'-difluorodiphenylsulfone (m-DFPS): Weigh 8.0 g (19.4 mmol) of 3,3'dibromo-4,4'difluorodiphenylsulfone, 3.5 g (41.2 mmol) 1-hexene, 0.262 g (1.07 mmol) of palladium acetate, 0.2120 g (0.582 mmol) of sodium dip...

Embodiment 1-2

[0074] Preparation of side-chain random polyaryl ether sulfone anion exchange membrane: 2.8 g of the side-chain random polyaryl ether sulfone prepared in Example 1 was dissolved in 60 mL of NMP solvent, and magnetically stirred at 80°C until completely dissolved to obtain Film casting solution: Degas the casting solution, then pour the defoamed casting solution into a clean glass mold, and dry it at 80°C to form a membrane to obtain a homogeneous side chain random polyarylethersulfone anion exchange film with a film thickness of 106 μm.

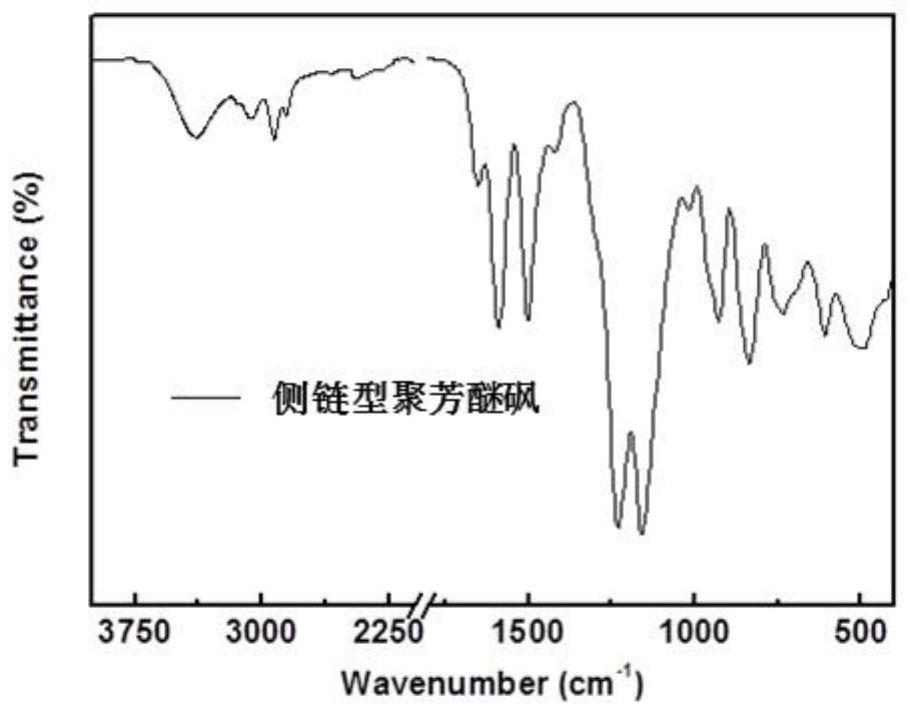

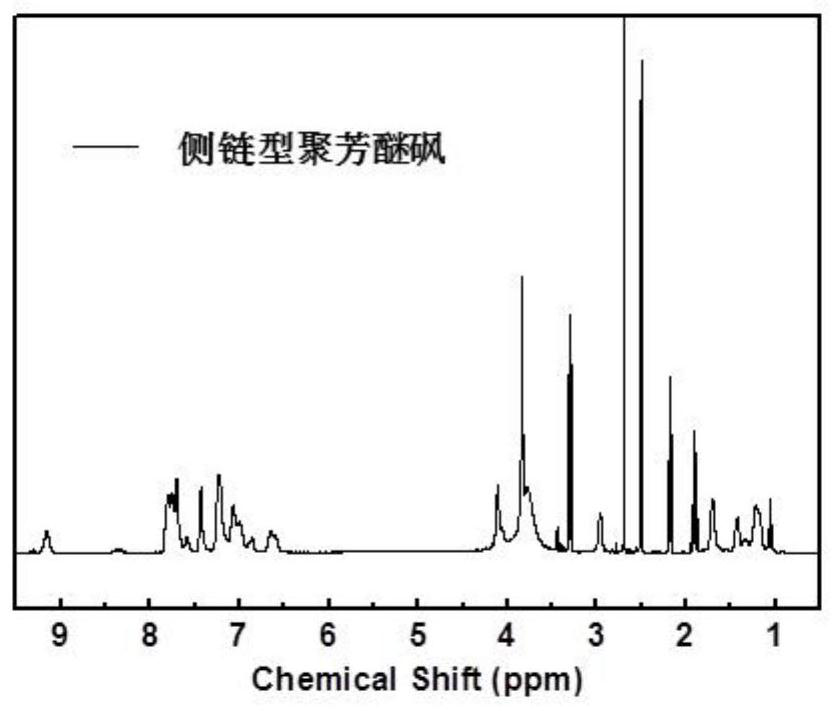

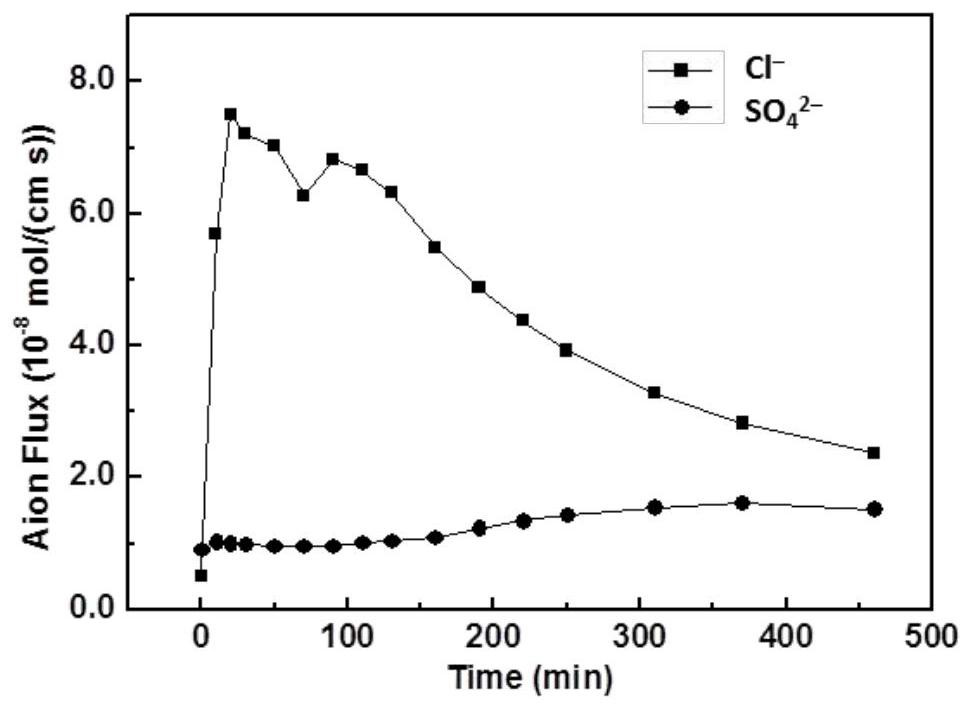

[0075] Using the national standard method, the experimental results show that the IEC of the prepared side-chain random polyarylethersulfone anion membrane is 1.82 mmol g –1 , the migration number is 0.97, the tensile strength is 32.9MPa, the Cl – The maximum permeation flux of 7.5 × 10 –8 mol cm –2 s –1 , Cl – selectivity (Cl – / SO 4 2– ) is 7.1 (for specific test methods, see literature reports: Journal of Membrane Science 574 (2019...

Embodiment 2

[0077] Preparation of 3,3'-dibromo-4,4'-difluorodiphenylsulfone (db-DFPS): The same preparation process as in Example 1 was adopted to obtain db-DFPS.

[0078] Preparation of serially modified 4,4'-difluorodiphenylsulfone (m-DFPS): The same preparation process as in Example 1 was adopted to obtain bis(4-fluoro-3-(4-(1-hexene)) phenyl) sulfone.

[0079] Synthesis of 1,n-bis(4-hydroxyphenyl)alkane (1,n-DBA): using the same preparation process as in Example 1, a pure 1,3-bis(4-hydroxyphenyl) chain was obtained alkyl.

[0080] 1-Bromo-6-imidazolium salt hexane chain (Br-(CH 2 ) 6 Synthesis of -IM): The same preparation process as in Example 1 was adopted to obtain pure 1-bromo-6-methylimidazolium salt-alkane chain.

[0081] Preparation of side-chain random polyaryl ether sulfone: the same preparation process as in Example 1 was adopted, except that 1,3-bis(4-hydroxyphenyl)alkane (8mmol) and 2,2'-bis( 3-Amino-4-hydroxyphenyl)hexafluoropropane (12 mmol) to give a side chain ran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com