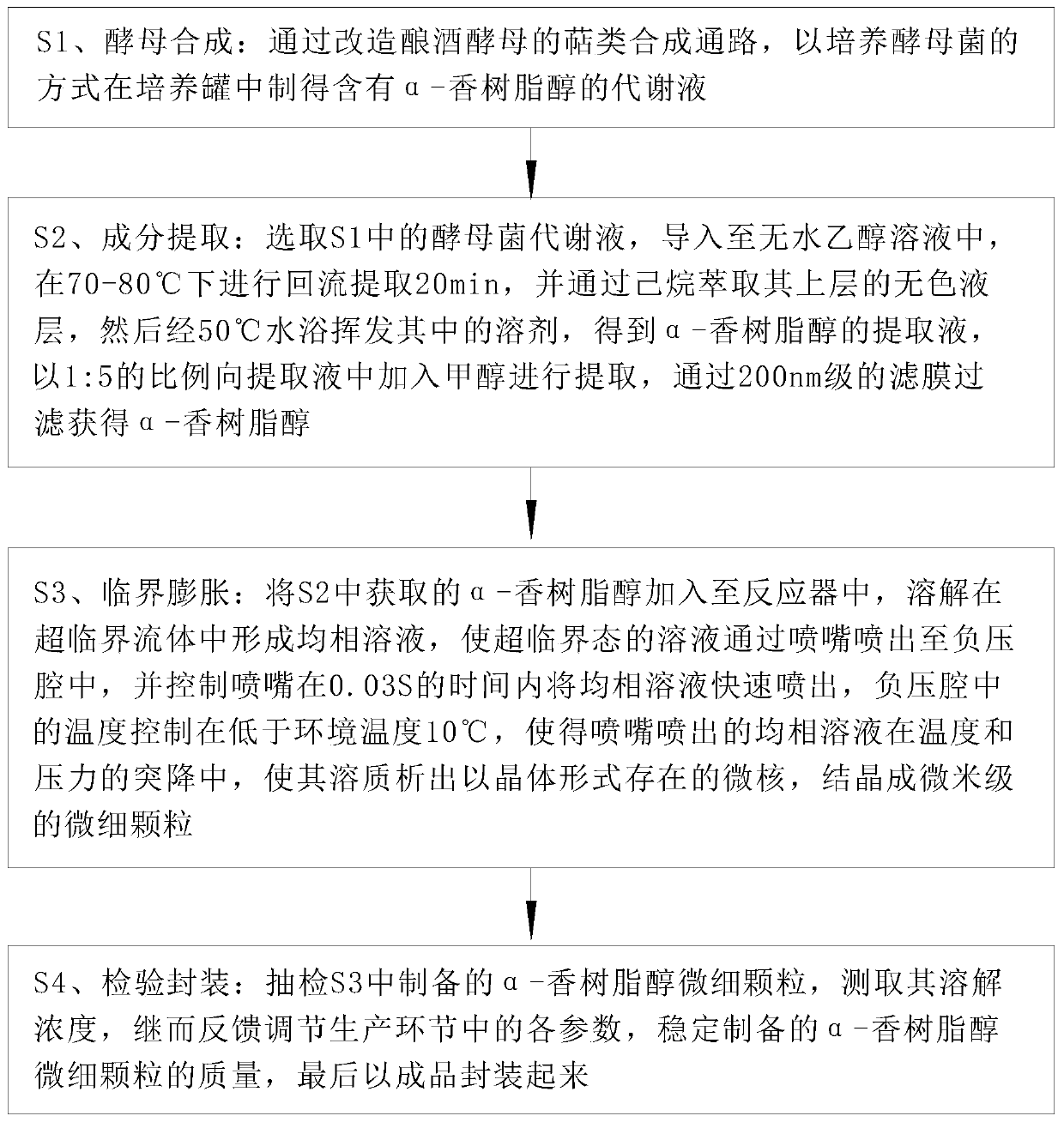

Preparation process of alpha-amyrin fine particles

A technology of balsamol and microfine particles, which is applied in the field of preparation of α-amyresinol microparticles, can solve the problems of the influence of the absorption effect of α-amyresinol microparticles and the failure to effectively control the equilibrium concentration of solutes, etc., and achieve an improvement Stability, the effect of improving the quality of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

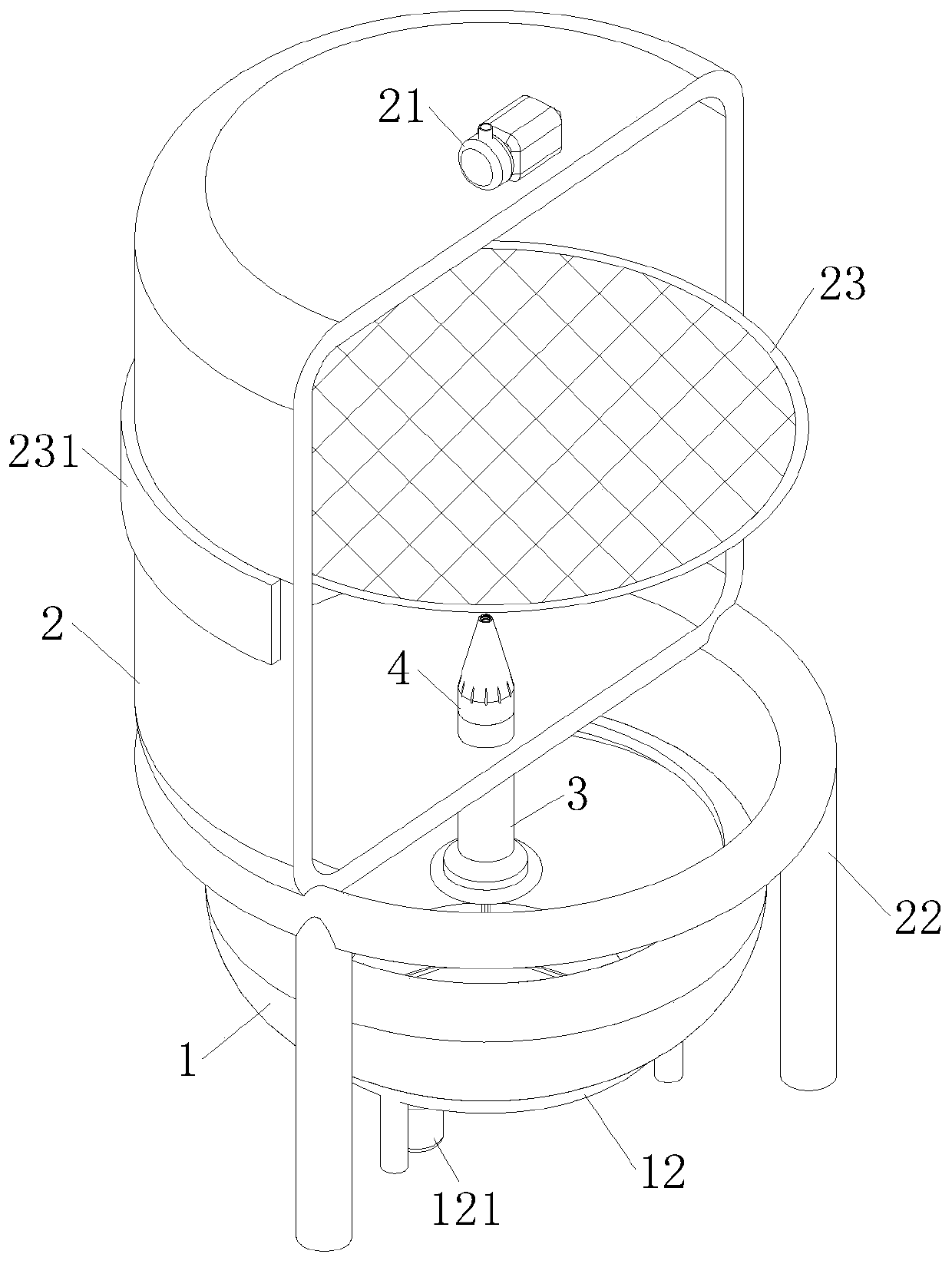

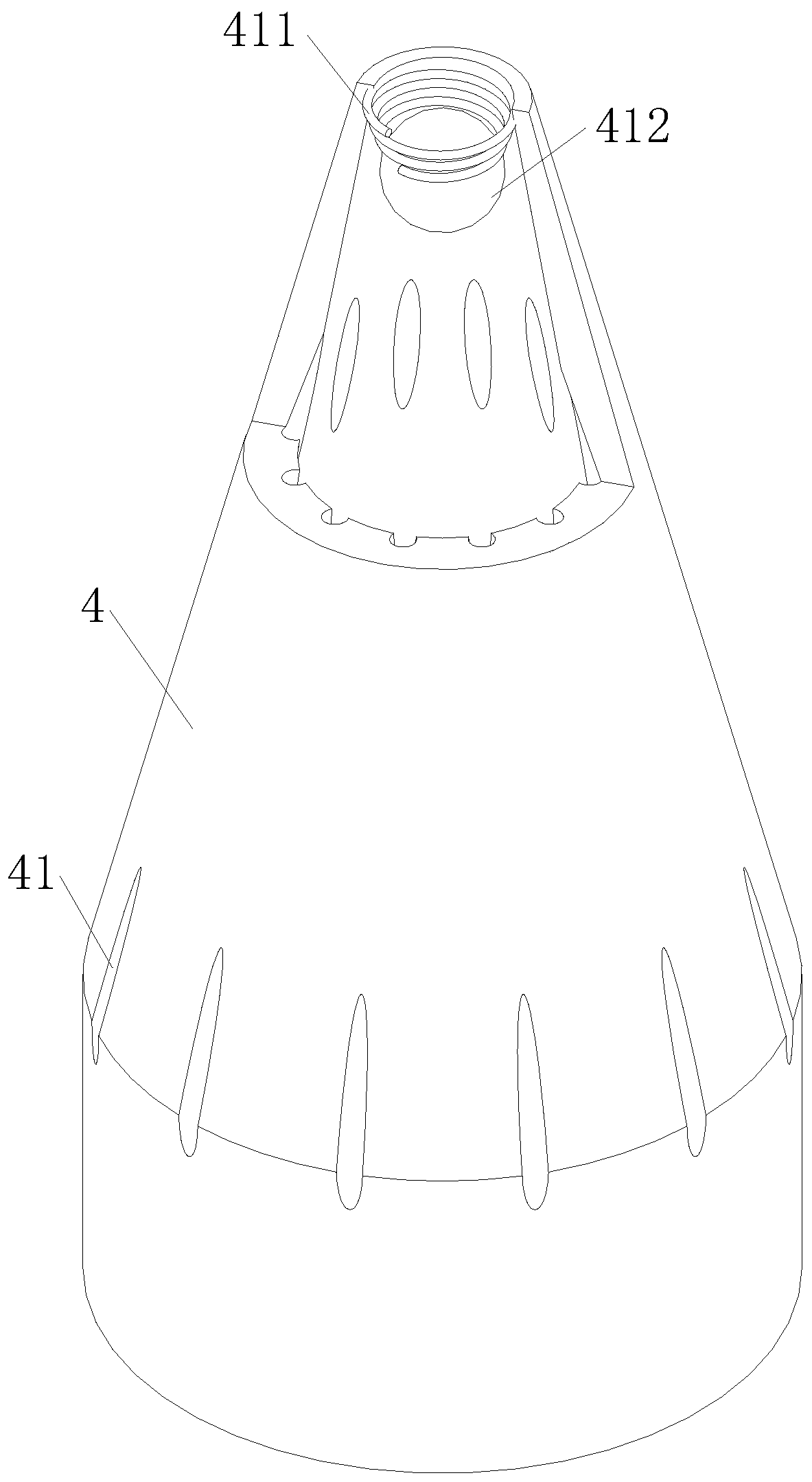

[0038] As an embodiment of the present invention, a spoiler 13 is provided on the inner surface of the bottom of the mixing chamber 1, and the spoiler 13 is vertically fixed on the bottom surface of the mixing chamber 1. 1 is divided into several parts; when in use, the mixing chamber 1 is rotated and installed on the bracket 12, and the solution in the mixing chamber 1 is driven by the drive of the servo motor 121 to vibrate, so as to uniformly mix the α-aromatic resin into it. In the supercritical liquid, it is beneficial to precipitate and generate fine particles in the decompression and expansion of the negative pressure chamber 2; through the spoiler 13 arranged on the bottom of the mixing chamber 1, in the process of the mixing chamber 13 The effect of making the solution oscillated evenly is strengthened, thereby promoting the stable progress of the preparation process of α-amyrin fine particles.

[0039]As an embodiment of the present invention, the spoiler 13 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com