Impregnated adhesive film paper facing aldehyde-free artificial board and preparation method thereof

A technology of impregnating adhesive film paper and wood-based panels, which is applied in special paper, paper, papermaking, etc., can solve the problems of low glue hanging, high degree of crosslinking and high viscosity of decorative paper, and solve the problem of paper damage, molecular weight, etc. Small, medium viscosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

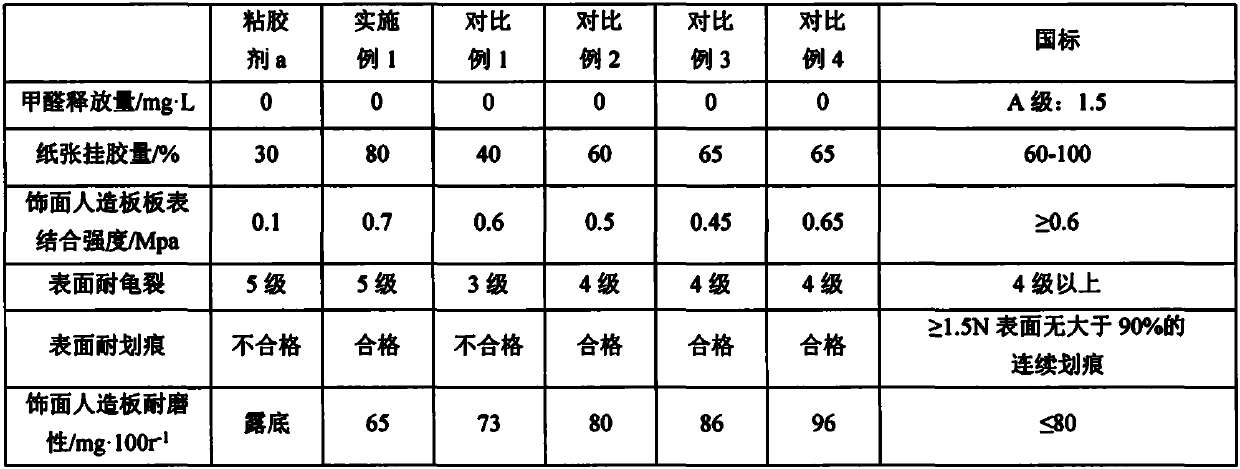

Examples

Embodiment 1

[0032] 1) Add all the pH regulator and deionized water, 1 / 3 soft monomer, 1 / 3 hard monomer, 1 / 3 initiator and all emulsifiers into the reactor, the stirring blade is at an angle of 50° to the horizontal plane, and the paddle The height from the leaf to the bottom of the reaction vessel is 1 / 2 of the liquid level, the stirring speed is 200r / min, and the reaction is stopped immediately after the bluish light is turned to prepare the pre-emulsion.

[0033] 2) Mix the remaining amount of soft monomer and hard monomer evenly, add dropwise to the pre-emulsion with the remaining amount of initiator at 85°C, raise the temperature to 85°C under stirring, and stir at a speed of 150r / min After 30 minutes of dripping, keep the stirring paddle at an angle of 50° to the horizontal plane during the dropping process, and the height between the paddle and the bottom of the reaction vessel is 1 / 2 of the liquid level. After the dropping is completed, keep warm for 20 minutes to prepare a water-ba...

Embodiment 2

[0044] 1) Add all the pH regulator and deionized water, 1 / 3 soft monomer, 1 / 3 hard monomer, 1 / 3 initiator and all emulsifiers into the reactor, the stirring blade is at an angle of 60° to the horizontal plane, and the paddle The height between the leaves and the bottom of the reaction vessel is 1 / 3 of the liquid level, the stirring speed is 150r / min, and the reaction is stopped immediately after the bluish light is turned to prepare the pre-emulsion.

[0045] 2) Mix the remaining amount of soft monomer and hard monomer evenly, add dropwise to the pre-emulsion with the remaining amount of initiator at 85°C, raise the temperature to 85°C under stirring, and stir at a speed of 100r / min After 30 minutes of dripping, keep the stirring paddle at an angle of 60° to the horizontal plane during the dropping process, and the height between the paddle and the bottom of the reaction vessel is 1 / 3 of the liquid level. After the dropping, keep warm for 30 minutes to prepare a water-based acr...

Embodiment 3

[0056] 1) Add all the pH regulator and deionized water, 1 / 3 soft monomer, 1 / 3 hard monomer, 1 / 3 initiator and all emulsifiers into the reactor, the stirring blade is at an angle of 50° to the horizontal plane, and the paddle The height between the leaf and the bottom of the reaction vessel is 1 / 2 of the liquid level, the stirring speed is 180r / min, and the reaction is stopped immediately after the bluish light is turned to prepare the pre-emulsion.

[0057] 2) Mix the remaining amount of soft monomer and hard monomer evenly, add dropwise to the pre-emulsion with the remaining amount of initiator at 85°C, raise the temperature to 85°C under stirring, and stir at a speed of 120r / min After 30 minutes of dripping, keep the stirring paddle at an angle of 50° to the horizontal plane during the dropping process, and the height between the paddle and the bottom of the reaction vessel is 1 / 2 of the liquid level. After the dropping is completed, keep warm for 20 minutes to prepare a wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com