Disinfectant and preparation method and application thereof

A disinfectant and solvent technology, applied in the field of disinfectant and its preparation, can solve the problems of limited force, uncontrollable chlorine release rate, short disinfection time, etc., and achieve the effect of prolonging the use time, significant disinfection effect and effective disinfection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

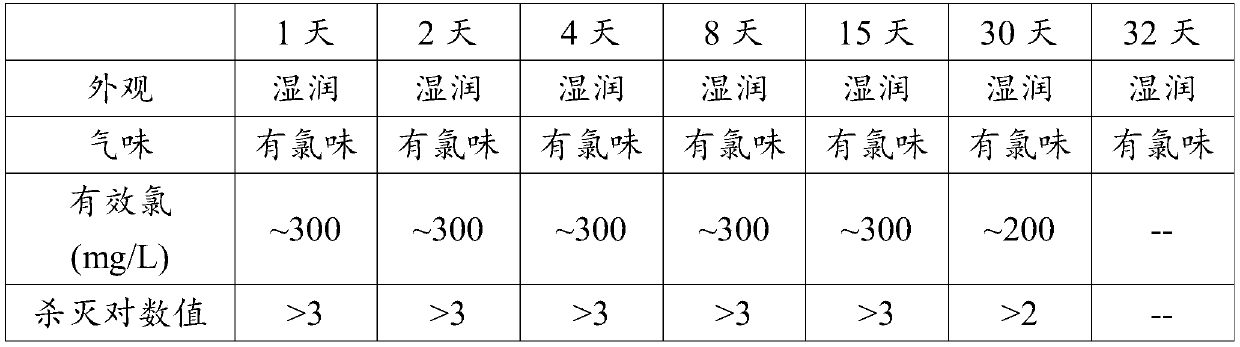

Embodiment 1

[0041] Prepare polyvinyl alcohol and sodium hypochlorite mixed solution, wherein polyvinyl alcohol is 5wt%, sodium hypochlorite 15wt%, ethylene glycol 30wt%.

[0042] The specific configuration method is as follows: weigh 5g polyvinyl alcohol (alcoholysis degree 98%, molecular weight 70,000), 15g sodium hypochlorite, 30g ethylene glycol, 50g deionized water. Add polyvinyl alcohol into 30 g of deionized water, stir at room temperature for 12 h, then stir at 95° C. for 10 h until completely dissolved, and cool to room temperature for later use. Add sodium hypochlorite and ethylene glycol to the remaining 20 g of deionized water and stir until completely dissolved. Mix the polyvinyl alcohol solution and the sodium hypochlorite solution evenly, fill it into a plastic box, put it in a freezer at minus 20°C for 20 hours after packaging, take it out to relax at room temperature for 10 hours, and repeat this process 3 times to obtain the sodium hypochlorite hydrogel. Put the plastic ...

Embodiment 2

[0048] A mixed solution of polyvinyl alcohol and sodium hypochlorite is prepared, wherein the mass percentage of polyvinyl alcohol is 7%, sodium hypochlorite is 25%, and ethylene glycol is 27%.

[0049] The specific configuration method is as follows: weigh 7g polyvinyl alcohol (alcoholysis degree 98%, molecular weight 70,000), 25g sodium hypochlorite, 27g ethylene glycol, 41g deionized water. Add polyvinyl alcohol into 30 g of deionized water, stir at room temperature for 12 h, then stir at 95° C. for 10 h until completely dissolved, and cool to room temperature for later use. Sodium hypochlorite and ethylene glycol were added to the remaining 11 g of deionized water and stirred until completely dissolved. Mix the polyvinyl alcohol solution and the sodium hypochlorite solution evenly, fill it into a plastic box, put it in a freezer at minus 20°C for 20 hours after packaging, take it out to relax at room temperature for 10 hours, and repeat this process 3 times to obtain the s...

Embodiment 3

[0055] A mixed solution of polyvinyl alcohol and sodium hypochlorite is prepared, wherein the mass percentage of polyvinyl alcohol is 5%, and sodium hypochlorite is 15%.

[0056] The specific configuration method is as follows: weigh 5g polyvinyl alcohol (alcoholysis degree 98%, molecular weight 70,000), 15g sodium hypochlorite, 80g deionized water. Add polyvinyl alcohol into 50g of deionized water, stir at room temperature for 12h, then stir at 95°C for 10h until completely dissolved, and cool to room temperature for later use. Sodium hypochlorite was added to the remaining 30 g of deionized water and stirred until completely dissolved. Mix the polyvinyl alcohol solution and the sodium hypochlorite solution evenly, fill it into a plastic box, put it in a freezer at minus 20°C for 20 hours after packaging, take it out to relax at room temperature for 10 hours, and repeat this process 3 times to obtain the sodium hypochlorite hydrogel. Put the plastic box in the outer box pack...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com