Bulk material unmanned loading control method, system and device based on multi-line laser radar

A technology of multi-line laser and control method, which is applied in the direction of control/regulation system, flow control of electric device, controller with specific characteristics, etc. Loading, increasing labor costs and other issues, to achieve the effect of reducing loading costs, avoiding spillage, and improving loading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

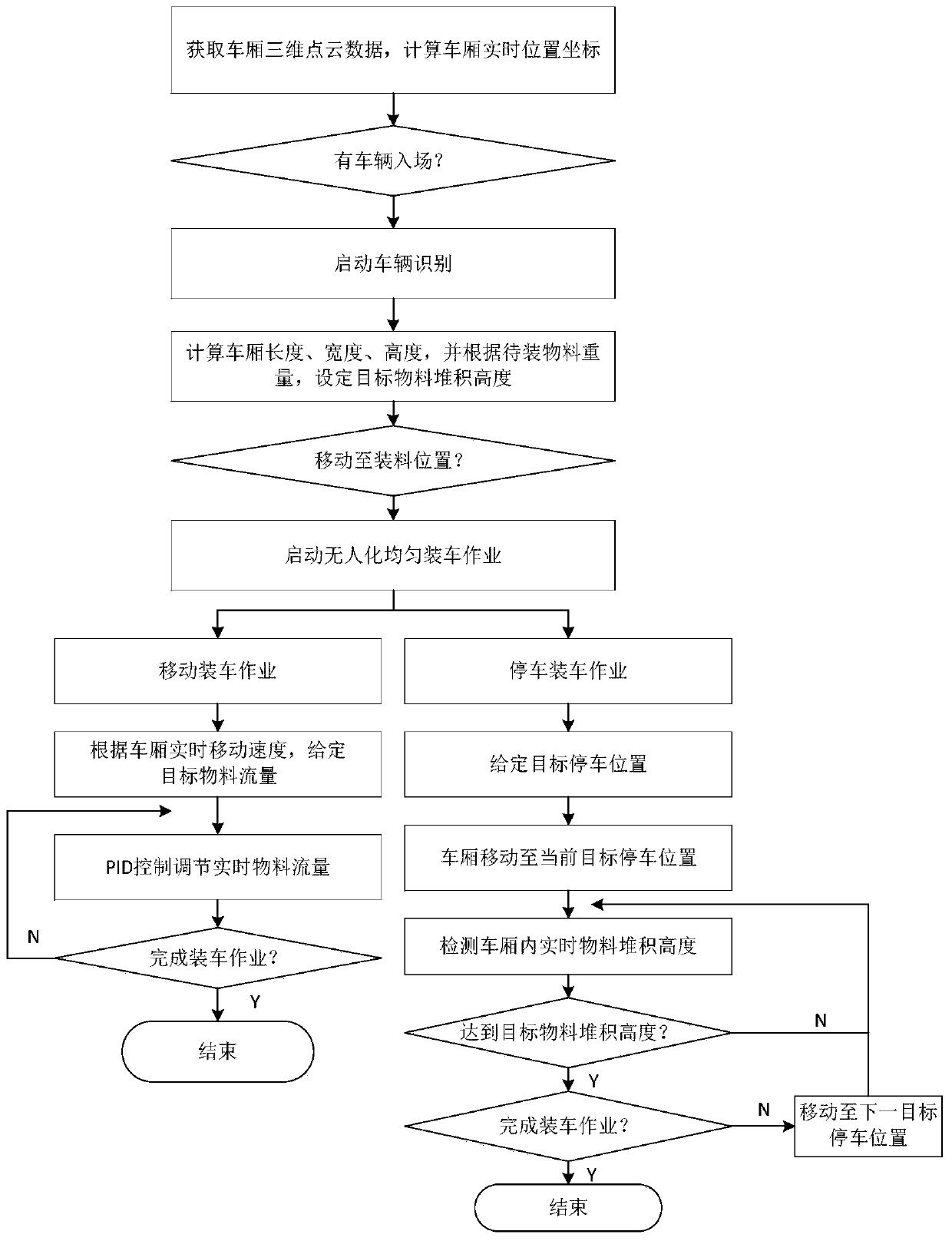

[0046] This embodiment provides a bulk material unmanned loading control method based on multi-line laser radar, such as figure 1 shown, including:

[0047] S1: Obtain the 3D point cloud data of the carriage collected by the multi-line laser radar in real time, establish the 3D data model of the carriage, and calculate the real-time position coordinates of the carriage;

[0048] S2: After detecting that the compartment enters the set position of the bulk material yard, it is judged that a vehicle enters, and vehicle identification is started;

[0049] S3: Calculate the length, width and height of the compartment according to the real-time three-dimensional point cloud data of the compartment, and set the target material accumulation height of the compartment to be loaded according to the weight of the material to be loaded;

[0050] S4: When it is judged that the compartment moves to the loading position, and it is detected that the compartment does not deviate from the drivi...

Embodiment 2

[0086] This embodiment provides a bulk material unmanned loading control system based on multi-line laser radar, including:

[0087] The 3D modeling module is used to obtain the 3D point cloud data of the car collected by the multi-line laser radar in real time, and establish the 3D data model of the car;

[0088] The identification and judgment module is used to calculate the real-time position coordinates of the carriage. When it is detected that the carriage enters the set position of the bulk material yard, it is judged that there is a vehicle entering, and the vehicle identification is started;

[0089] The parameter setting module is used to calculate the length, width and height of the carriage according to the real-time three-dimensional point cloud data of the carriage, and set the target material accumulation height of the carriage to be loaded according to the weight of the material to be loaded;

[0090] The loading start module is used to start the unmanned unifor...

Embodiment 3

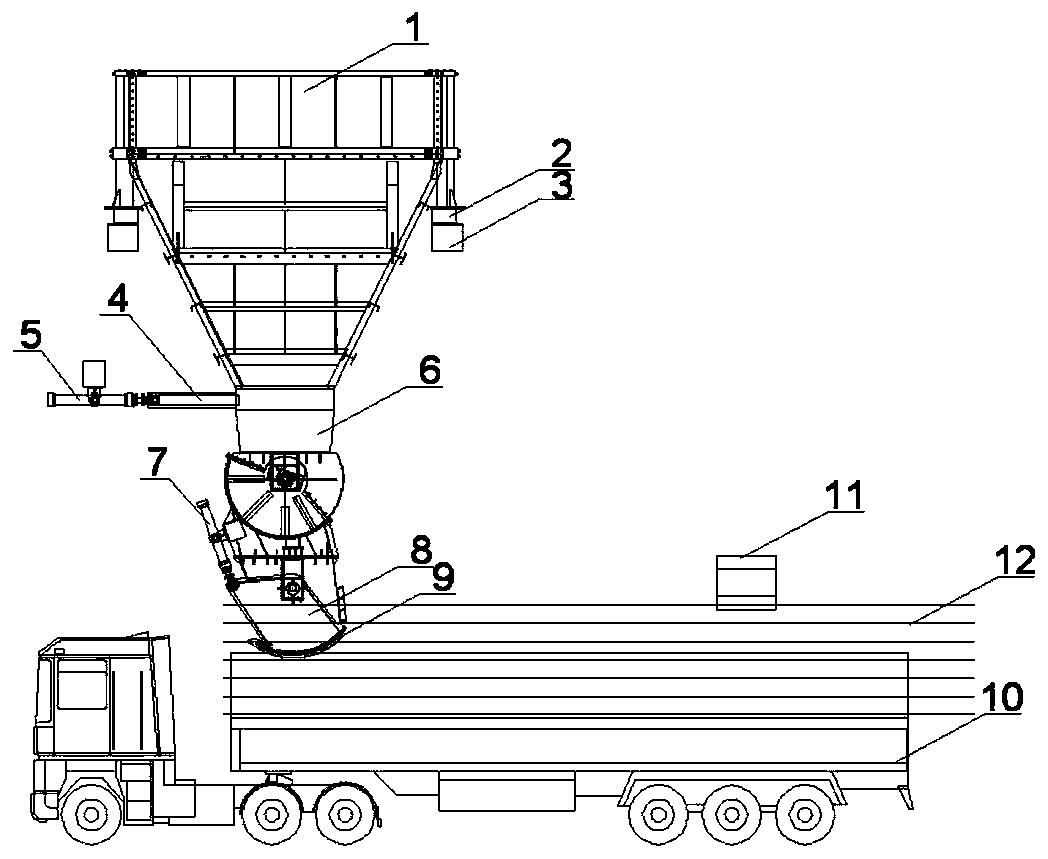

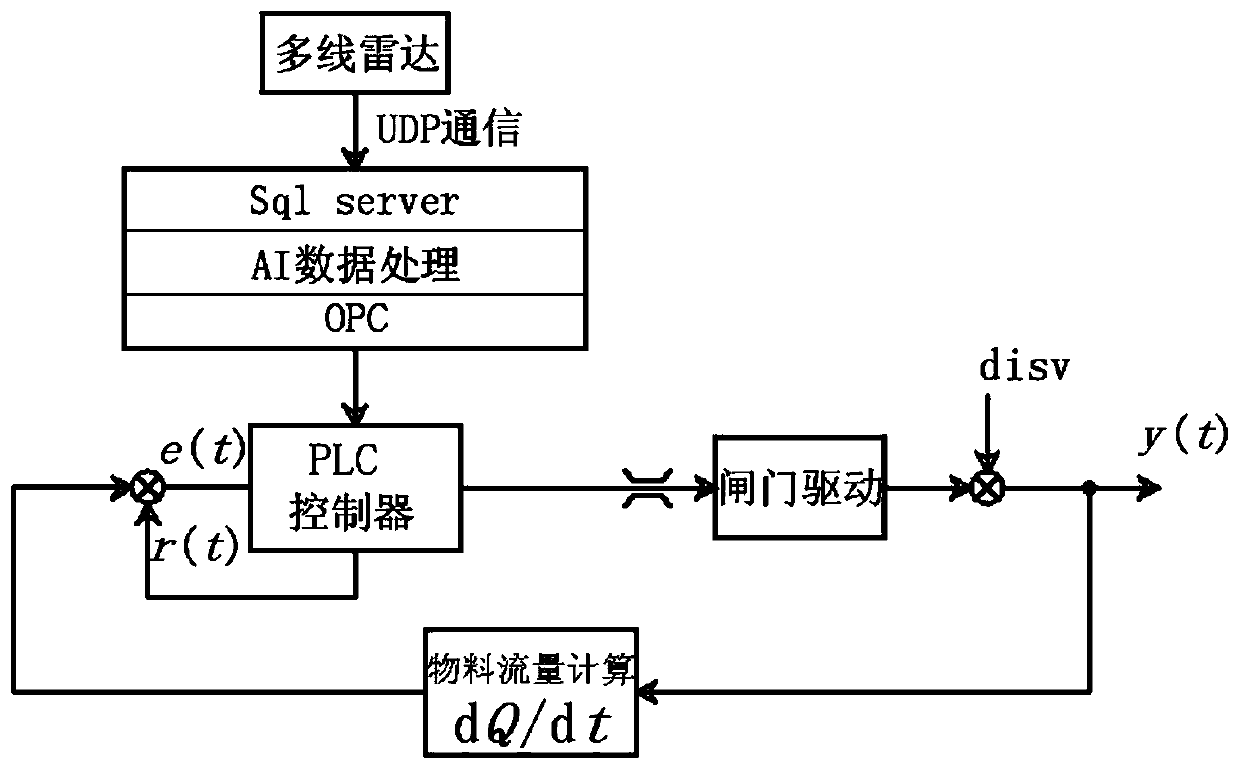

[0104] This embodiment provides a bulk material unmanned loading control device based on multi-line laser radar, such as image 3 As shown, comprising: multi-line laser radar, background server and PLC controller, described background server is arranged with point cloud database;

[0105] The multi-line laser radar is installed at a set height on the side of the carriage, and is used to collect the three-dimensional point cloud data of the carriage in real time, and store it in the point cloud database of the background server;

[0106] The background server is used to realize the control method described in claim 1;

[0107] The PLC controller communicates with the background server to obtain the three-dimensional data information of the compartment analyzed by the background server, and adopts PID control to adjust the material flow in the mobile loading operation.

[0108] The multi-line laser radar adopts the 360-degree circular scanning method of multiple laser beams to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com