A slope assist system based on electro-hydraulic braking and its control method

A technology of hydraulic braking and auxiliary systems, which is applied in the field of automobile braking systems, and can solve problems such as the hidden danger of oil leakage caused by increased pipeline oil pressure, gradual withdrawal of braking force, and increased loading costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in detail below according to the accompanying drawings, which is a preferred embodiment among various implementations of the present invention.

[0043] The aforementioned and other technical contents of the present invention will be clearly presented in the following detailed description of preferred embodiments with reference to the drawings. Through the description of specific implementation methods, the technical means and functions adopted by the present invention to achieve the intended purpose can be understood more deeply and specifically. However, the attached drawings are only for reference and illustration, and are not intended to limit the invention.

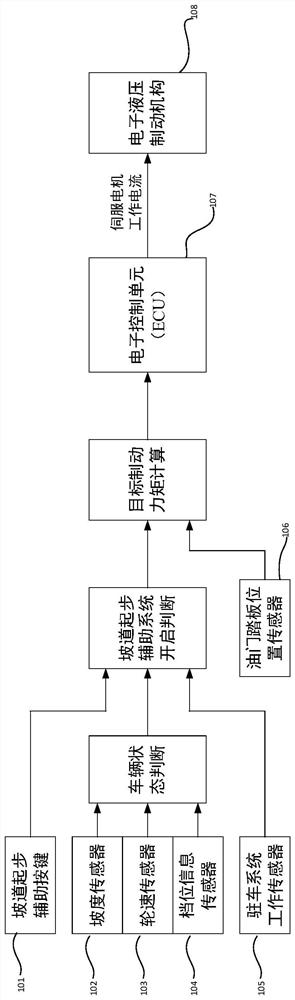

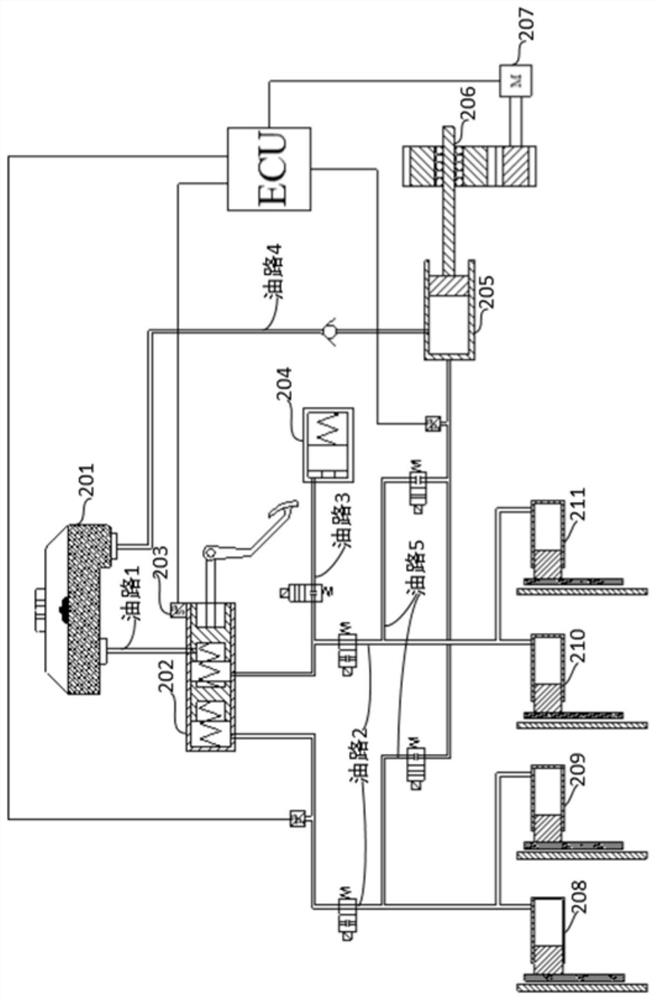

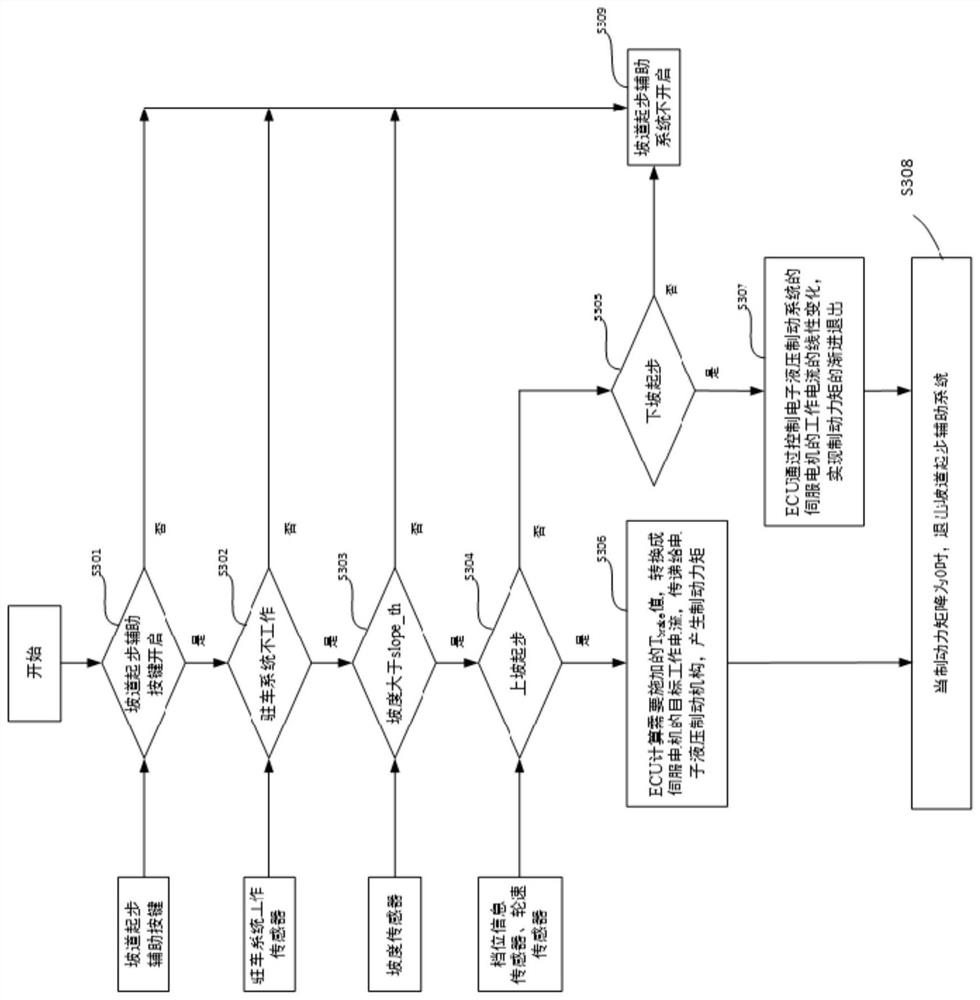

[0044] Such as figure 1 As shown, a hill start assist system based on electronic hydraulic braking includes: a hill start assist button 101 for reflecting the driver's intention to turn on the hill start assist system, a slope sensor 102, a wheel speed sensor 103, a gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com