Method and device for leveling and anti-slipping of an elevator

A leveling and elevator technology, which is applied to the leveling anti-slipping of elevators. The device field used in the above-mentioned elevator leveling anti-slipping method can solve the problems of poor application stability and failure to prevent the car, reaching the limit of use The effect of small resistance, improving operation stability, and ensuring the safety of life and property

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

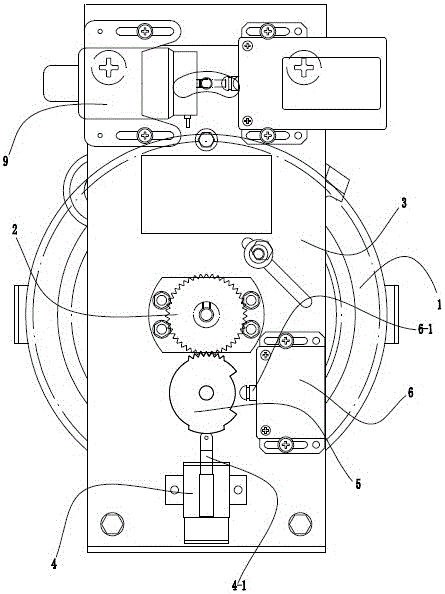

[0035] The anti-slipping method for leveling an elevator provided in this embodiment adopts:

[0036] A friction wheel 2 that rotates synchronously with the sheave 1 in the elevator speed governor,

[0037] A normally open control circuit controls the first electromagnet 4 through the unlocking signal of the car door lock,

[0038] a second electromagnet 9 that triggers the emergency braking device of the elevator car,

[0039] A cam assembly 5 whose cam 5-2 can be in contact with the friction wheel 2 and achieve mutual transmission under the thrust of the iron core 4-1 of the first electromagnet 4,

[0040] And a contact 6-1 is located on the running track of the cam 5-2 in the above-mentioned cam assembly 5, and is connected with the limit switch 6 of the normally open control loop of the second electromagnet 9;

[0041] Wherein, when the elevator car is running normally in the hoistway, the above-mentioned normally open control loop of the first electromagnet 4 does not r...

Embodiment 2

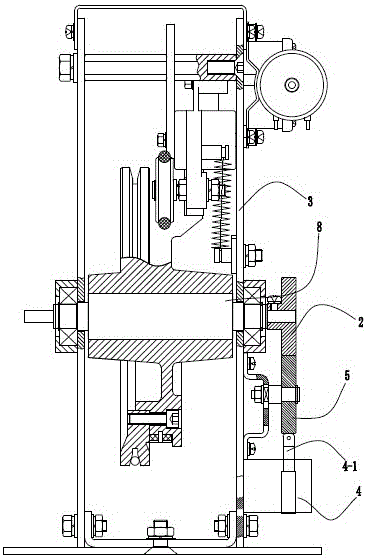

[0047] The leveling anti-slip method and device of an elevator provided in this embodiment are generally consistent with the method and device in the above-mentioned embodiment 1, such as image 3 As shown, only the cam assembly 5 in the flat floor anti-slip device provided in this embodiment also includes a shaft pin 5-3, a lock nut 5-4, a lock block 5-5, a reset Extension spring 5-6 and a return torsion spring 5-7, and guide groove 5-8 is opened on the installation panel of its base 5-1, and above-mentioned axle pin 5-3 penetrates in this guide groove 5-8 , and reciprocate up and down in the guide groove 5-8, and its axial direction is limited by the lock nut 5-4 and the lock block 5-5, the lock block 5-5 is located on the installation panel The cam 5-2 in the above-mentioned cam assembly 5 is sleeved on the shaft pin 5-3, and is located on the outside of the above-mentioned locking block 5-5, and is limited by the chuck 5-9. The above-mentioned reset pull One end of the sp...

Embodiment 3

[0050] The leveling anti-slip detection method and detection device of an elevator provided in this embodiment are generally consistent with the detection method and detection device in the above-mentioned embodiment 2, as Figure 4 and Figure 5 As shown, only the detection device in this embodiment also includes a positioning device 7, which is mainly composed of a positioning rod 7-2, a return spring 7-3 and a positioning base 7-1, and the positioning rod 7- One end of 2 is provided with a limit head 7-4, and the above-mentioned positioning base 7-1 is fixed on the speed limiter side plate 3, and a preset hole is opened on the positioning base 7-1, and the above-mentioned positioning rod 7-2 runs through the preset hole, the above-mentioned return spring 7-3 is connected in series on the above-mentioned positioning rod 7-2, one end of which is connected to the bottom surface of the limit head 7-4, and the other end is connected to the bottom surface of the stopper 7-4. On ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com