Evaporation source of vacuum evaporation equipment

An evaporation source and evaporation technology, which is used in vacuum evaporation plating, sputtering plating, ion implantation plating, etc., can solve the problems of poor process consistency and repeatability, and achieve the goal of reducing raw material cost and reducing composition deviation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The above solution will be further described below in conjunction with specific embodiments. It should be understood that these examples are used to illustrate the present invention and not to limit the scope of the present invention. The implementation conditions used in the examples can be further adjusted according to the conditions of specific manufacturers, and the implementation conditions not indicated are usually the conditions in routine experiments.

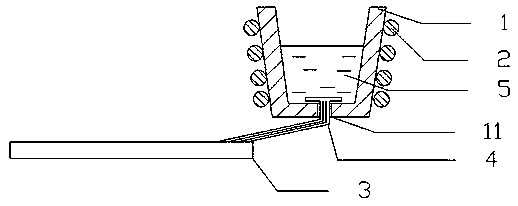

[0024] Such as figure 1 As shown, the evaporation source of the vacuum evaporation equipment of the present invention includes: a crucible 1 , a heating part 2 , an evaporation part 3 , and a drainage beam 4 .

[0025] Wherein, the crucible 1 is a hollow circular platform with an opening at one end, and the evaporation raw material 5 is contained in the above-mentioned crucible 1; preferably, the shape of the above-mentioned crucible 1 can also be a cylinder, a cone, etc.; the heat-resistant temperature of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com