Sealing hook embedding material for coke oven gaps and manufacturing method thereof

A manufacturing method and gap technology, applied to the coke oven door/closer, coke oven heating, coke oven, etc., can solve the problems of coke oven sealing hook inserts, use, solvent volatilization, etc., to reduce the furnace door frame Effects of smoke and fugitive emissions, improvement of coke oven environment, and improvement of sealing degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

[0054] Embodiment 1-6 is used for the sealing hook insert of coke oven gap to adopt following steps to manufacture:

[0055] To prepare nano-silica sol, when configuring nano-silica sol, NaOH solution can be used to adjust the pH value of nano-silica sol to 9-10;

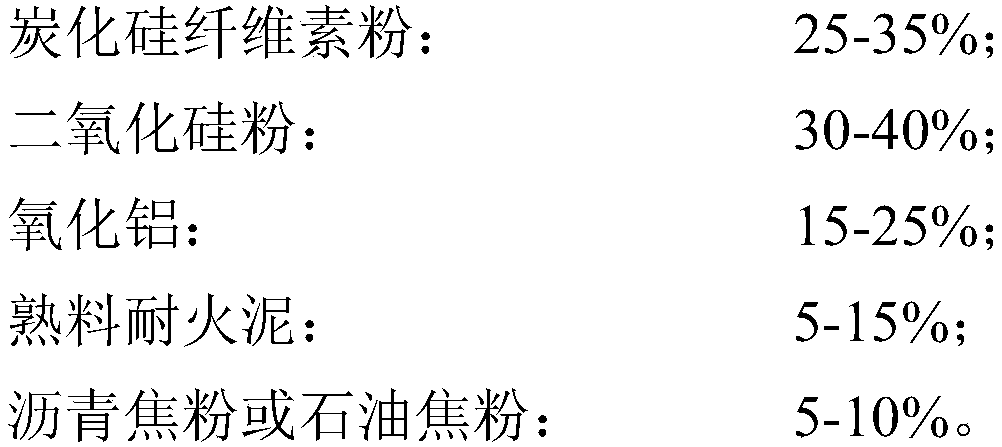

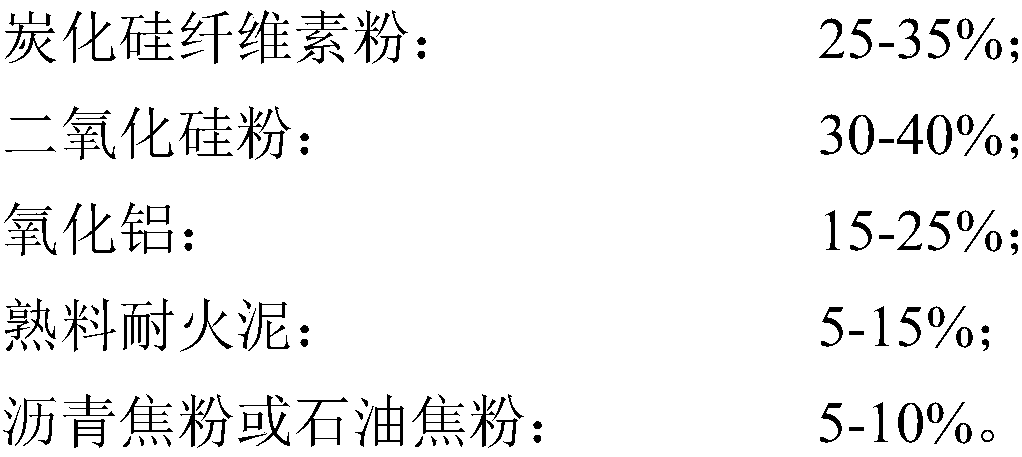

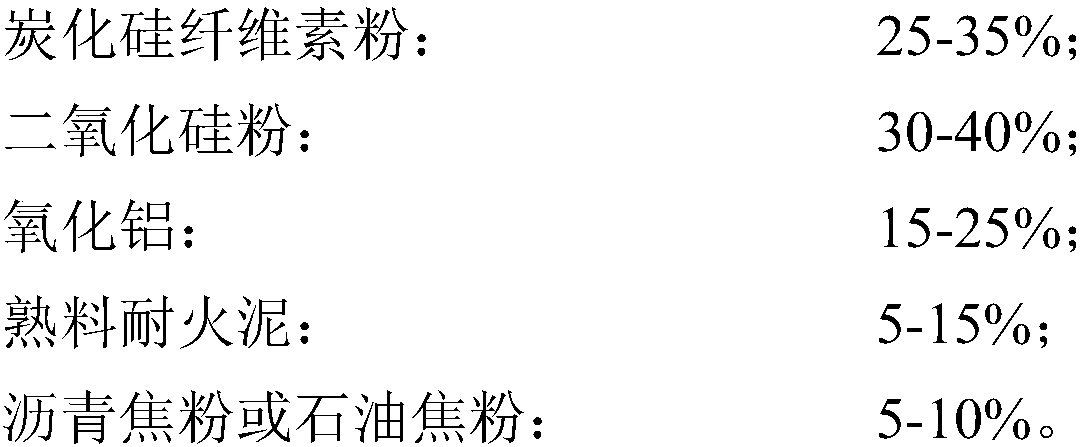

[0056] The filler is made of carbonized silicon cellulose powder, silica powder, alumina, clinker refractory mud and asphalt coke powder or petroleum coke powder;

[0057] Slowly add nano-silica sol while stirring the filler, and stir evenly. During the stirring process, dust can be avoided, and a semi-solid sealing hook insert can be made;

[0058] The sealing and interlocking material of Examples 1-6 is composed of nano-silica sol and filler, wherein the filler is composed of carbonized silicon cellulose powder, silica powder, alumina, clinker refractory mud and asphalt coke powder or petroleum coke powder, Nano-silica sol accounts for 25-35% of the mass percentage of the sealing and hooking material, and the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com