Preparation and application of a kind of denitrification and denitrification embedded bio-ring active packing

An active filler, nitrification and denitrification technology, applied in biochemical equipment and methods, biological water/sewage treatment, water pollutants, etc., can solve problems such as difficult high efficiency, high technical requirements, production cost and production efficiency , to achieve the effect of good fluidization state, single weight reduction, and reduction of requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

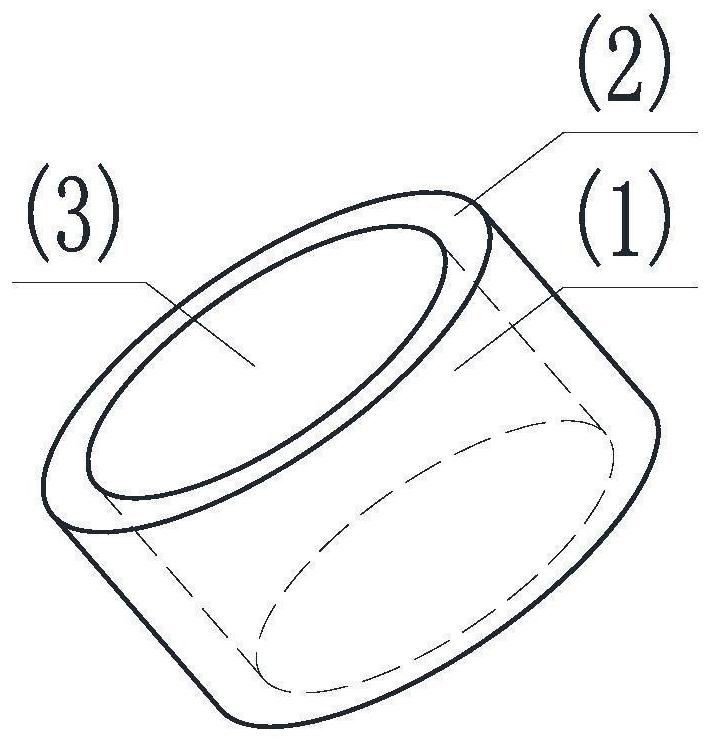

Image

Examples

Embodiment 1

[0023] 1. Preparation of filler

[0024] The directional culture of denitrifying bacteria was carried out with the remaining sludge in the secondary sedimentation tank of the urban sewage plant as the bacterial source, and the denitrifying bacteria suspension after screening and enrichment culture was centrifugally dehydrated and concentrated to obtain a denitrifying bacteria concentrated solution with a bacterial concentration of 10 8 -10 9 individual / mL.

[0025] Utilize 90 ℃ of water dissolving PVAs to be prepared into the PVA solution of 40% mass concentration; According to (PVA addition is 25%; Denitrifying bacteria culture 50%; Diatomite 15%; 100 mesh wood activated carbon 4%; Calcium carbonate 5% ; The remaining 1% is sodium phosphate, magnesium sulfate, ferrous sulfate, manganese sulfate, and ZnSO 4 ·7H 2 O. NaMoO 4 2H 2 O, CoCl 2 ·6H 2 O, NiCl 2 ·6H 2 O, CuSO 4 ·5H 2 The mixture composed of O (percentage by weight: 5:21:30:43:0.4:0.15:0.15:0.15:0.15)) is mi...

Embodiment 2

[0031] 1. the preparation of filler (1) (same as example 1)

[0032] 2. Application of high-concentration chemical wastewater denitrification bioactive filler ( Nitrate concentration 2400mg / L )

[0033] Add 100 suspended balls prepared in 1. with filler (1) to the reactor with an effective volume of 120L, and finally form denitrifying bacteria embedded bioactive filler. The filling rate is 12.5%, and the water temperature is 28±2°C. , HRT= 8h , the pH is 7.5-8.0, the raw water is high-concentration wastewater produced by chemical fertilizer production, the nitrate concentration is 2400±200mg / L, the denitrification carbon source is sodium acetate, and the dosage ratio is 3.5-4.0 times that of nitrate nitrogen. The denitrification reactor Every 5 days of continuous operation, the packing is flushed by backwashing, and the nitrate nitrogen in the effluent of the reactor is measured on time. The test results of the effluent showed that after 15 days of culture recovery, the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com