Preparation and application of anaerobic hydrolytic acidification composite bacterium embedded bioactive filler

A technology of hydrolysis, acidification and biological activity, applied in anaerobic digestion treatment, water pollutants, biological water/sewage treatment, etc. The effect of good state, improved stability and increased toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Preparation of hydrolytic acidified culture culture

[0026] Take the concentrated excess sludge (water content 97%) of the existing sewage treatment plant, and add the soybean product processing wastewater sediment under the low-intensity stirring condition of 80r / min (adjust the dosage according to the remaining amount of protein to maintain The remaining protein content is 0.2mg / L as the standard, and the sediment is added), and the trace element solution is added at 5mL / L (trace element composition: ZnSO 4 ·7H 2 O: 0.50mg / L; NaMoO 4 2H 2 O: 0.12mg / L; CoCl 2 ·6H 2 O: 0.20mg / L; MnSO 4 ·H 2 O: 0.50mg / L; NiCl 2 ·6H 2 O: 0.70mg / L; CuSO 4 ·5H 2 O: 0.60mg / L; FeCl 3 ·6H 2 (0:0.80mg / L), detect the pH change, control the pH in the range of 6.5-7.0, run continuously for 7 days, dehydrate and concentrate the culture to a water content of 80%, and finally form a hydrolytic acidifying bacteria culture.

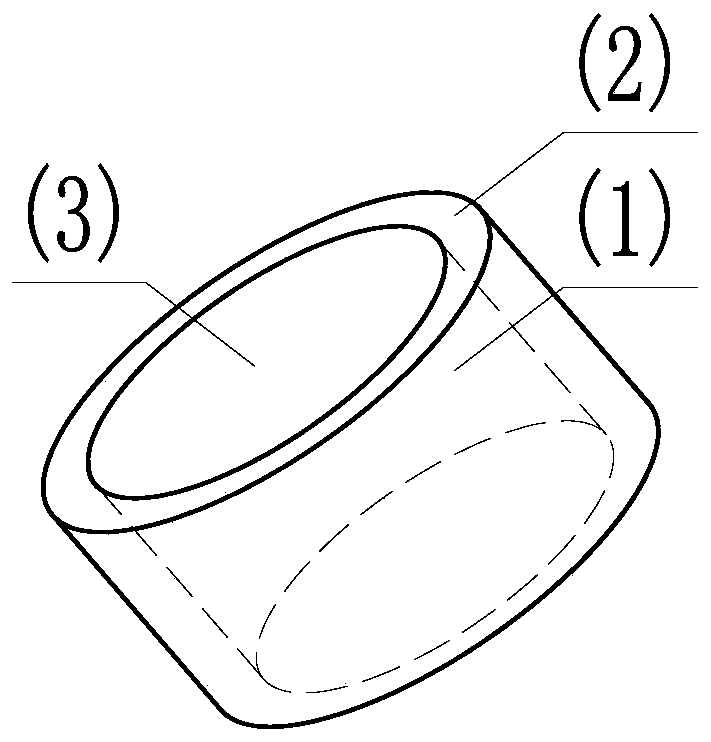

[0027] 2. Preparation of filler (1)

[0028] Utilize 90 ℃ of ...

Embodiment 2

[0034] 1. hydrolytic acidification culture culture preparation (same as example 1)

[0035] 2. the preparation of filler (same as example 1)

[0036] 3. Application of hydrolytic acidification active filler (municipal sewage)

[0037] Add 100 suspension balls prepared in 2. to the hydrolytic acidification reactor with an effective volume of 100L filled with filler (1), and finally form a hydrolytic acidification embedded bioactive filler with a filling rate of 20% and a water temperature of 22 ± 3 °C, HRT= 2h , the pH is 6.8-7.3, the raw water is municipal sewage, the reactor runs continuously 24 hours a day, and the ammonia nitrogen conversion output effect of the reactor is measured every day. The test results of the effluent showed that the release concentration of ammonia nitrogen was stable at about 7.0 mg / L after 13 days of culture recovery, and the organic nitrogen was fully converted and released. The bioactive filler reaction tank was continuously operated for nearl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com