Conductive corrosion-resistant metal bipolar plate for fuel cell, and preparation method thereof

A metal bipolar plate and corrosion-resistant metal technology, which is applied to fuel cell parts, fuel cells, circuits, etc., can solve the problems of incompatibility between corrosion resistance and electrical conductivity, poor electrical conductivity of oxides, etc., and achieve compactness Good performance, low porosity, simple and stable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

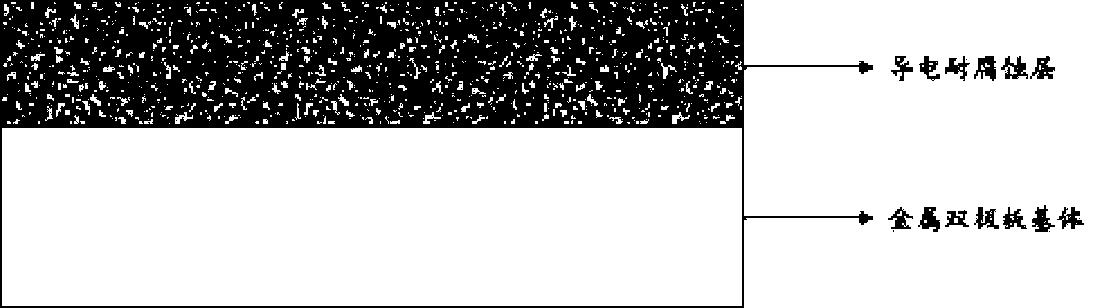

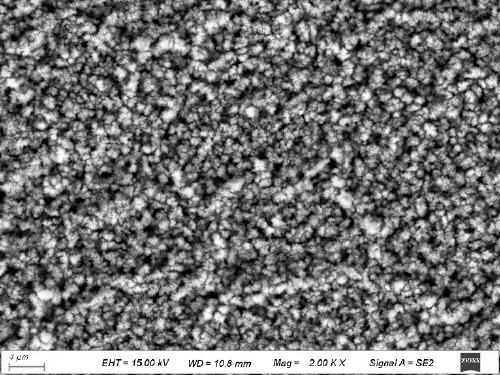

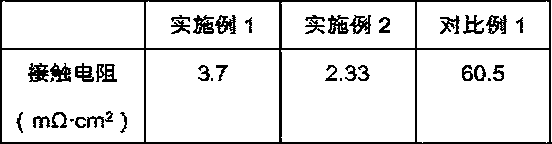

[0024] see figure 1 A conductive and corrosion-resistant metal bipolar plate used for fuel cells is a metal bipolar plate with a surface carburized layer, and the carburized layer is a carburized layer with TiC as the main phase formed on the surface of the metal bipolar plate substrate. The material of the metal bipolar plate substrate is preferably pure titanium, and its thickness is 0.3 mm. The thickness of the carburized layer is 10 μm. The preparation method comprises the following steps:

[0025] (1) Pretreatment of the metal bipolar plate: firstly use sandpaper to polish the surface of the metal bipolar plate, then use a polishing machine to polish, then rinse with distilled water, and then immerse the metal bipolar plate in ethanol and acetone solutions for ultrasonic cleaning 30min, and then dried to obtain a clean metal bipolar plate.

[0026] (2) Put the clean metal bipolar plate after the pretreatment of the step (1) into the vacuum chamber of the glow plasma, v...

Embodiment 2

[0030] see figure 1 A conductive and corrosion-resistant metal bipolar plate used for fuel cells is a metal bipolar plate with a surface carburized layer, and the carburized layer is a carburized layer with TiC as the main phase formed on the surface of the metal bipolar plate substrate. The material of the metal bipolar plate substrate is preferably pure titanium, and its thickness is 0.1 mm. The thickness of the carburized layer is 1 μm. The preparation method comprises the following steps:

[0031] (1) Pretreatment of the metal bipolar plate: firstly use sandpaper to polish the surface of the metal bipolar plate, then use a polishing machine to polish, then rinse with distilled water, and then immerse the metal bipolar plate in ethanol and acetone solutions for ultrasonic cleaning 30min, and then dried to obtain a clean metal bipolar plate.

[0032] (2) Put the clean metal bipolar plate after the pretreatment of the step (1) into the vacuum chamber of the glow plasma, va...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com