Large-diameter long-pipe-segment circulating water pipeline crossing construction method

A construction method and technology of circulating water pipes, which are applied in the directions of pipe laying and maintenance, pipes/pipe joints/pipes, mechanical equipment, etc., can solve the problems of difficult construction, high construction cost, increase construction cost, etc., and improve construction safety. , The effect of reducing the difficulty of lifting and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0036] The large-diameter and long-section circulating water pipeline piercing construction method of the present invention includes

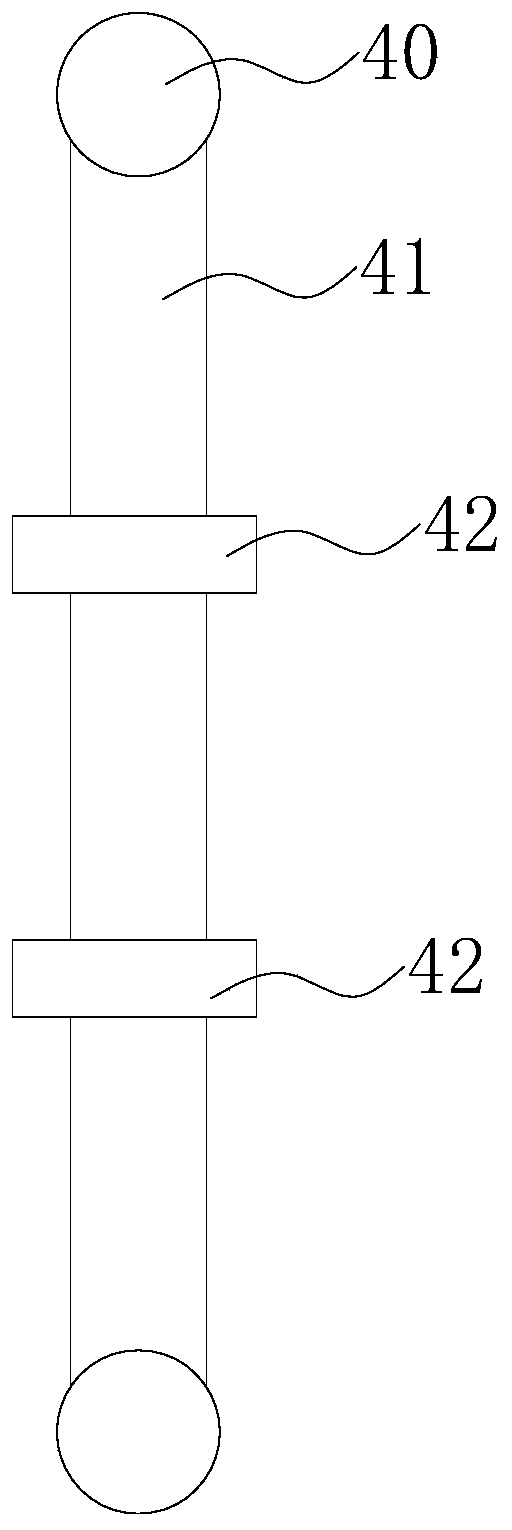

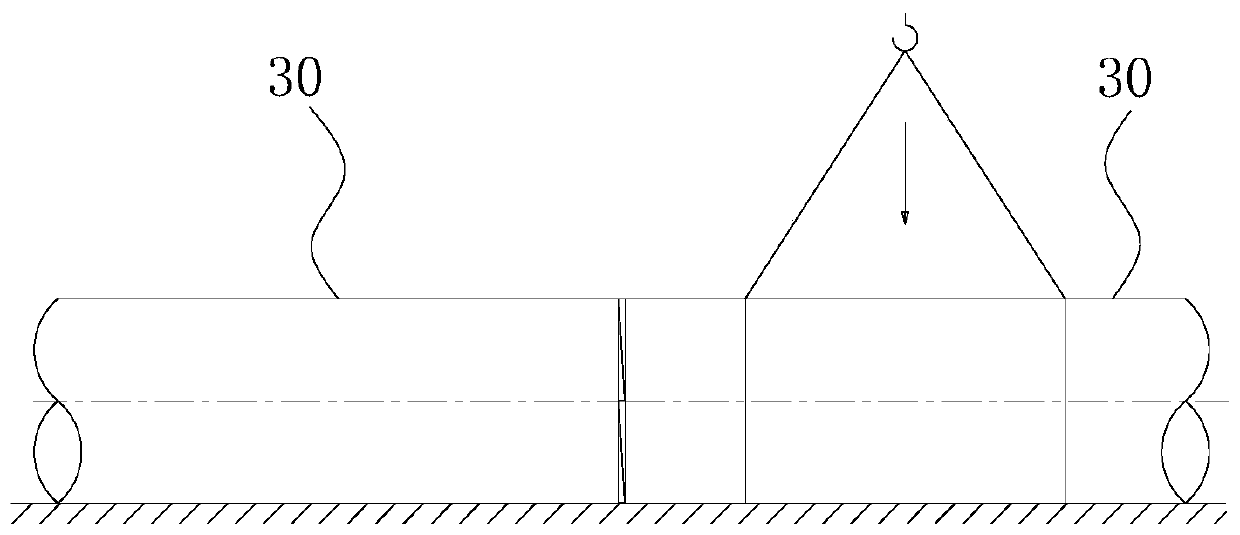

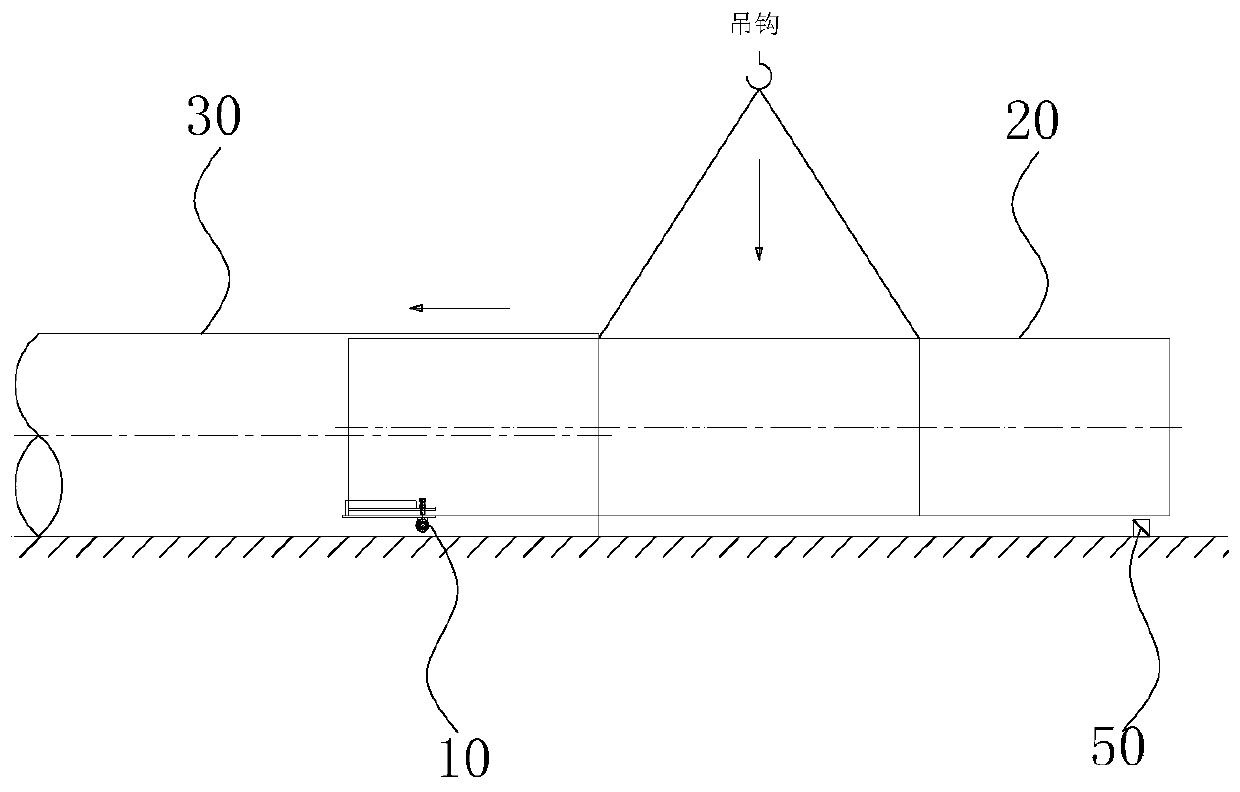

[0037] A. According to the distance between two adjacent inspection wells 40, the raw material of the circulating water pipeline is cut to obtain the multi-section circulating water pipeline 20 . According to the distance between two adjacent inspection wells 40, the raw material of the steel outer casing is cut to obtain a multi-section steel outer casing 30 . Cutting is carried out on the ground, and after the cutting is completed, weld grooves are processed at the ends of the sub-circulation water pipeline 20 and the sub-steel outer casing 30. The distance between two adjacent inspection wells 40 is relatively long. If the circulating water pipeline and the steel outer casing adopt a single integral pipeline, the len...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com