Heating steam driven liquid hydrogen preparation system based on energy gradient utilization

A steam-driven and preparation system technology, which is applied to steam engine devices, household refrigeration devices, lighting and heating equipment, etc., can solve the problems of non-cascade utilization and waste of steam energy, and achieve the goal of improving comprehensive energy utilization efficiency and reducing operating costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the examples. The description of the following examples is provided only to aid the understanding of the present invention. It should be pointed out that for those skilled in the art, without departing from the principle of the present invention, some improvements and modifications can be made to the present invention, and these improvements and modifications also fall within the protection scope of the claims of the present invention.

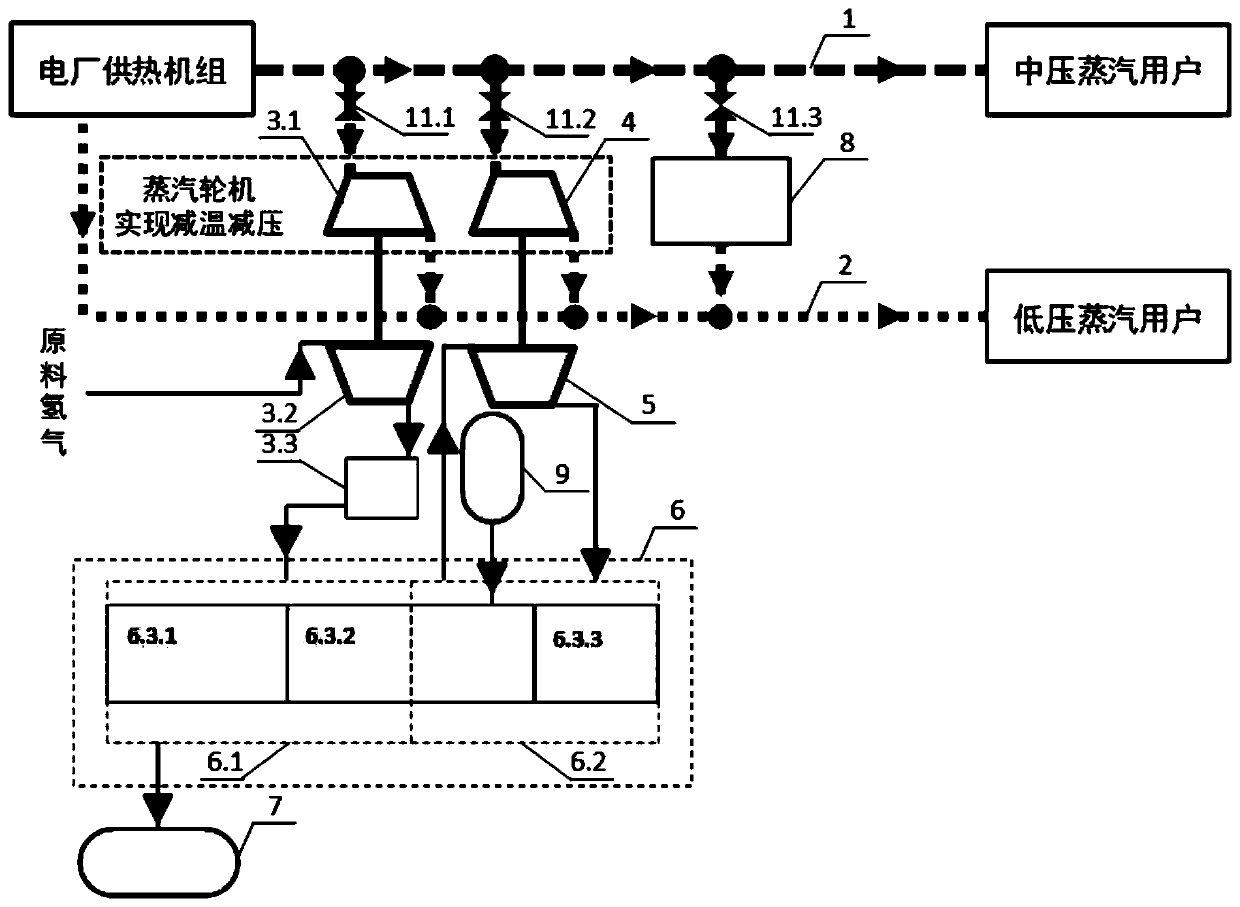

[0024] The heat-supply steam-driven liquid hydrogen preparation system based on energy cascade utilization includes power plant heat-supply medium-pressure steam 1, power plant heat-supply low-pressure steam 2, steam turbine 3.1 for hydrogen purification, compressor 3.2 for hydrogen purification, and hydrogen purification equipment 3.3 , steam turbine 4 for hydrogen liquefaction, compressor 5 for hydrogen liquefaction, cold box 6, liquid hydrogen tank 7, temperatu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap