Rock mass tunnel pipe roof structure and construction method thereof

A construction method and technology of tunnel pipes, which are applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems such as insufficient stability of the grouting structure of tunnel pipe sheds, and achieve remarkable results in controlling ground settlement and inhibiting surrounding rock loosening and collapse Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

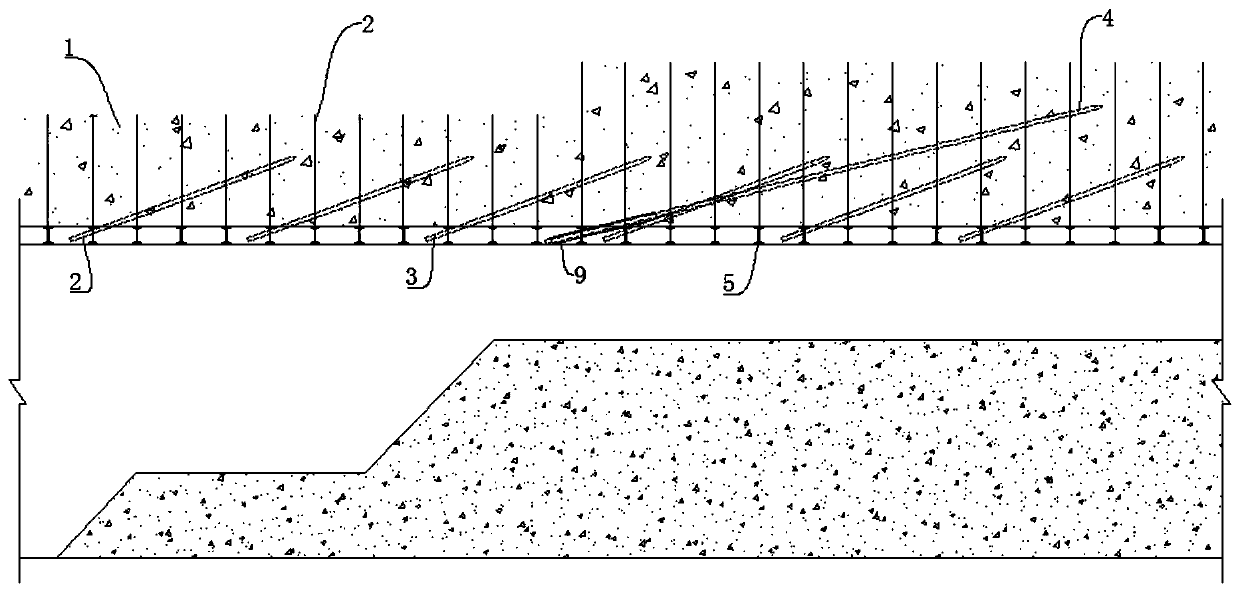

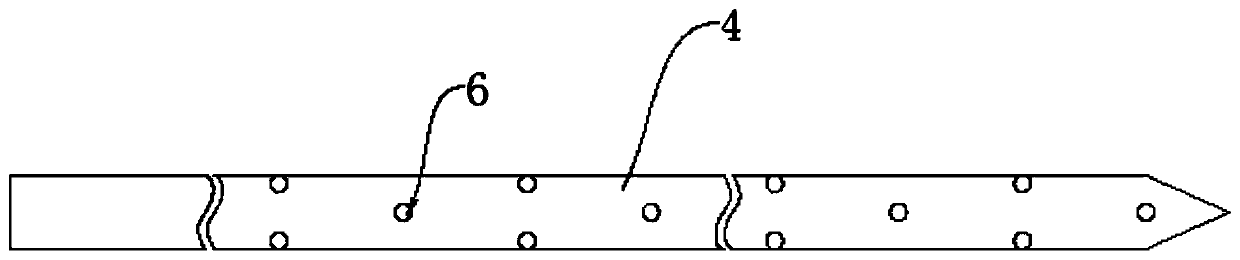

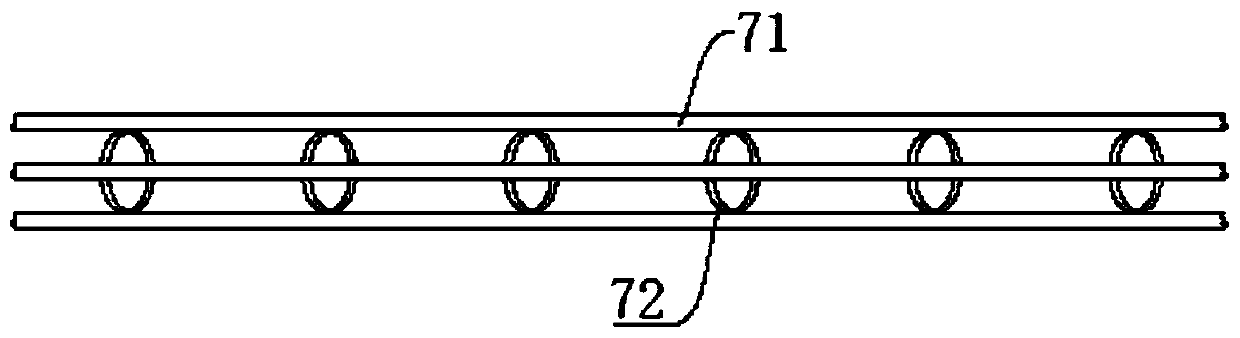

[0033] Such as figure 1 As shown, a rock tunnel tube roof structure includes a rock mass 1, a small radial tube 2, a leading small tube 3, and a tube roof tube 4. A tunnel is excavated on the rock mass 1, and the tunnel is provided with arched side walls , The tunnel is supported by a steel arch 5, which includes a supporting arch and a connecting beam. Several supporting arches are arranged side by side in the tunnel front and rear. There are a number of connecting beams between two adjacent supporting arches. The connecting beams on both sides are staggered, and the steel arch frame 5 plays a role of preliminary support to the rock mass 1. A connecting structure is provided between the two ends of the supporting arch and the rock mass 1. The connecting structure includes a positioning ring 81 and a locking conduit 82. The positioning ring 81 is welded to the supporting arch. The locking conduit 82 penetrates the positioning ring 81 and is inserted into the rock mass 1. Inside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com