Method for preparing 2,5-furan dicarboxylic acid through electro-catalytic oxidation of 5-hydroxymethylfurfural by hydrotalcite-based layered catalyst

A technology of hydroxymethyl furfural and electrocatalytic oxidation, applied in the fields of chemical materials, energy saving and environmental protection, can solve the problems of harsh reaction conditions, high reaction temperature, high cost, etc. The effect of low potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

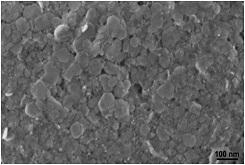

[0033] NiCoFe-LDHs layered catalyst materials were prepared by traditional co-precipitation method. Equipped with 0.5 M Ni respectively 2+ , 0.5 M Co 2+ , 1.0 M Fe 3+ , 1.0 M NaOH and 0.1 M Na 2 CO 3 The solution is stored in a Teflon bottle. When used, take 1.5 mL 0.5 M Ni respectively 2+ , 1.5 mL 0.5 M Co 2+ and 0.75 mL of 1.0 M Fe 3+Place in a 10 mL beaker for ultrasonic mixing for 20 min, then take an appropriate amount of 1.0 M NaOH and 0.1 M Na2CO3 solution (volume ratio 2: 1) and place in another beaker for ultrasonic mixing for 20 min. Then pour the two mixed solutions into the acid-base burette respectively and complete the titration in the four-neck round bottom flask. Before titration, pour 20 mL of ultrapure water into the four-neck flask and put it into a pH meter, and add magnetic stirring at the same time. , the stirring speed increases with the progress of the titration, and the pH at the end of the titration is about 9.5. After the titration was compl...

Embodiment 2

[0037] The NiCoFe-LDHs layered catalyst material prepared in Example 1 was used.

[0038] Electrocatalytic oxygen generation performance test:

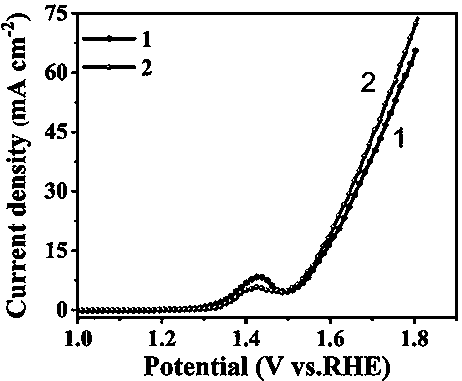

[0039] In order to study the electrocatalytic oxygen production performance of the catalyst material, the Multi Autolab M204 electrochemical workstation was used to test the traditional three-electrode system. The NiCoFe-LDHs nanosheet loaded on the CFP is directly used as the working electrode, the Ag / AgCl electrode is used as the reference electrode, the platinum wire electrode is used as the counter electrode, and the electrolytic cell is a double-chamber cell with a DuPont proton exchange membrane in the middle. The solution was 1 M NaOH and 1 mM 5-hydroxymethylfurfural solution. In order to facilitate the comparison of OER catalytic performance, the reference potential of the test is converted into a reversible hydrogen electrode potential according to the following formula: E RHE =E Ag / AgCl +0.059*pH+E 0 Ag / AgCl . Before t...

Embodiment 3

[0043] Using the NiCoFe-LDHs layered catalyst material prepared in Example 1, at 35°C, the performance test of electrocatalytic oxidation of 1mM 5-hydroxymethylfurfural:

[0044] Using the Multi Autolab M204 electrochemical workstation, the test was carried out through the traditional three-electrode system. The NiCoFe-LDHs nanosheet loaded on the CFP is directly used as the working electrode, the Ag / AgCl electrode is used as the reference electrode, the platinum wire electrode is used as the counter electrode, and the electrolytic cell is a double-chamber cell with a DuPont proton exchange membrane in the middle. The solution was 1 M NaOH and 1 mM 5-hydroxymethylfurfural solution, and the scanning speed was 10 mV s -1 , the scanning range is from 0 to 0.8 V (vs. the reference electrode), and the electrocatalytic oxidation reaction temperature is 35 °C. To facilitate the comparison of OER catalytic performance, the tested reference potential was converted to the reversible hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com