Low-cost bio-based mutual-modified sustained/controlled-release fertilizer easy to biologically/optically degrade and production devices thereof

A double degradation, slow and controlled release fertilizer technology, applied in fertilization devices, spray devices, layered/coated fertilizers, etc., can solve the problems of fast heat dissipation of materials, difficult control of the reaction process, and high production energy consumption. Simple, high-quality production results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

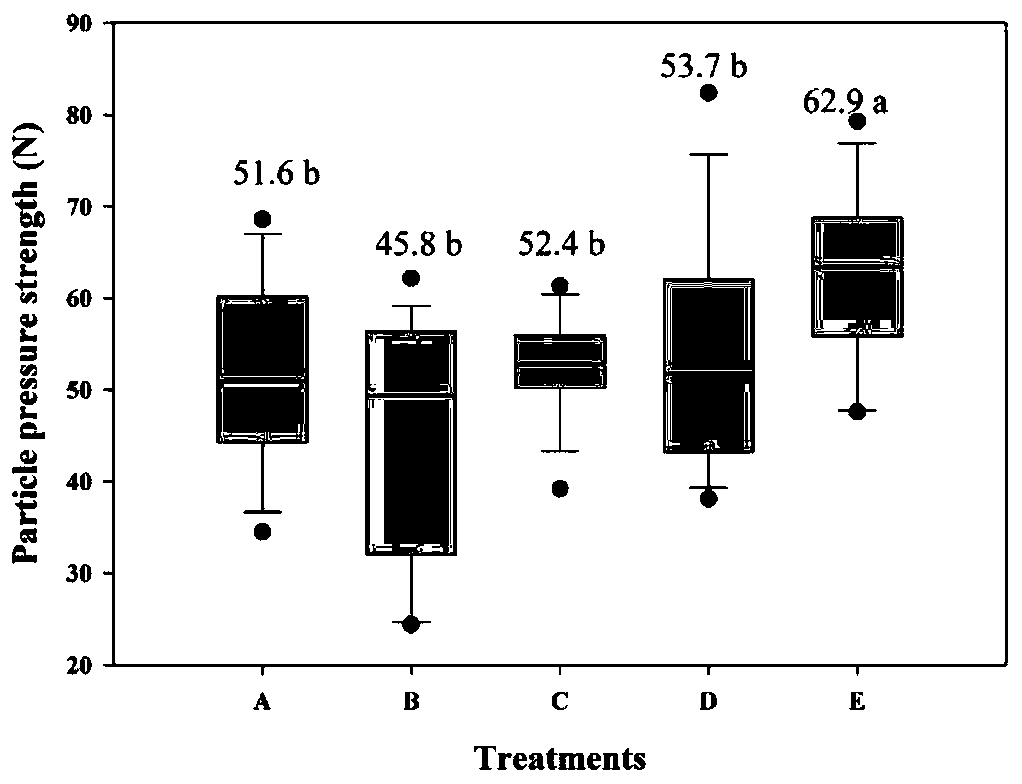

Image

Examples

Embodiment 1

[0081] Example 1: Preparation of controlled-release fertilizer using a low-cost bio-based intermodified slow-release fertilizer production device that is easy to bio / photodegradable

[0082] (1) Grind the rice husk through a 60-mesh sieve, dry for 8 hours, mix the dried rice husk, glycerin, and concentrated sulfuric acid at a ratio of 65:100:9, react at 85°C for about 100 minutes, and cool to room temperature. The plant-derived liquefied product was prepared; maleic anhydride and olive oil were mixed and reacted at 145°C for 120 minutes at a mass ratio of 296:100, and vegetable oil polyol was obtained after cooling; the plant-derived liquefied product and vegetable oil polyol were mixed at a mass ratio of 176: 103 Mix evenly to make bio-based polyol, then mix bio-based polyol, hexamethylene diisocyanate, SnO 2 According to the mass ratio of 1050:1495:2 batching, the coating material is obtained.

[0083] (2) Put 10 kg of urea granules (2-5 mm in diameter) into the barrel thro...

Embodiment 2

[0087] Example 2: Continuous production of controlled-release fertilizers using a continuous production device for low-cost bio-based intermodified slow- and controlled-release fertilizers that are easy to bio / photodegradable

[0088] (1) Grind the wheat straw through a 70-mesh sieve, dry it for 6 hours, mix the baked wheat straw, polyethylene glycol, and hydrochloric acid at a ratio of 150:100:9, react at 150°C for about 112 minutes, cool to room temperature, and prepare Obtain plant-derived liquefaction products; mix methanol and cottonseed oil at 120°C for 90 minutes at a mass ratio of 550:100, and obtain vegetable oil polyols after cooling; mix plant-derived liquefaction products and vegetable oil polyols at a mass ratio of 5:100 evenly , and then mix polyol, hydrogenated phenylmethane diisocyanate, and CdS according to the ratio of 244:65:10 to prepare the coating material.

[0089] (2) Open the metering valve on the feeding pipe, so that the first batch of 200kg compound...

Embodiment 3

[0091] Add 100kg of potassium nitrate granules (diameter 2-4mm) into the production device to preheat the fertilizer to 70°C; spray 1kg of trace element chelating liquid on the surface of the preheated fertilizer granules, and react for about 8 minutes; grind the rice bran Pass through a 90-mesh sieve, dry for 6 hours, mix the dried rice bran, tetrahydrofuran and 1,4-butanediol 1:2 mixture, and phosphoric acid at a ratio of 100:100:2, react at 180°C for about 180 minutes, and cool to room temperature. The plant source liquefaction product was prepared; ethanol, flax oil, and potassium hydroxide were mixed and reacted at 80°C for 75 minutes at a mass ratio of 150:100:13, and vegetable oil polyols were obtained after cooling; the plant source liquefaction products and vegetable oil polyols were prepared according to The mass ratio is 1:1 and mixed evenly to obtain bio-based polyol, then bio-based polyol, diphenylmethane diisocyanate, TiO 2 It is formulated according to the mass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com