Metal organic framework/graphene composite structure and application thereof in identifying gas molecules

A metal-organic framework and graphene composite technology, which is applied in the direction of graphene, single-layer graphene, non-metallic elements, etc., can solve the problems of scarcity of reports on MOF applications and obstacles to applications, and achieve good application prospects, good transparency, and high The effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Example 1: Single-layer graphene is grown on both sides of copper foil by chemical vapor deposition and transferred to a silicon wafer or quartz substrate to epitaxially grow a metal-organic framework structure

[0055] In the first step, in the chemical vapor deposition system, the furnace is heated to 1050 ° C, vacuumed, and then the copper foil is passed through 500 sccm H at high temperature 2 Carry out annealing treatment for 30 min; after the annealing is completed, feed 50 sccm hydrogen and 40 sccm methane to grow single-layer graphene, and cool it out after 30 min;

[0056] In the second step, use O 2 Treat the surface of silicon or quartz substrate with plasma at a power of 50 W for 20 minutes; then react with trichloro(1H,1H,2H,2H-perfluorooctyl)silane (5 μL) for 6 hours in a sealed system at 85°C , so that a self-assembled hydrophobic monolayer film is obtained on the silicon or quartz surface, and then the copper foil is pressed on the silicon wafer or quar...

Embodiment 2

[0058] Example 2: Characterization of Ni-CAT-1 / SLG composite structure obtained by epitaxial growth by transmission electron microscope, scanning electron microscope, atomic force microscope, and grazing incidence small-angle X-ray diffraction

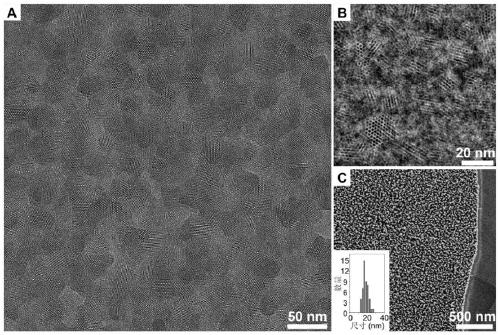

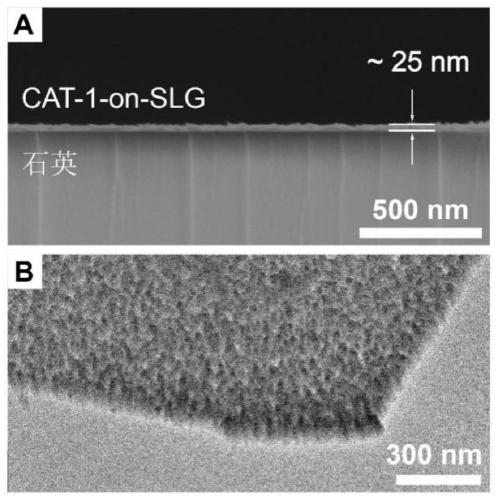

[0059] In the first step, the morphology of the Ni-CAT-1 / SLG composite structure at different thicknesses was characterized by scanning electron microscopy. It can be seen that the graphene surface is uniformly covered by Ni-CAT-1 crystals ( figure 2 (C)); the SEM of the cross-section characterizes the morphology and thickness (25 nm) of the Ni-CAT-1 / SLG composite structure in the cross-section ( image 3 (A));

[0060] In the second step, the Ni-CAT-1 / SLG composite structure was transferred to a TEM copper grid for TEM characterization and analysis; under low magnification, the Ni-CAT-1 crystals were uniformly and densely arranged on the graphene surface ( image 3 (B)), the high-resolution TEM can visually see the one-dimensional c...

Embodiment 3

[0063] Example 3: Using transmission spectroscopy and electrical tests, it is proved that the Ni-CAT-1 / SLG composite structure has good transparency and electrical conductivity

[0064] The first step is to take optical photos of the Ni-CAT-1 / SLG composite structure and graphene at different thicknesses. It can be seen that both the graphene and the composite structure have good transparency ( Figure 7 A); As the thickness of the Ni-CAT-1 / SLG composite structure increases, the transparency gradually decreases;

[0065] In the second step, the transmittance of the Ni-CAT-1 / SLG composite structure and graphene at different thicknesses is quantified by transmission spectroscopy; it can be seen that at 550 nm, the 10 nm Ni-CAT-1 / SLG composite The transmittance of the structure is 95.7%, and as the thickness increases, the transmittance decreases gradually ( Figure 8 );

[0066] The third step is to calculate the conductivity by assembling resistive devices of Ni-CAT-1 / SLG comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com