A CNC lathe with alarm function

A technology of CNC lathes and functions, applied in the field of CNC lathes, can solve the problems of rust, coolant accumulation, and clogging of waste chips of CNC machine tools.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

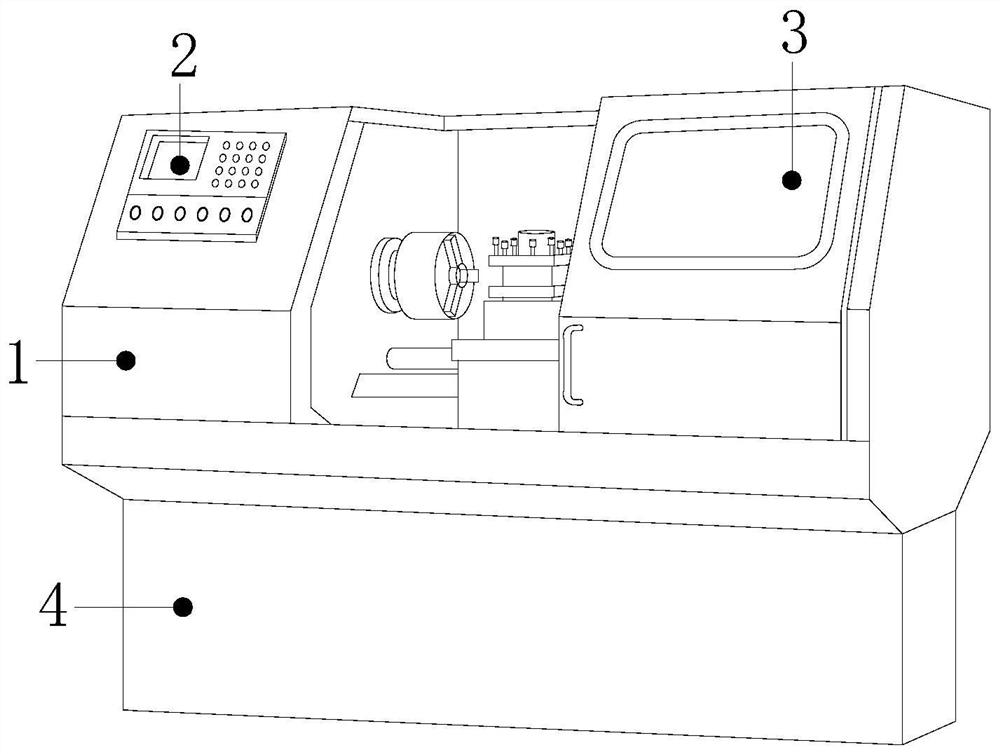

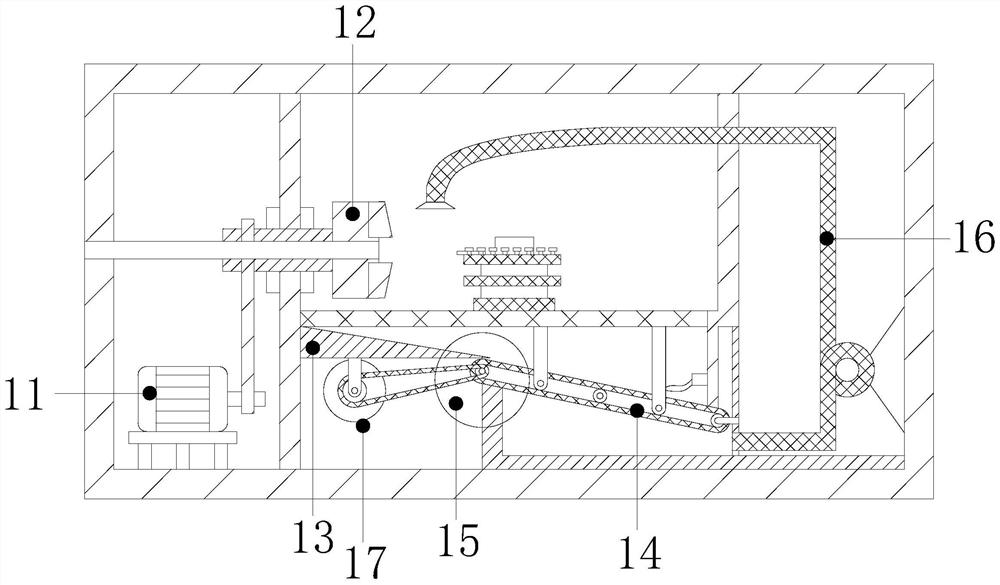

[0026] see Figure 1-Figure 4 :

[0027] A CNC lathe with an alarm function, its structure includes a CNC body 1, a control panel 2, an observation port 3, and a base 4, the CNC body 1 is connected above the base 4 by welding, and the control panel 2 is installed on the CNC body 1 surface, the observation port 3 is embedded in the surface of the CNC body 1, which is characterized in that the CNC body 1 includes a motor 11, a clamp 12, a baffle 13, a material guide belt 14, a separation device 15, a water pipe 16, and a transmission 17. The motor 11 is connected to the inner bottom of the CNC machine body 1 by welding, the clamp 12 is fitted on the top of the motor 11, the baffle plate 13 is embedded in the inner wall of the CNC machine body 1, the material guide belt 14 and the separation device 15 Installed below the baffle plate 13, the water pipe 16 is located inside the CNC machine body 1, the transmission machine 17 is installed on the bottom of the baffle plate 13 and c...

Embodiment 2

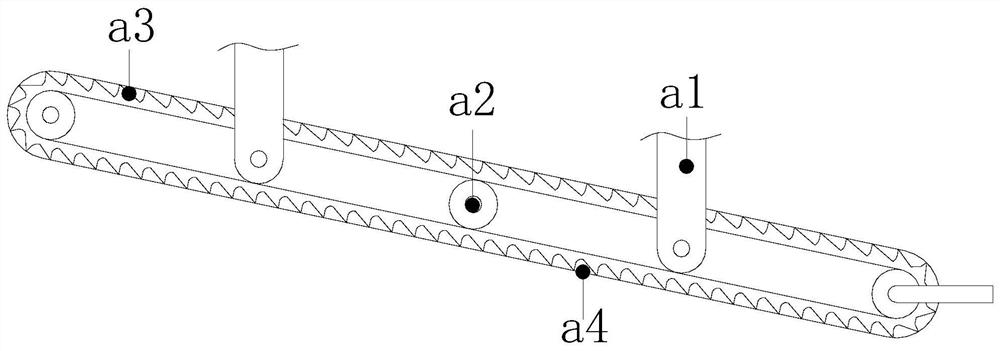

[0032] see Figure 5-Figure 7 :

[0033] In the figure, the separation device 15 includes a conveyor belt b1, a bite groove b2, a drive shaft b3, and a support rod b4. The conveyor belt b1 connects the transmission 17 to the outside of the drive shaft b3, and the bite groove b2 is embedded in the inside of the conveyor belt b1. The support rod b4 is placed directly below the drive shaft b3, and the support rod b4 is connected to the inner bottom of the CNC machine body 1 by welding. The top of the support rod b4 is close to the surface of the isolation belt a3, which is beneficial to the removal of waste in the waste chip chute a4. debris to clean up.

[0034] In the figure, the drive shaft b3 includes a bearing b31, a rotating roller b32, and teeth b33. The rotating roller b32 is embedded and fixed around the bearing b31. The teeth b33 are connected to one side of the rotating roller b32 by welding. There are four teeth b33 and they are arranged around the roller b32. The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com