Intelligent auxiliary dip soldering processing equipment for circuit board

A technology for processing equipment and circuit boards, which is applied in the field of intelligent auxiliary dip soldering processing equipment for circuit boards, can solve problems such as incomplete cleaning of the surface of the solder slurry pool, reduce manual operation steps, improve auxiliary performance, and improve convenience effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

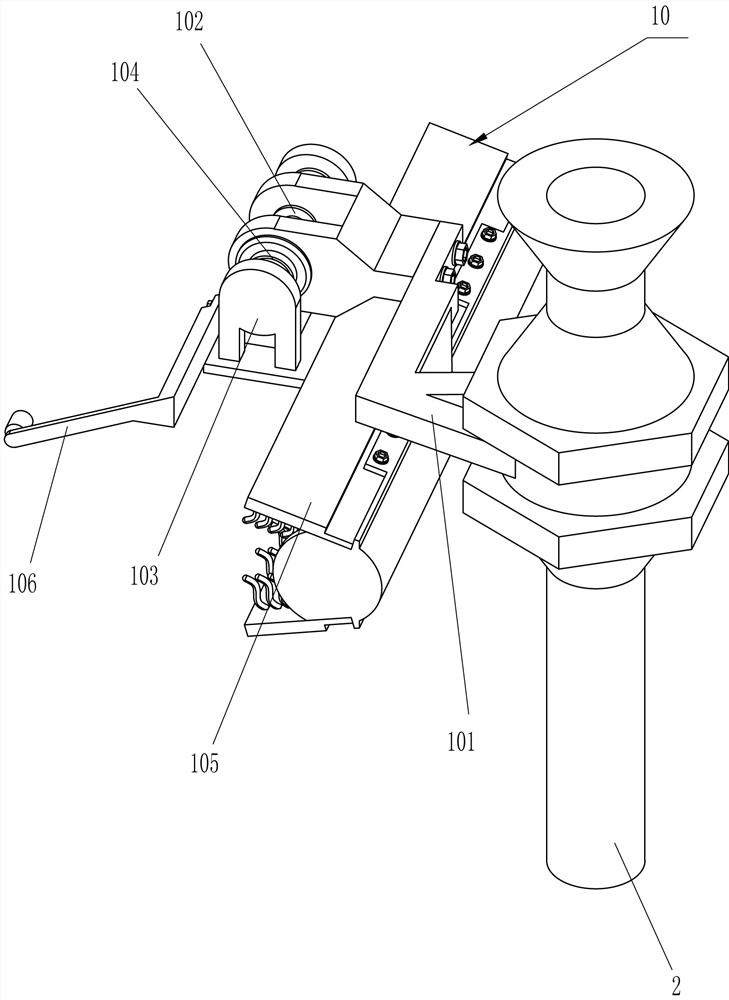

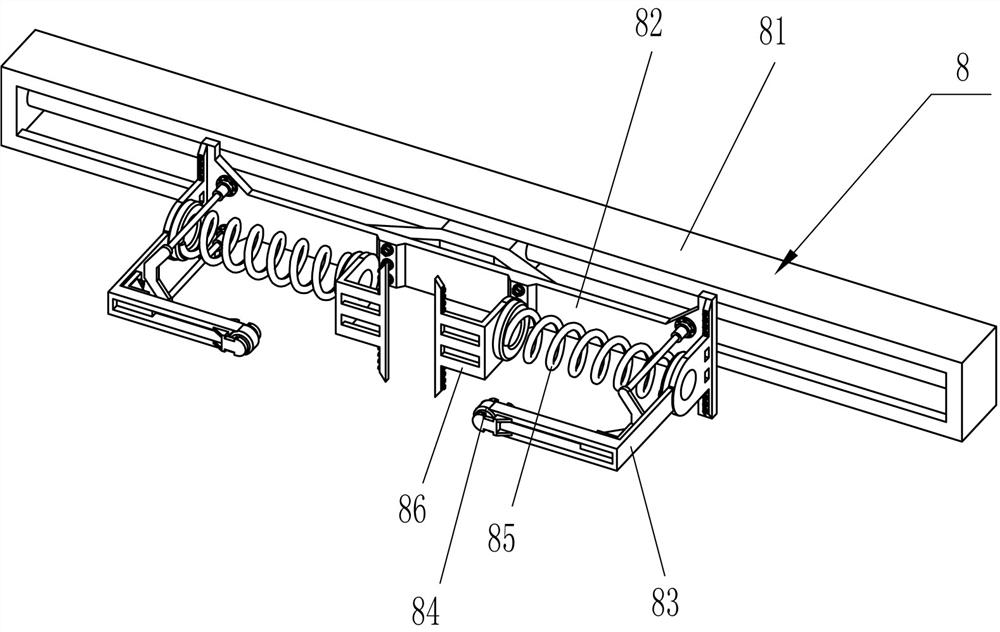

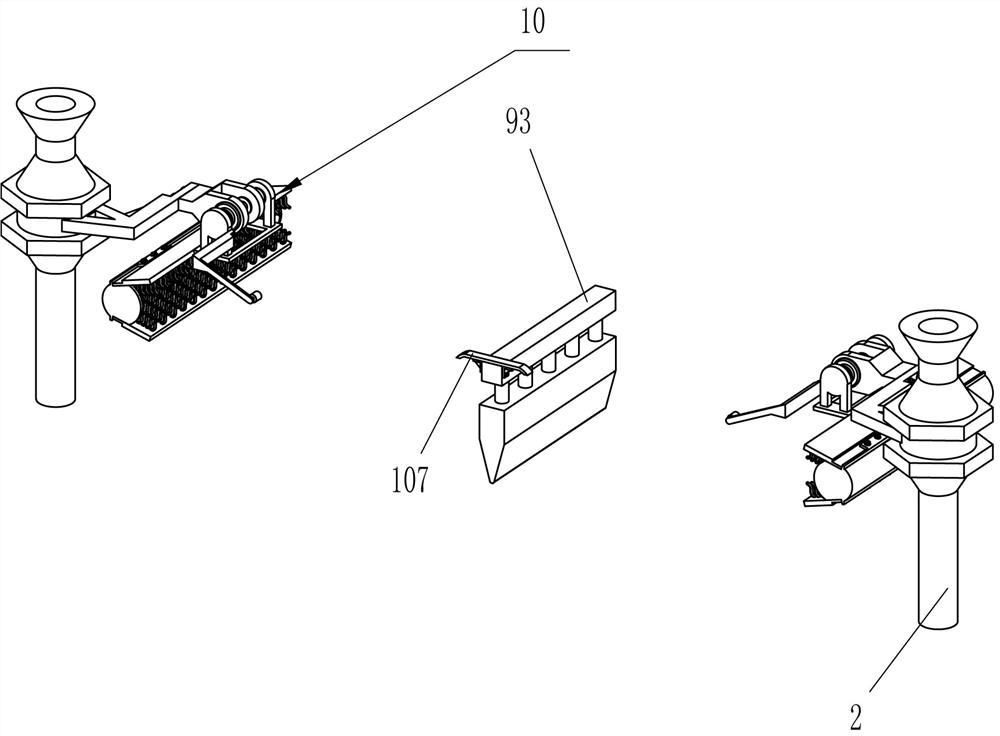

[0033] like Figure 1-5 As shown, an intelligent auxiliary dip soldering processing equipment for circuit boards includes a base 1, a heating chamber 1001 is installed on the upper side of the base 1, and support rods 2 are connected to the left and right sides in front of the upper side of the base 1 by bolts, The upper side of the support rod 2 is connected with the support frame 3 by bolts, the upper side of the support frame 3 is connected with the top frame 4 by bolts, and the bottom of the rear side of the top frame 4 and the rear of the upper side of the base 1 are connected with a fixed rod 5 by bolts. A mounting frame 6 is connected between the fixing rods 5 by bolts. A displacement device 7 is arranged on the front side of the mounting frame 6. The displacement device 7 is used for left and right movement and up and down movement. Connected with the displacement device 7, the propulsion device 8 is used for left and right propulsion, the up and down moving part of th...

Embodiment 2

[0036] like Image 6 As shown, the displacement device 7 includes a first moving pair 71, the upper and lower sides of the front side of the mounting frame 6 are connected with a first moving pair 71 by bolts, and a moving plate 72 is connected between the moving parts of the first moving pair 71 by bolts, The moving plate 72 is connected with the propulsion device 8 , the front side of the moving plate 72 is connected with a second moving pair 73 through bolts, the sweeping device 9 is connected with the moving part of the second moving pair 73 , and the second moving pair 73 is provided with a first elastic member 74, the first elastic member 74 is a straight spring.

[0037] During the operation of the above embodiment, when the propulsion device 8 moves left and right, the propulsion device 8 will drive the moving plate 72 to move left and right through the first moving pair 71, thereby driving the sweeping device 9 to move left and right, and the sweeping device 9 is abou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com