Textile fabric drying equipment for spinning

A technology for drying equipment and textile fabrics, which is applied in the direction of textile material equipment configuration, textile material processing, textiles and papermaking, etc., and can solve problems such as textile fabrics for a long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

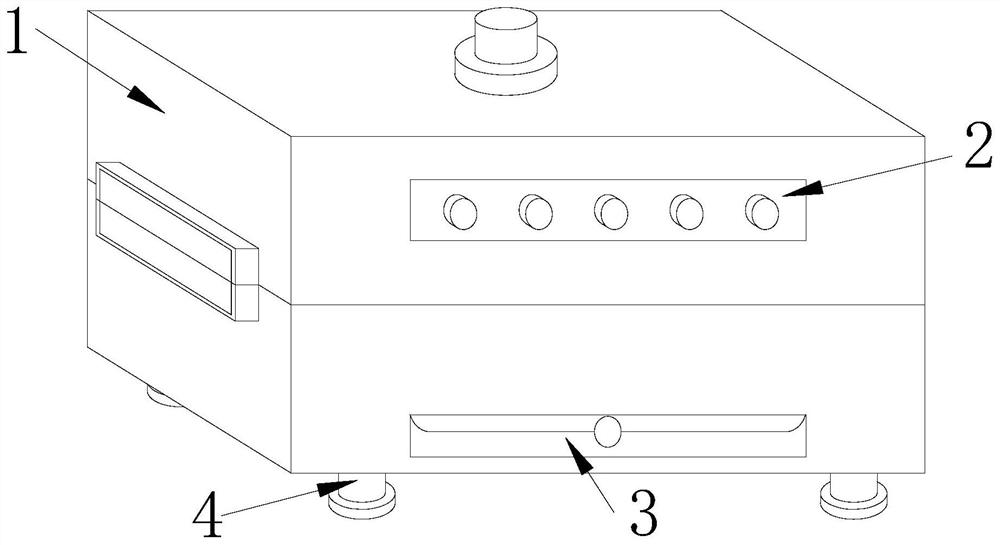

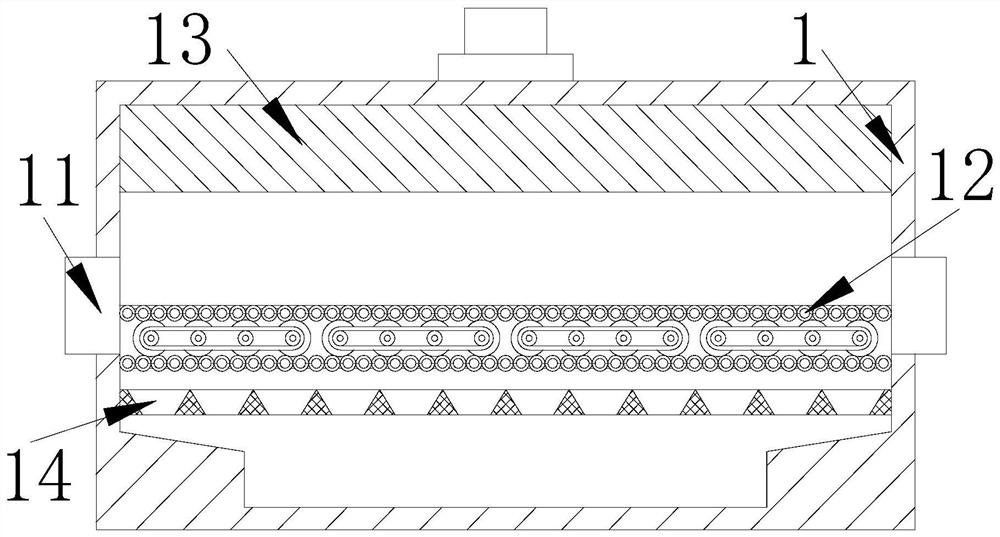

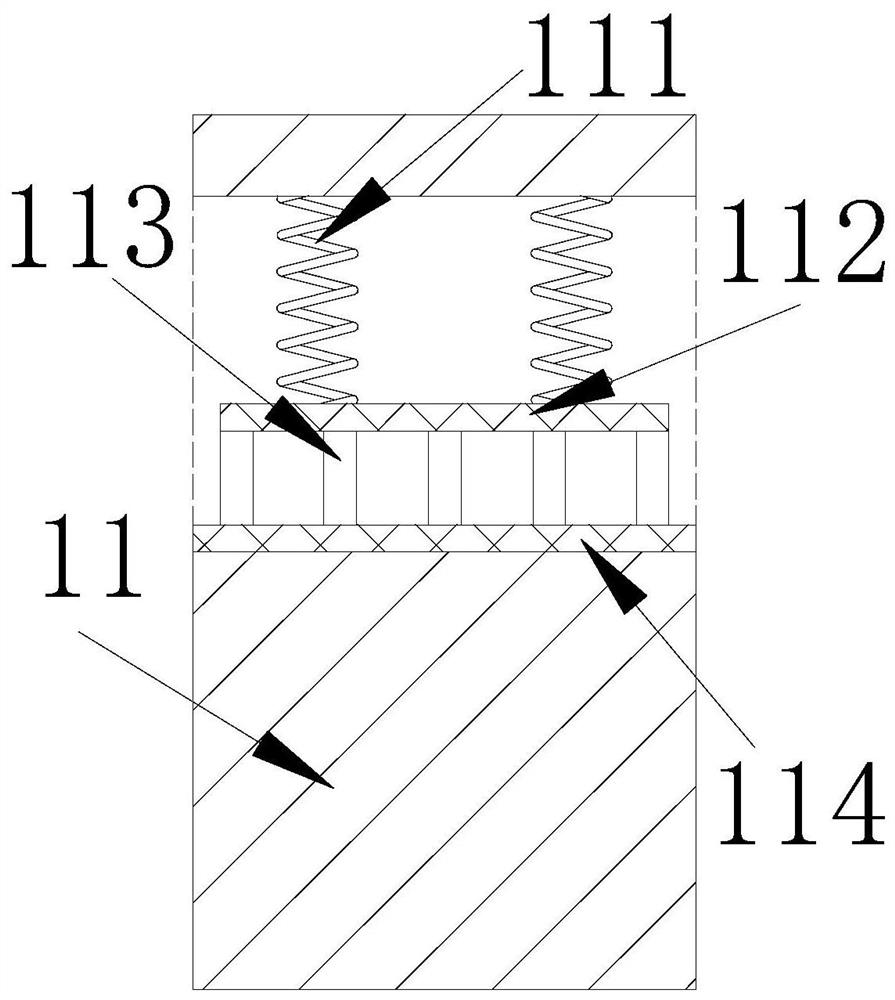

[0029] The present invention provides a textile cloth drying equipment for textile use, the structure of which comprises a drying box 1, a control panel 2, a cleaning tank 3, and a support foot 4, the control panel 2 is embedded in the front side of the drying box 1, and the The cleaning tank 3 is connected to the front side of the drying box 1 through movable engagement, and the supporting feet 4 are connected to the bottom of the drying box 1 by welding. 13. The heating sheet 14, the feed plate 11 is fixed on the left and right sides of the drying box 1, the guide belt 12 is connected to the interior of the drying box 1 by bolts and is located between the two feed plates 11, the The deflector 13 is connected to the top of the drying box 1 by welding, and the outer periphery of the heating sheet 14 is embedded in the inner wall of the drying box 1 and is located directly below the guide belt 12. There are two material-passing plates 11, and the guide belt The upper surface of...

Embodiment 2

[0035]The present invention provides a textile cloth drying equipment for textile use, the structure of which comprises a drying box 1, a control panel 2, a cleaning tank 3, and a support foot 4, the control panel 2 is embedded in the front side of the drying box 1, and the The cleaning tank 3 is connected to the front side of the drying box 1 through movable engagement, and the supporting feet 4 are connected to the bottom of the drying box 1 by welding. 13. The heating sheet 14, the feed plate 11 is fixed on the left and right sides of the drying box 1, the guide belt 12 is connected to the interior of the drying box 1 by bolts and is located between the two feed plates 11, the The deflector 13 is connected to the top of the drying box 1 by welding, and the outer periphery of the heating sheet 14 is embedded in the inner wall of the drying box 1 and is located directly below the guide belt 12. There are two material-passing plates 11, and the guide belt The upper surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com