Reduction furnace bell inner wall spraying device, spraying method and reduction furnace

A spraying device and bell jar technology, applied in spraying devices, devices for coating liquid on surfaces, coatings, etc., can solve the problems of easy oxidation of coatings, increase spraying costs, etc., to avoid oxidation, high bonding strength, retention Effects of Intrinsic Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0061] As a preferred embodiment of the present invention, the rotating component 20 includes a rotating mechanism and a driving mechanism, the driving mechanism is used to drive the rotating mechanism to rotate, and the rotating mechanism is connected to the flange on the bell housing 10 .

[0062] Wherein, the driving mechanism may include a driving motor, the power output shaft of the driving motor is provided with a protrusion, and the rotating mechanism includes a gear plate, and the gear plate is provided with a groove matching the protrusion. After the drive motor is started, the power output shaft rotates to drive the gear plate to rotate, and the gear plate is connected with the flange plate bolts on the bell 10 to drive the bell 10 to rotate.

[0063] As an optional embodiment of the present invention, the sealing member 30 includes a rotating part 31 and a stationary part 32, and the rotating part 31 is connected to the stationary part 32;

[0064] The rotating part...

Embodiment 1

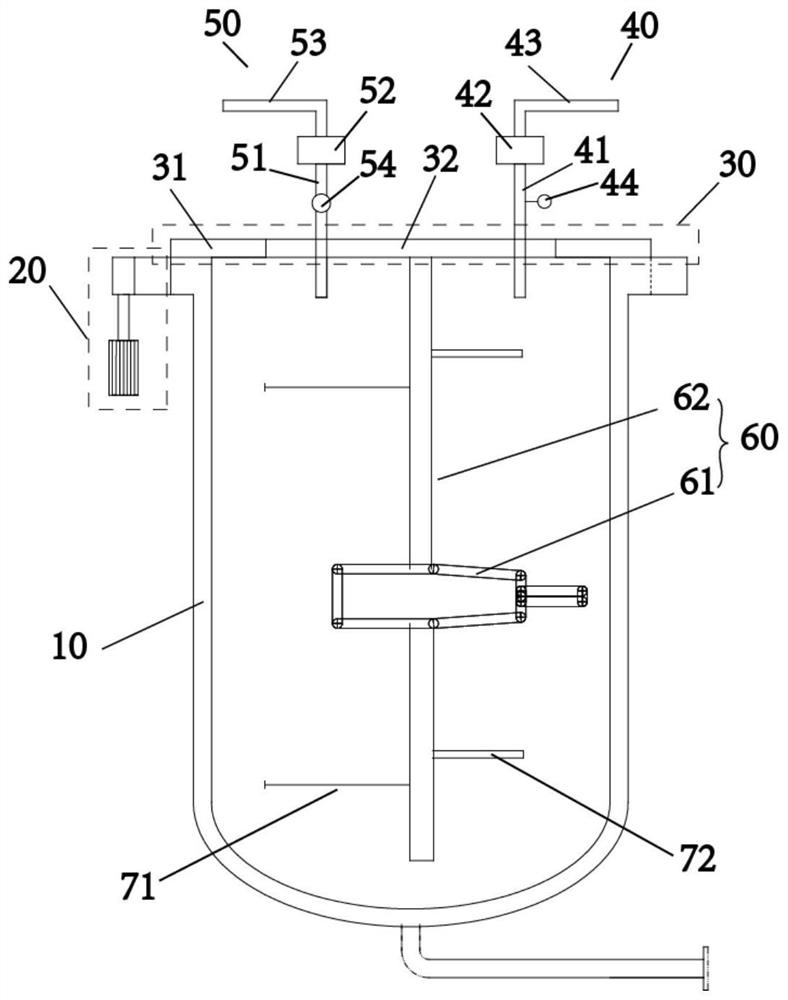

[0100] This embodiment provides a reduction furnace bell inner wall spraying device, specifically as figure 1 As shown, it includes a bell jar 10, a rotating part 20, a sealing part 30, a vacuum part 40, an exhaust part 50, a cold gas power spraying part 60 and a control part (not shown);

[0101] The rotating part 20 is arranged on the outside of the bell jar 10, the sealing part 30 is arranged at the opening of the bell jar 10, the vacuuming part 40 and the exhaust part 50 are all communicated with the inside of the bell jar 10 through the sealing part 30, and the cold gas dynamic spraying part 60 is arranged Inside the bell jar 10 and connected with the sealing member 30, it is used to transport high-temperature protective gas and spray powder into the bell jar 10;

[0102] Wherein, the rotating part 20 includes a driving motor and a gear plate. The power output shaft of the driving motor is provided with a protrusion, and the gear plate is provided with a groove matching w...

Embodiment 2

[0110] This embodiment provides a kind of reduction furnace bell jar inner wall spraying device, except that the nickel matrix layer is arranged on the inner wall of the bell jar 10, the outer surface of the bell jar 10 and the outer surface of the sealing member 30 are respectively provided with an insulating layer ( figure 1 Not shown), the rest of the components and structure are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com