Micro-LED display device, display panel and manufacturing method thereof

A display panel and manufacturing method technology, applied in the direction of instruments, electrical components, electric solid devices, etc., can solve the problems of reduced binding accuracy, small size of Micro-LED chips, errors, etc., to improve the binding accuracy and reduce the arrangement effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

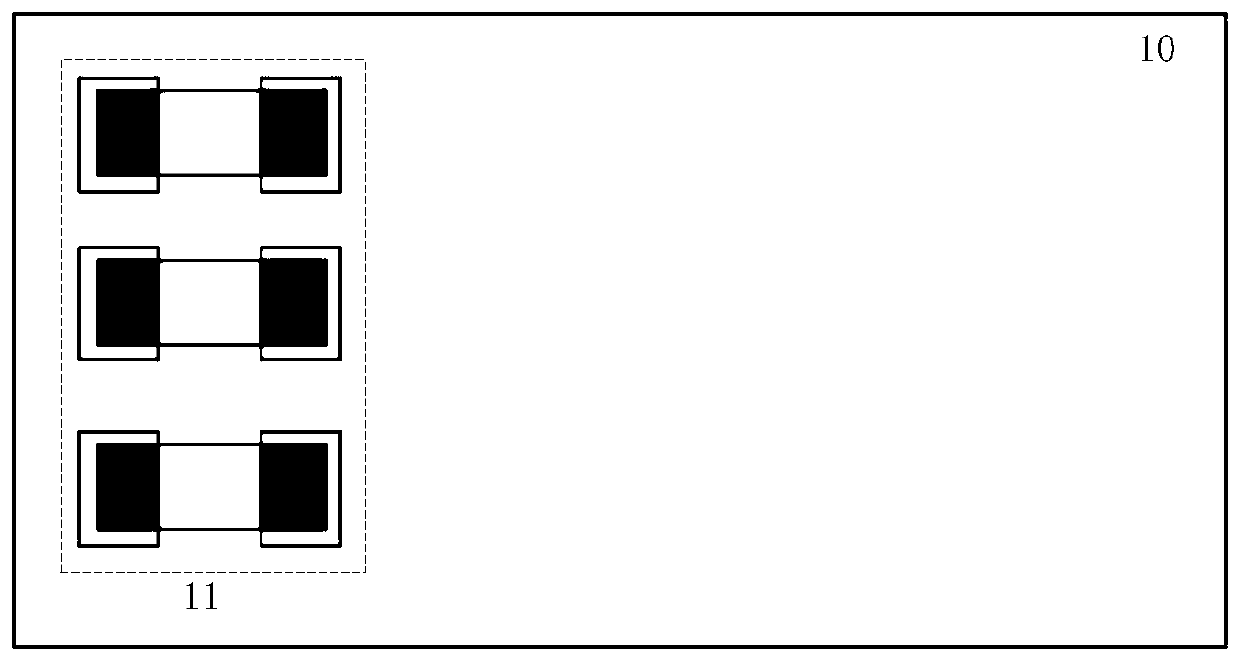

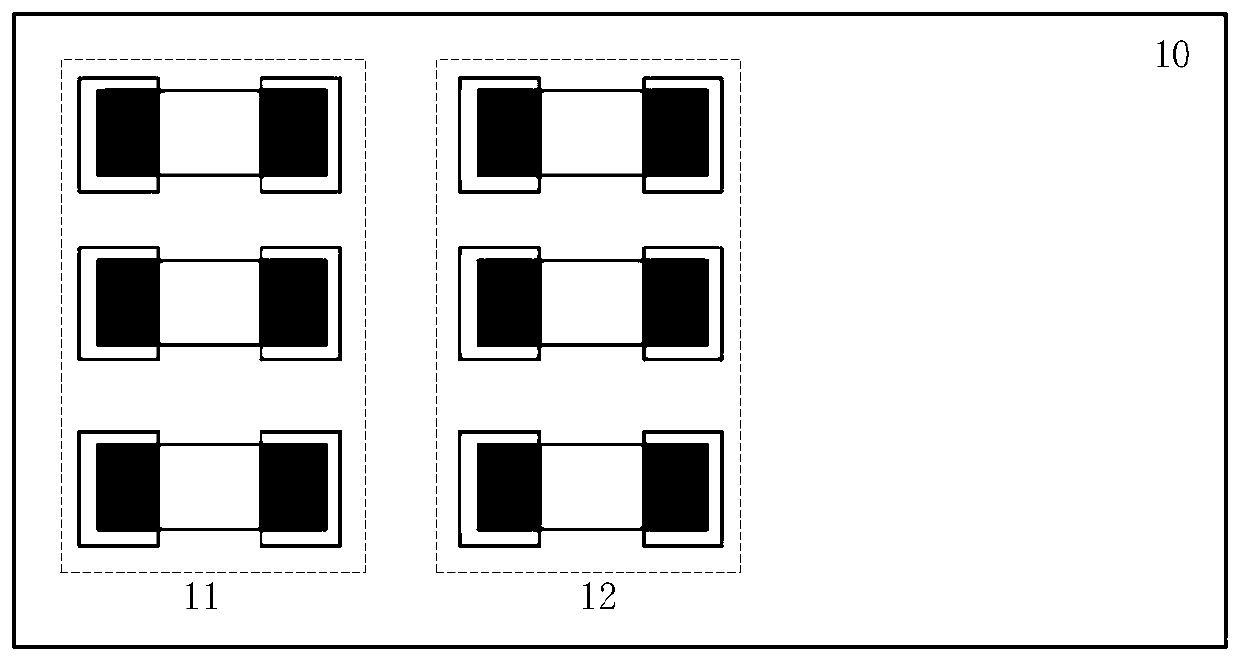

[0038] As mentioned in the background art, the binding accuracy of Micro-LED chips in existing Micro-LED display devices is low. The inventor found that the main reason for this problem is that the metal electrode materials of all Micro-LED chips are the same, so the melting points of the metal electrodes of all Micro-LED chips are the same. The Micro-LED chip is bound to the substrate of the display device in batches. During the subsequent chip binding process, the metal electrodes of the previously bound chip will be heated and dissolved, causing the position of the chip to shift.

[0039] Based on this, in the prior art, only the method of arranging the Micro-LED chips on the temporary substrate in stages, and then using the temporary substrate to transfer all the Micro-LED chips to the substrate of the display device for binding, however, When binding in this way, in the process of arranging the Micro-LED chips according to the colors, there will be errors in the arrangeme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com