Nonlinear cooling optimization method for power battery of new energy automobile

A new energy vehicle and power battery technology, applied in secondary batteries, electrochemical generators, design optimization/simulation, etc., can solve the problems of cooling device damage, energy waste, heat dissipation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0120] The present invention is described in detail below in conjunction with accompanying drawing:

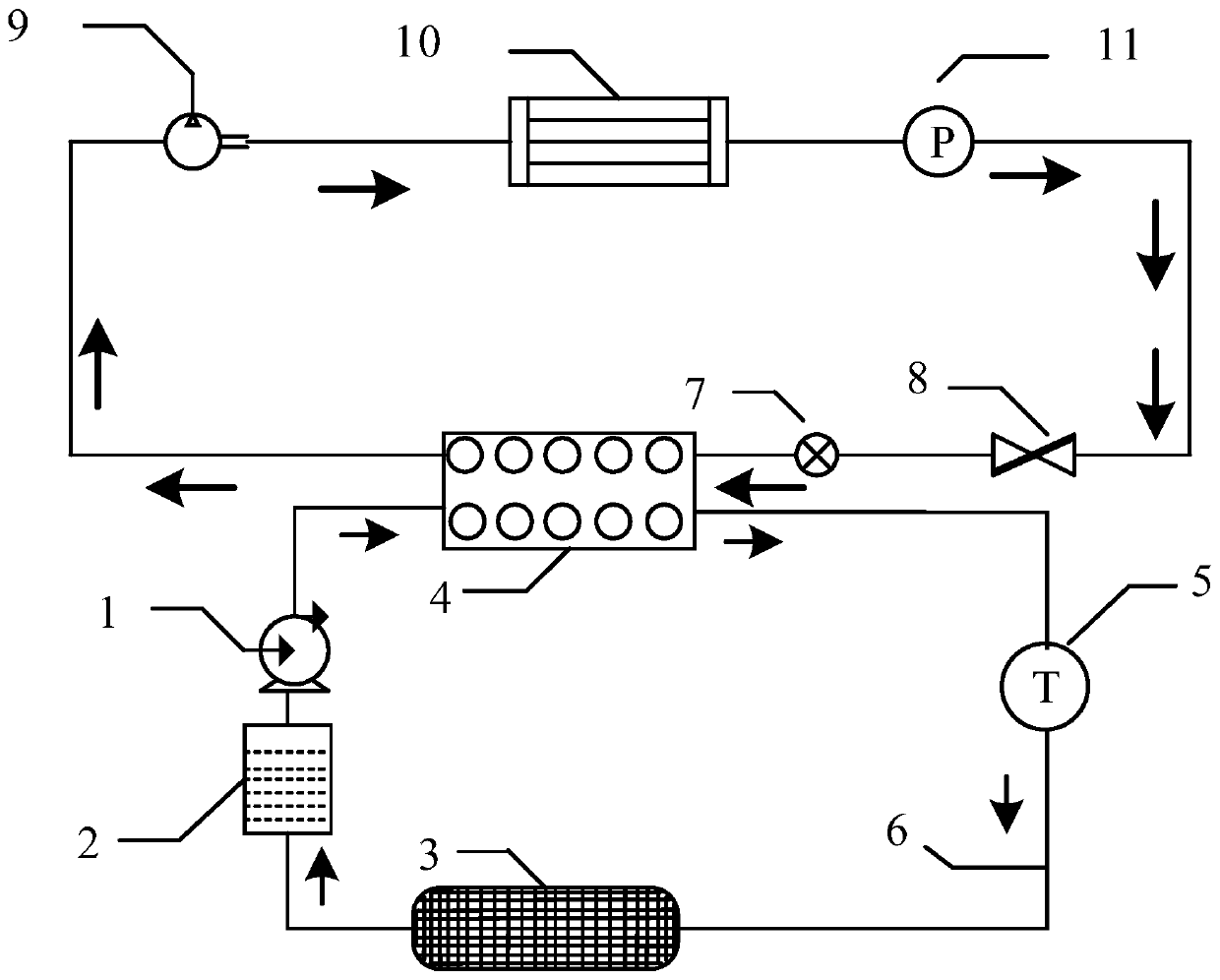

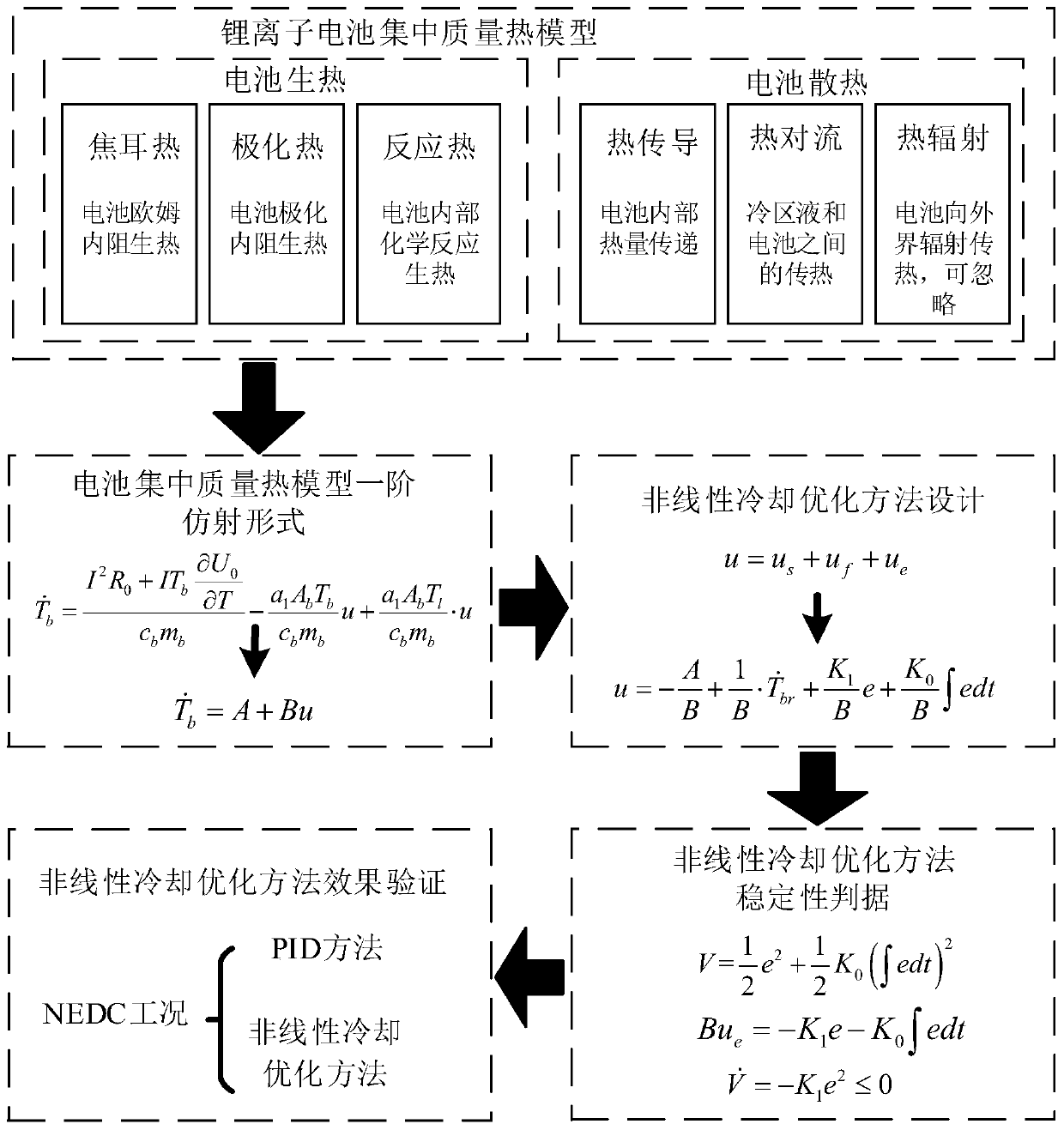

[0121] In the practice of cooling the power battery of new energy vehicles, there are often problems that the response speed of the controller is slow, the temperature cannot be cooled in time, or too much cooling leads to excessive energy consumption. figure 1 This method is based on the new energy vehicle power battery liquid cooling system. Among them, the water pump 1 is used to transport the coolant; the function of the water tank 2 is to store the coolant, and the lithium-ion battery pack 3 composed of multiple lithium-ion batteries is the energy source of the new energy vehicle; the plate heat exchanger 4 cools the coolant; the temperature The sensor 5 measures the temperature of the coolant; the thermal expansion valve 7 throttles the refrigerant; the solenoid valve 8 controls the circulation of the coolant; the compressor 9 discharges the gaseous refrigerant; the cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com