Converter valve TVM plate heating prediction method, system and device and medium

A prediction method and converter valve technology, applied in computer-aided design, design optimization/simulation, calculation, etc., can solve problems such as the difficulty of predicting the heating of TVM boards, and achieve the effect of reducing the risk of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

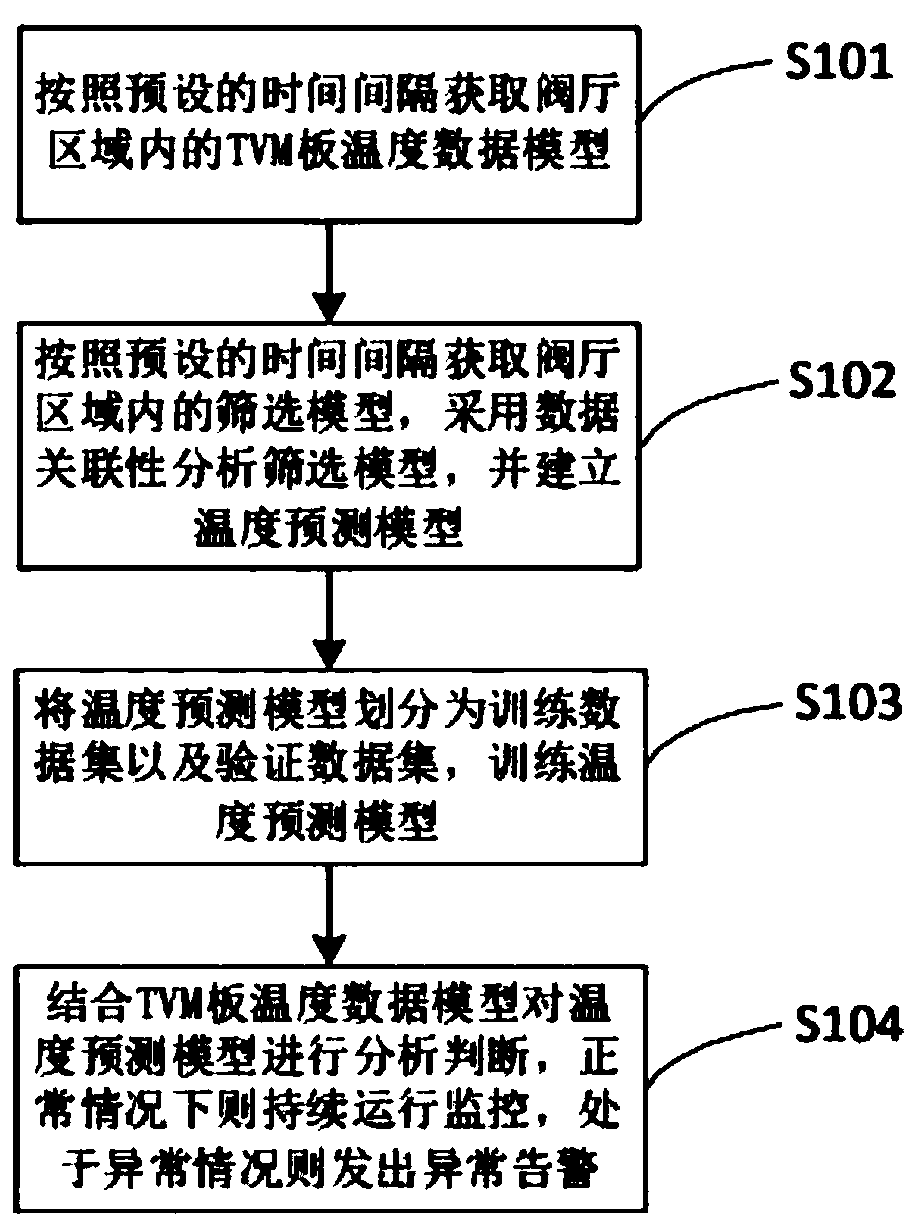

[0044] like figure 1 As shown, this embodiment proposes a method for predicting the heat generation of the TVM board of the converter valve,

[0045] S101. Obtain a TVM panel temperature data model in the valve hall area according to a preset time interval; the TVM panel temperature data model includes TVM panel temperature, valve hall temperature, valve hall humidity, DC power and the average DC power of the previous time interval. The preset time interval is generally 1 hour, but can be adjusted according to actual conditions.

[0046] S102. Obtain the screening model in the valve hall area according to the preset time interval, analyze the screening model by data correlation, and establish a temperature prediction model; the screening model includes TVM board temperature, valve hall temperature, valve hall humidity, DC power and front Average DC power over a time interval.

[0047] S103, divide the temperature prediction model into a training data set and a verification d...

Embodiment 2

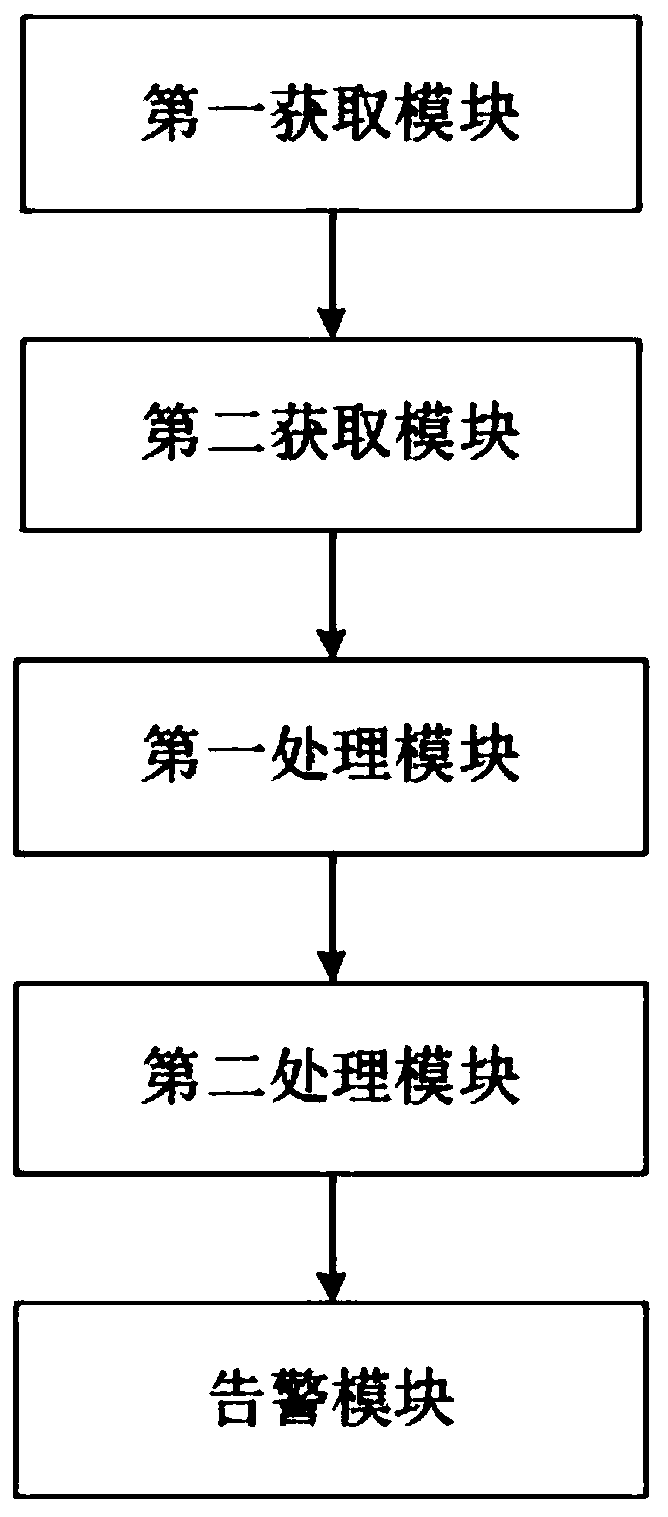

[0077] like figure 2 As shown, this embodiment proposes a heating prediction system for the TVM board of the converter valve,

[0078] The first acquisition module is used to acquire the TVM panel temperature data model in the valve hall area according to the preset time interval;

[0079] The second acquisition module is used to acquire the screening model in the valve hall area according to the preset time interval,

[0080] The first processing module is used to analyze and screen models by data correlation, and establish a temperature prediction model;

[0081] The second processing module is used to divide the temperature prediction model into a training data set and a verification data set, and train the temperature prediction model;

[0082] The alarm module is used to analyze and judge the temperature prediction model in combination with the TVM board temperature data model. Under normal conditions, it will continue to run and monitor, and under abnormal conditions,...

Embodiment 3

[0099] This embodiment proposes a device for predicting heat generation of a converter valve TVM board, the device includes a memory and a processor, wherein,

[0100] The memory is used to store executable program code;

[0101] a processor coupled to the memory;

[0102] The processor invokes the executable program code stored in the memory to execute the method for predicting heat generation of the TVM board of the converter valve described in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com