Minimum pressure valve and compressor including such a minimum pressure valve

A technology of pressure valves and compressors, which is applied in the direction of lift valves, diaphragm valves, valve devices, etc., can solve problems such as high maintenance costs and losses, compressors not running, and affecting the overall performance of minimum pressure valves, etc., to achieve low failure risk, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

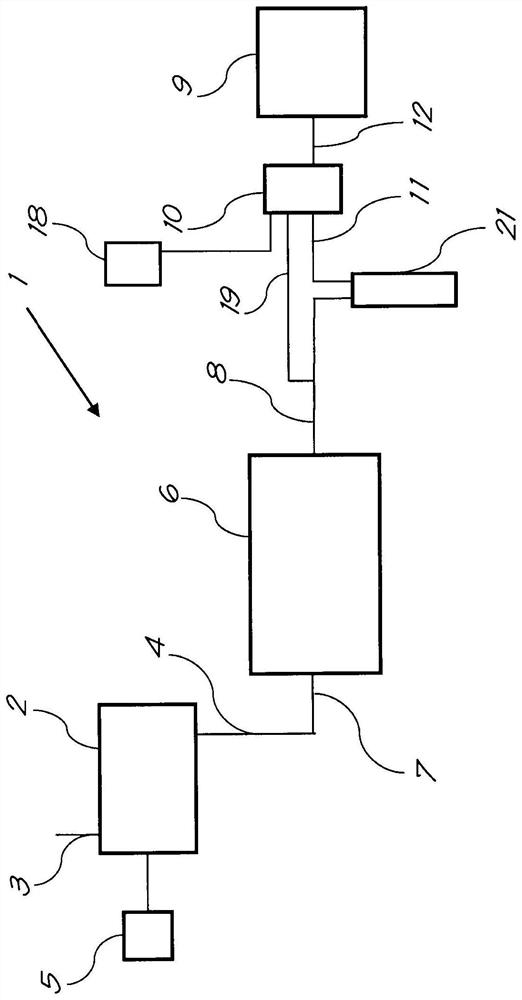

[0029] figure 1 A compressor 1 is shown comprising a compressor element 2 with a gas inlet 3 and a compressed gas outlet 4 . Typically, the compressor 1 is driven by a fixed or variable speed electric motor 5 .

[0030] In the context of the present invention, a compressor 1 is to be understood as a complete compressor device comprising the compressor element 2, all typical connecting pipes and valves, the casing of the compressor 1 and possibly the electric motor driving the compressor element 2 5.

[0031] In the context of the present invention, compressor element 2 is to be understood as a compressor element housing in which the compression process takes place by means of a rotor or by reciprocating motion.

[0032] Furthermore, said compressor element 2 may be selected from the group comprising screws, teeth, claws, scrolls, rotating blades, centrifugals, pistons and the like.

[0033] now refer to figure 1 , the compressor 1 also comprises a pressure vessel 6 having ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com