Discharge lamp and method for producing a discharge lamp

A technology for discharge lamps and discharge capacitors, applied in the manufacture of discharge tubes/lamps, discharge lamps, high-pressure discharge lamps, etc., can solve problems such as failure and lamp damage, and achieve the effect of reducing lamp failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

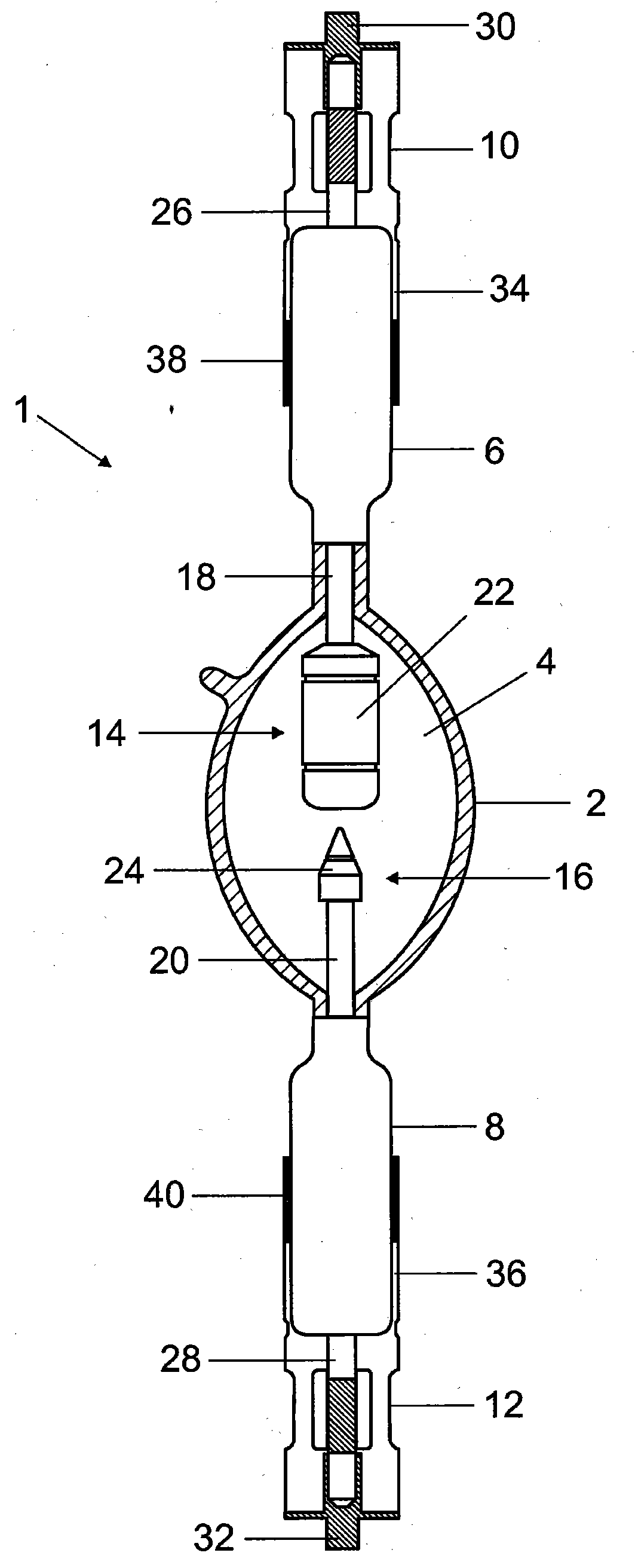

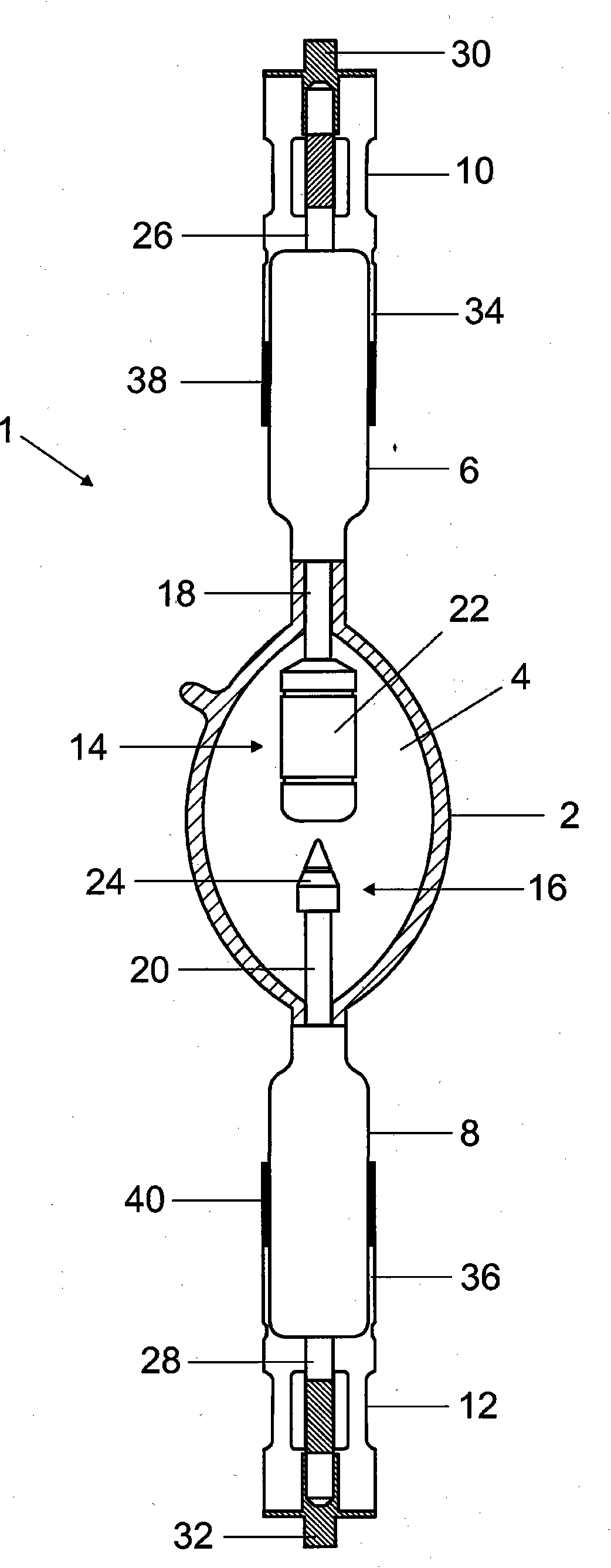

[0018] The invention is explained below on the basis of an exemplary embodiment of a xenon high-pressure discharge lamp 1 . Such lamps contain absolutely no mercury and are therefore particularly environmentally friendly. However, the invention is not limited to xenon lamps but in other lamp types, for example xenon high-pressure discharge lamps, which are suitable for use in mercury-containing lamps, have a very long operating life and produce light that is very similar to natural light. Therefore, this discharge lamp is best used in projectors, stage spotlights and aircraft headlights.

[0019] The so-called "burner" of the discharge lamp 1 has a discharge vessel 2 made of quartz glass, which has an inner cavity 4 and two radially arranged sealed bulb stems 6, 8, on which bulb stems 6, 8 is respectively provided with lamp cover 10,12. The cap sockets 10 , 12 do not have to be—as in the prior art—designed to be elastic. Two electrodes 14 , 16 formed coaxially with one anot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com