In-situ high-temperature spectrum testing device

A spectroscopic testing and high temperature technology, applied in measurement devices, color/spectral characteristic measurement, and electrical devices, etc., can solve the problem that high temperature testing devices cannot take into account spectroscopic testing, gas environment and high pressure, etc., to avoid temperature inhomogeneity , to ensure the effect of temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

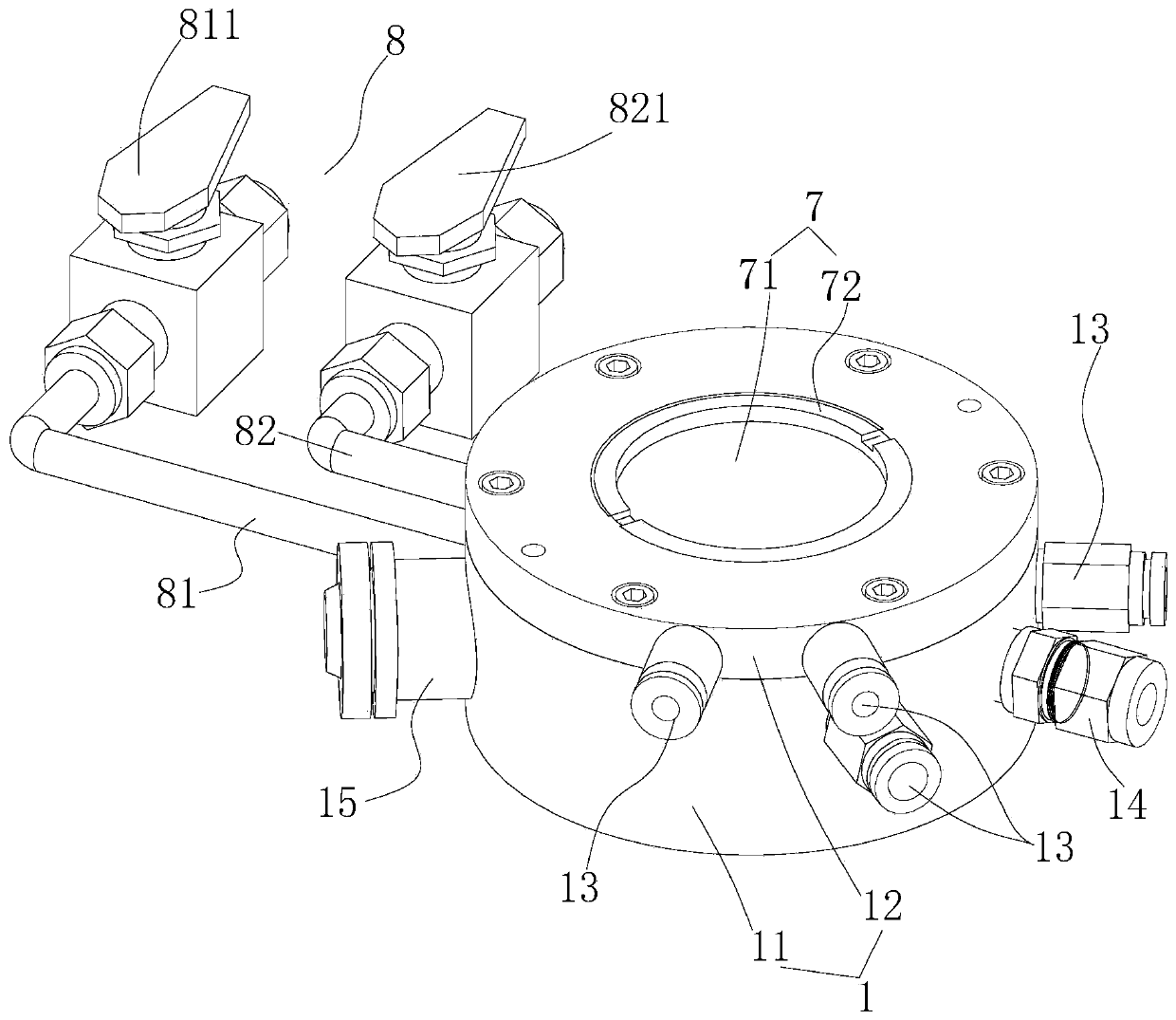

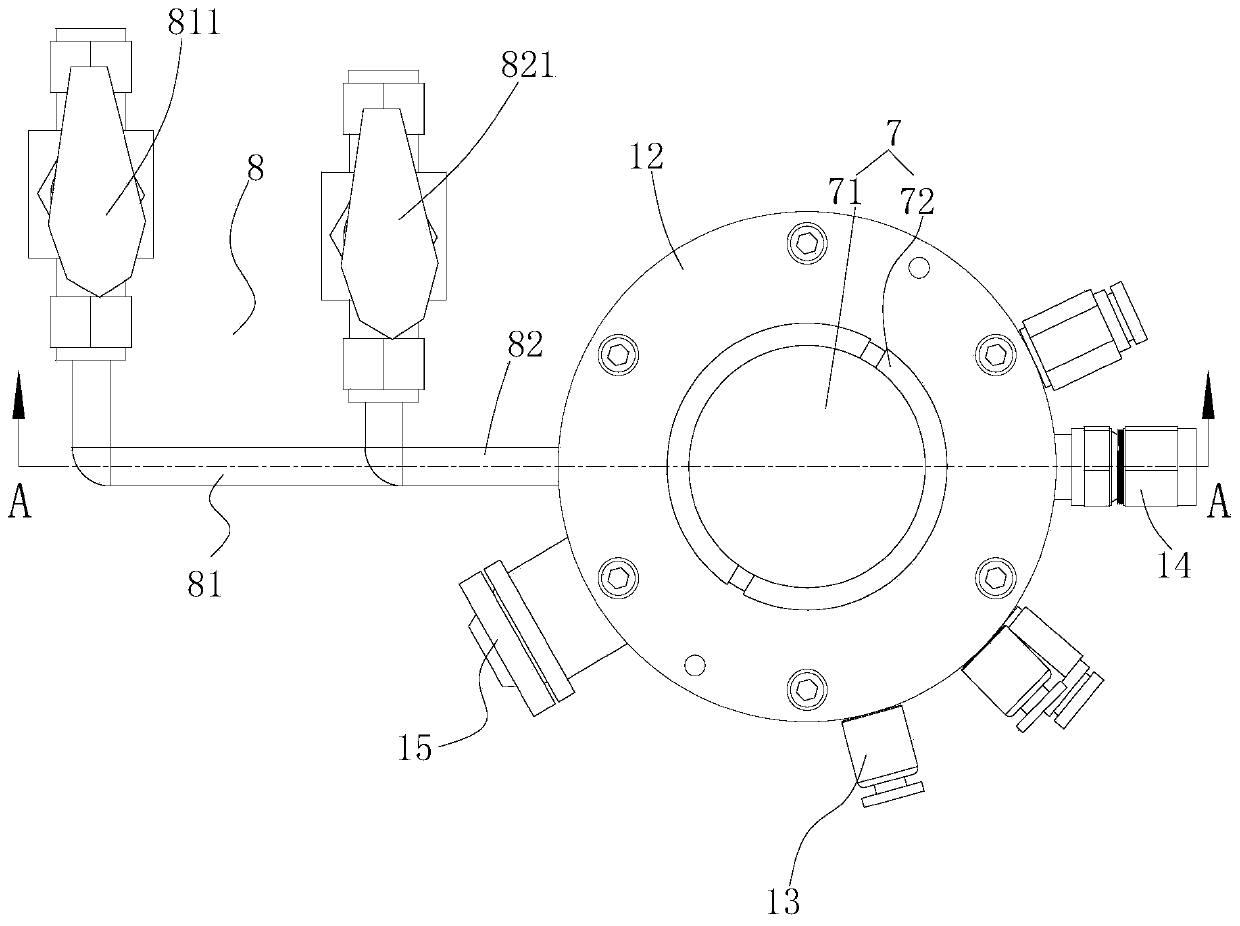

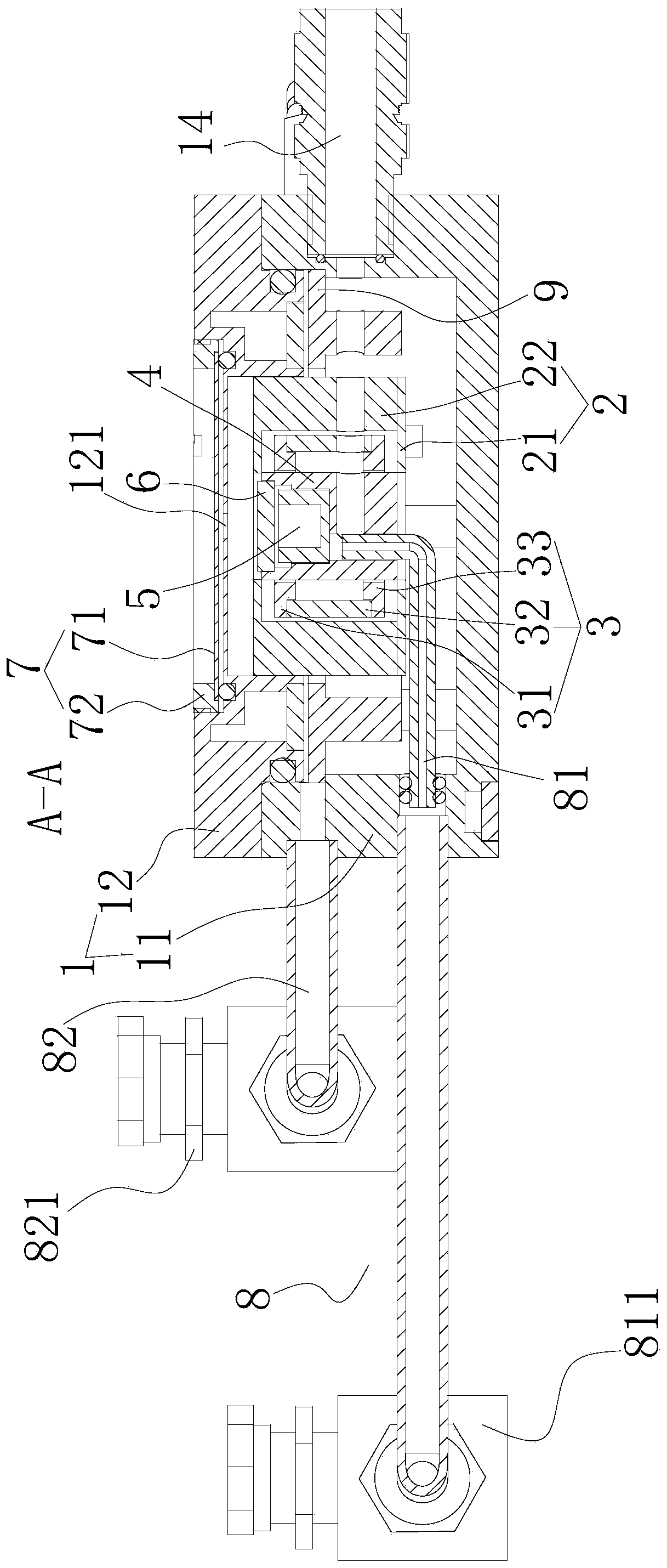

[0057] Such as Figure 1-3 As shown, an in-situ high-temperature spectroscopic testing device includes a housing 1 , a thermal insulation layer 2 , a heating furnace 3 , a sample stage 4 , a sample holder 5 , a sample cover 6 , a window 7 , and a gas system 8 .

[0058] Such as image 3 As shown, a heat insulation layer 2 is arranged in the shell 1, a heating furnace 3 is arranged in the heat insulation layer 2, a sample stage 4 is arranged in the heating furnace 3, a placement groove with an upward opening is provided in the sample stage 4, and a sample holder 5 is arranged in the placement groove, A sample cover 6 is arranged above the sample holder 5 , and a window 7 is arranged on the housing 1 above the sample cover 6 , and external light can pass through the window 7 and enter the sample holder 5 .

[0059] A cooling system is provided in the housing 1 , and a temperature detection device capable of detecting the temperature in the sample rack 5 is also included.

[00...

Embodiment 2

[0072] The difference between this embodiment and Embodiment 1 is:

[0073] Such as image 3 As shown, an annular heat insulation cover 9 is arranged between the lower shell 11 and the heat insulation layer 2, the heat insulation cover 9 is located at the bottom of the upper cover 12, and the bottom of the heat insulation cover 9 is installed on the bottom of the lower shell 9 through arc-shaped support blocks and screws. Shell 11.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com