Mooring cable traction force vector measuring mechanism of mooring unmanned aerial vehicle

A technology of pulling force and measuring mechanism, applied in force/torque/work measuring instruments, measuring devices, instruments, etc., can solve problems such as wind resistance and crash accidents of UAVs that affect the function of mounting and use, and improve the anti-aircraft performance. The effect of wind performance and work reliability, improving flight altitude and ensuring flight safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below with reference to the accompanying drawings and examples.

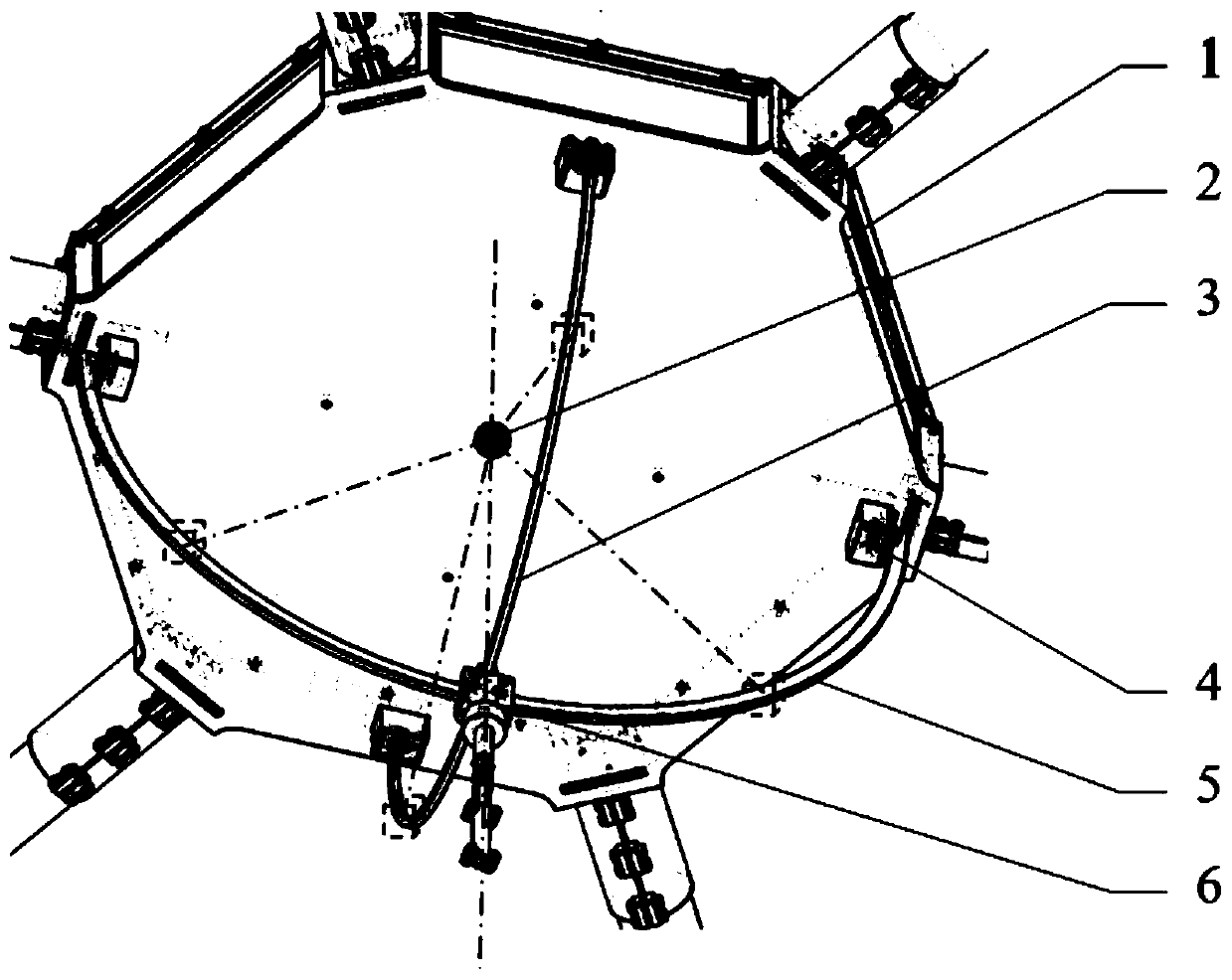

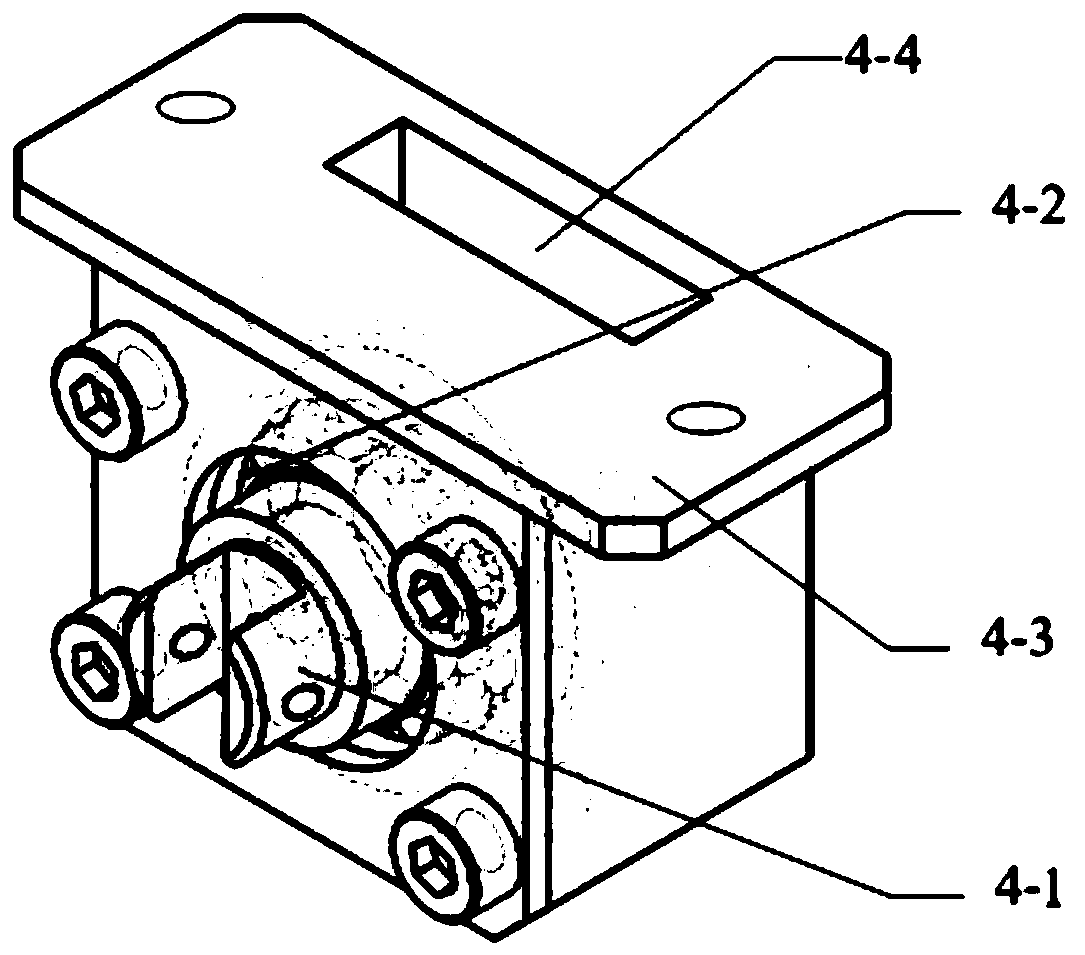

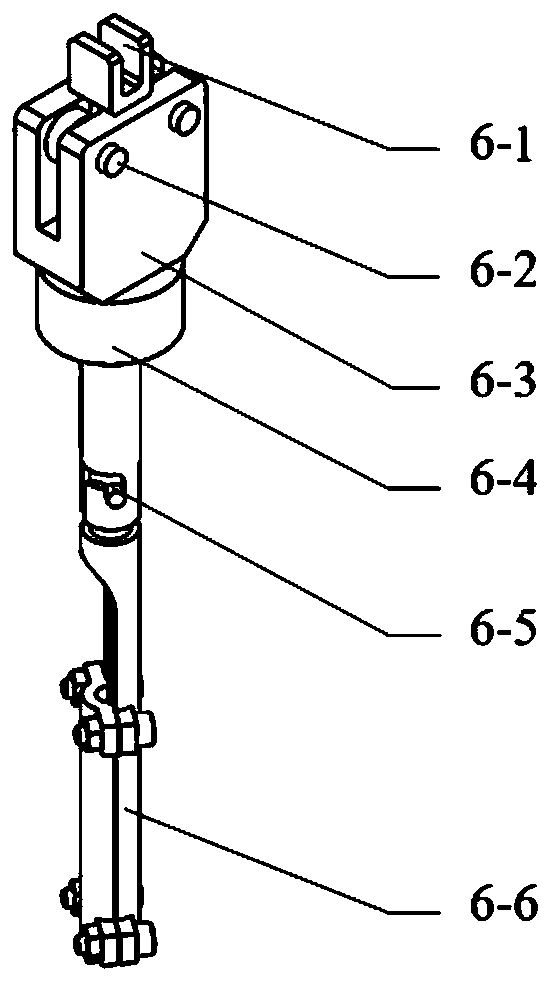

[0022] This embodiment provides a tethered UAV mooring cable pull force vector measurement mechanism, through which the measurement mechanism can measure and feed back the mooring cable pull force vector information in real time, so that the flight control system can effectively control the UAV.

[0023] The basic principle of the measurement mechanism is: the mooring cable is connected with the mooring UAV through the mooring cable pulling mechanism, firstly, the mooring cable pulling mechanism is set to ensure the distance between the mooring cable and the mooring cable pulling mechanism connection point. The tethered cable extension line always passes through the center of gravity of the UAV, and the direction pointed by the extension line is the direction of the traction force vector; on this basis, multiple sensors are arranged to measure the direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com