A kind of vanadium-titanium alloy gray cast iron cylinder liner and preparation method thereof

A gray cast iron and cylinder liner technology, applied in the field of vanadium-titanium alloy gray cast iron cylinder liner and its preparation, can solve the problems of low strength and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

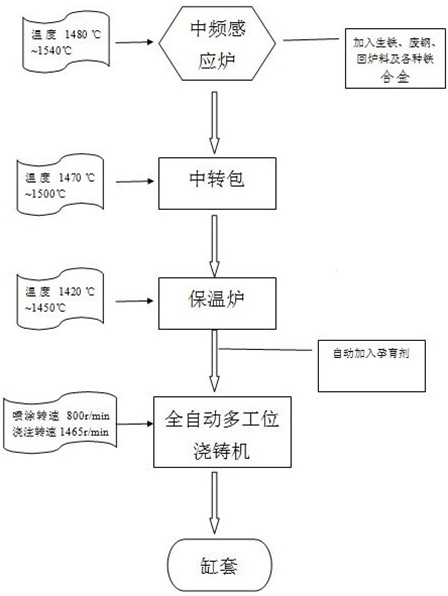

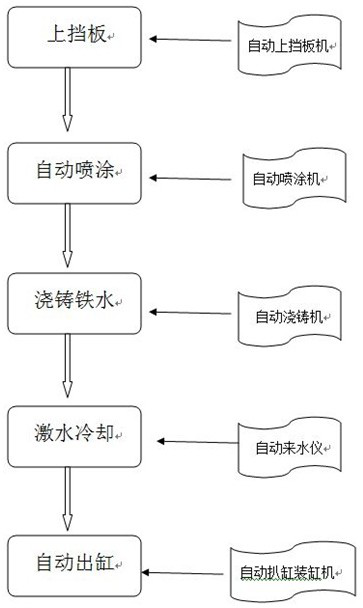

[0092] The present invention also provides a method for preparing an alloy gray cast iron cylinder liner, comprising the following steps:

[0093] 1) After the raw materials are smelted in an intermediate frequency induction furnace, they are then transferred to the holding furnace through a transfer bag, and after being kept for heat preservation, the molten iron after being released from the furnace is obtained;

[0094] 2) After the molten iron obtained in the above steps is fully automatic multi-station casting, it is demoulded to obtain the alloy gray cast iron cylinder liner.

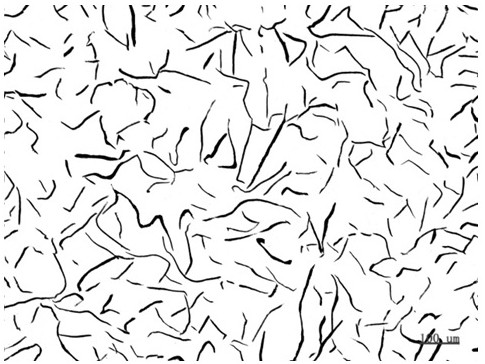

[0095] The present invention is to the parameters, microstructure and composition of the alloy gray cast iron cylinder liner in the above-mentioned preparation method, and the corresponding optimization principle, and the parameters, microstructure and composition corresponding to the aforementioned alloy gray cast iron cylinder liner, and the corresponding optimization principle. Correspondingly,...

Embodiment 1

[0134] The preparation method of vanadium-titanium sheath comprises the following steps:

[0135] Molten iron smelting: pig iron, scrap steel and returned materials, the ratio of pig iron, scrap steel and returned materials is 1.5:6.5:2, smelting in an electric furnace, adding alloys (silicon-manganese alloy, ferrophosphorus, ferro-vanadium, ferro-titanium, ferrochromium, iron sulfur and other ferroalloys and electrolytic copper, etc.), the temperature continues to rise to 1508 ° C until the furnace charge is completely dissolved, the furnace cover is covered and kept for 18 minutes, and fine-tuning is carried out to make its composition control see Table 3.

[0136] table 3

[0137] item C S Si P mn Cr Cu V+Ti Require 3.22 0.065 1.82 0.38 1.05 0.35 0.15 0.32

[0138] The smelted molten iron is treated with slag removal to ensure that there is no iron slag and other inclusions in the molten iron. The molten iron is transferred to the hol...

Embodiment 2

[0151] The preparation method of above-mentioned vanadium-titanium sleeve comprises the following steps:

[0152] Molten iron smelting: use pig iron, scrap steel and returned materials, the ratio of pig iron, scrap steel and returned materials can be controlled according to the cost, such as controlled at 2.5:5.5:2, smelting in an electric furnace, adding alloys (silicon-manganese alloy, Ferrophosphorus, ferrovanadium, ferrotitanium, ferrochromium, ferrosulfur and other ferroalloys and electrolytic copper, etc.), the temperature continues to rise to 1532 ° C, cover the furnace cover and let it stand for 21 minutes to keep warm for 21 minutes, and fine-tune the ingredients. See Table 5 for its composition.

[0153] table 5

[0154] item C S Si P mn Cr Cu V+Ti Require 3.34 0.084 1.88 0.41 0.72 0.35 0.17 0.36

[0155] The smelted molten iron is treated with slag removal to ensure that there is no iron slag and other inclusions in the molten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com