Automatic angle steel feeding, overturning, machining and discharging classification device

A turning device and automatic feeding technology, which is applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of low efficiency and unsuccessful turning, and achieve a high degree of automation, reduce labor costs, and high accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments, which are not intended to limit the scope of rights of the present invention.

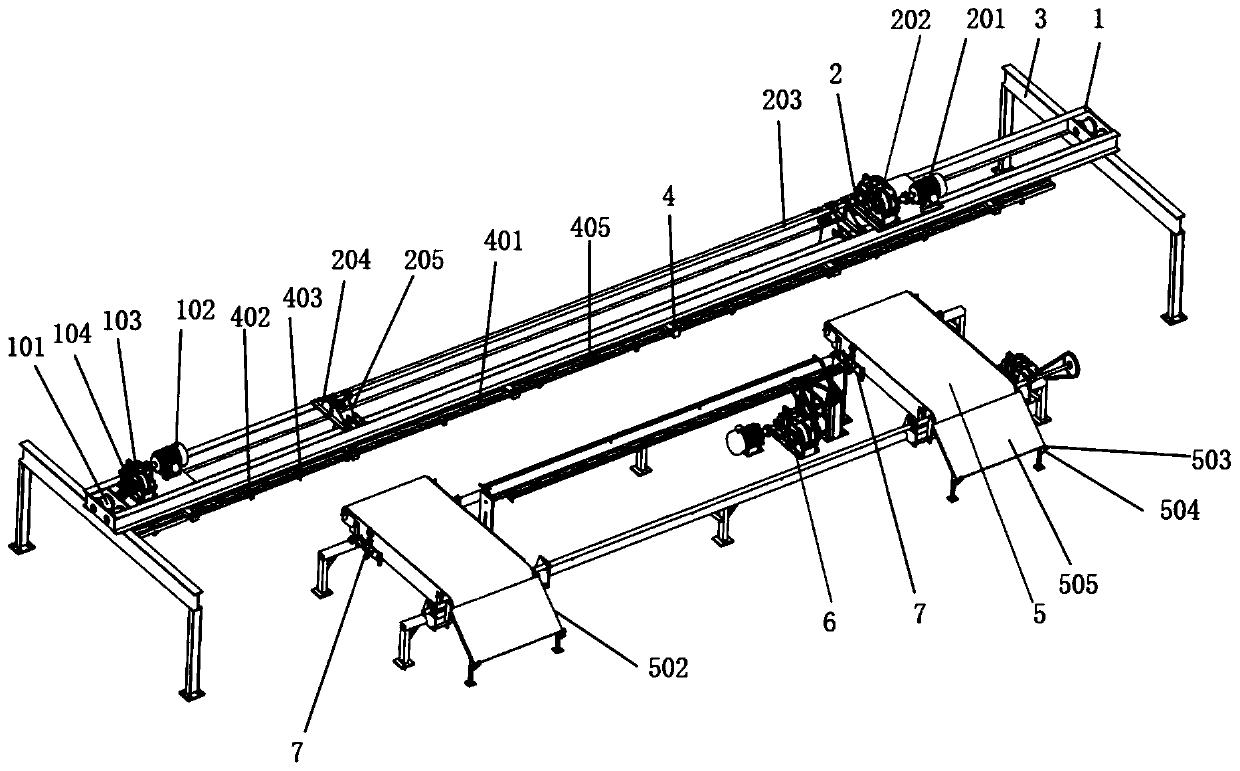

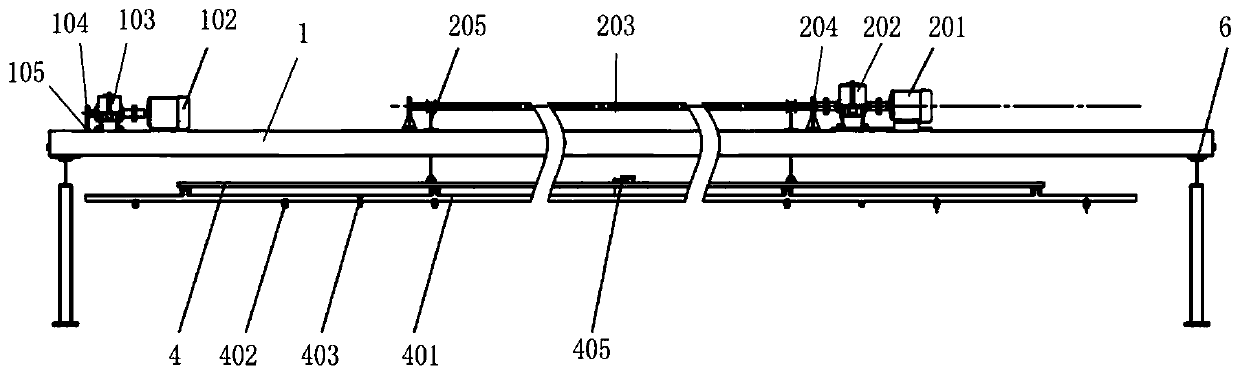

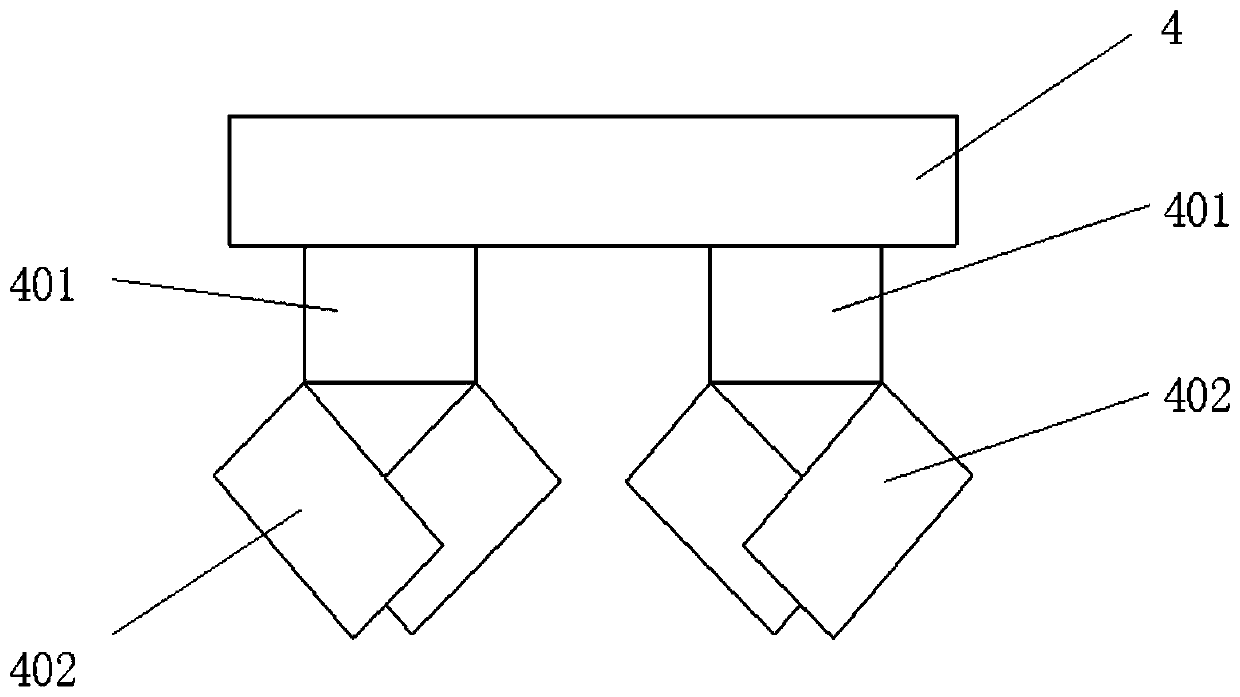

[0052] This specific embodiment provides an angle steel automatic feeding, turning, processing and unloading classification device, such as Figure 1 to Figure 9 As shown, it includes a feeding machine, an angle steel punching machine, a blanking path support 8, a V block transfer mechanism and a blanking classification mechanism.

[0053] Such as figure 1 As shown, the loading machine includes a loading carriage 1 , a winch 2 , a first turning mechanism 6 and a second turning mechanism 7 .

[0054] Such as figure 2 As shown, two ends of the bottom of the loading carriage 1 are respectively provided with two feeding guide wheels 101, and the feeding carriage 1 is movably connected to the feeding I-beam track 3 through the feeding guide wheels 101, and the feeding g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com