Self-adaptive follow-up traction mechanism for mooring cable of mooring unmanned aerial vehicle

A pulling mechanism and self-adaptive technology, which is applied in the field of pulling mechanism and tethered UAV traction mechanism, can solve problems that affect the service life of the UAV, damage related parts of the body, consume more energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below with reference to the accompanying drawings and examples.

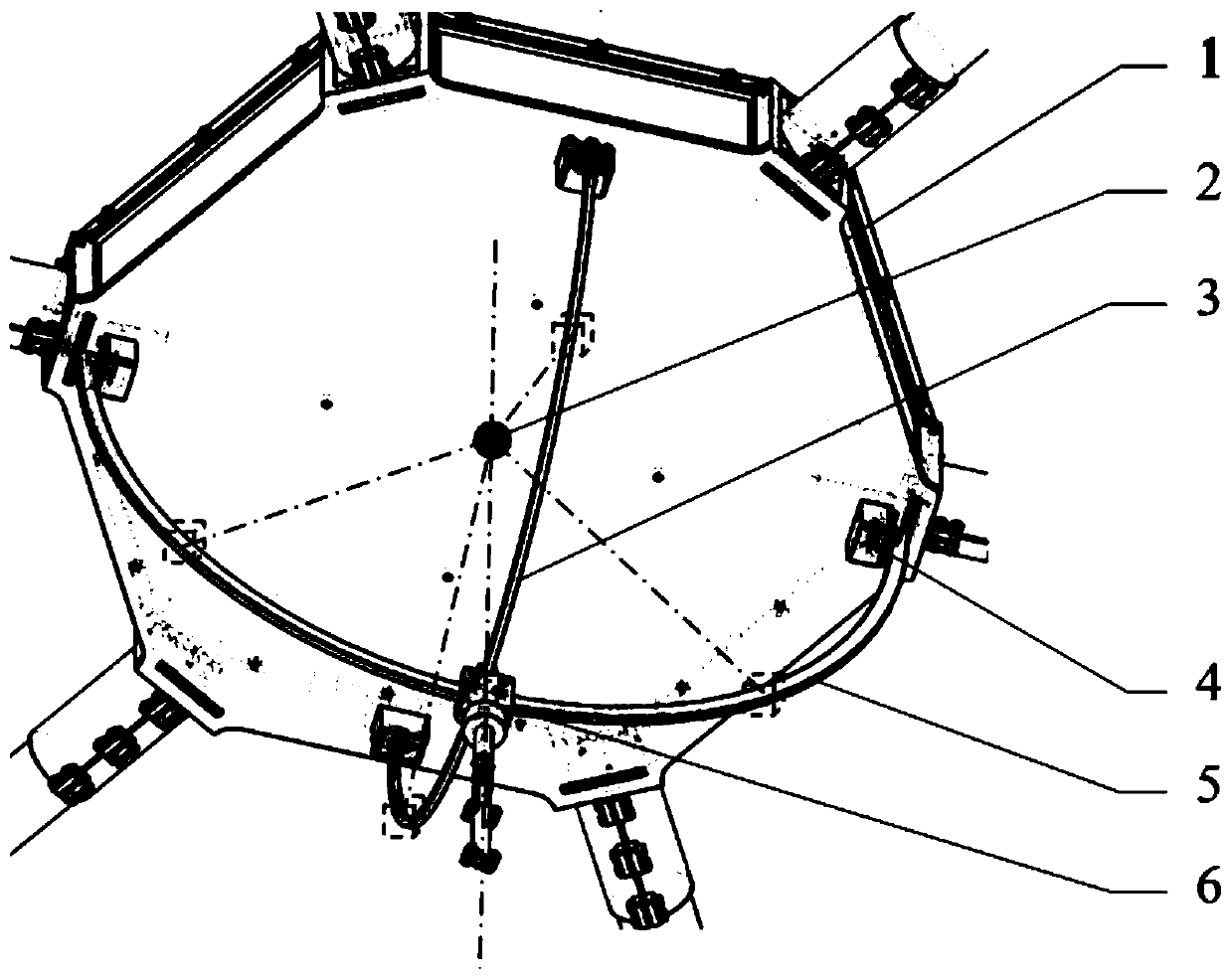

[0021] This embodiment provides an adaptive follow-up pulling mechanism for the mooring cable of a tethered UAV, which can automatically adjust the position of the connection point of the mooring cable according to the flight state of the tethering UAV, so that The extension line always passes through the center of gravity of the tethered drone, thereby eradicating the influence of eccentric moments.

[0022] The basic principle of the pulling mechanism is to change the fixed connection of the traditional mooring cable of the tethered UAV to an adaptive follow-up connection, so that the tethered cable extension line passing through the connection point always passes through the center of gravity of the UAV.

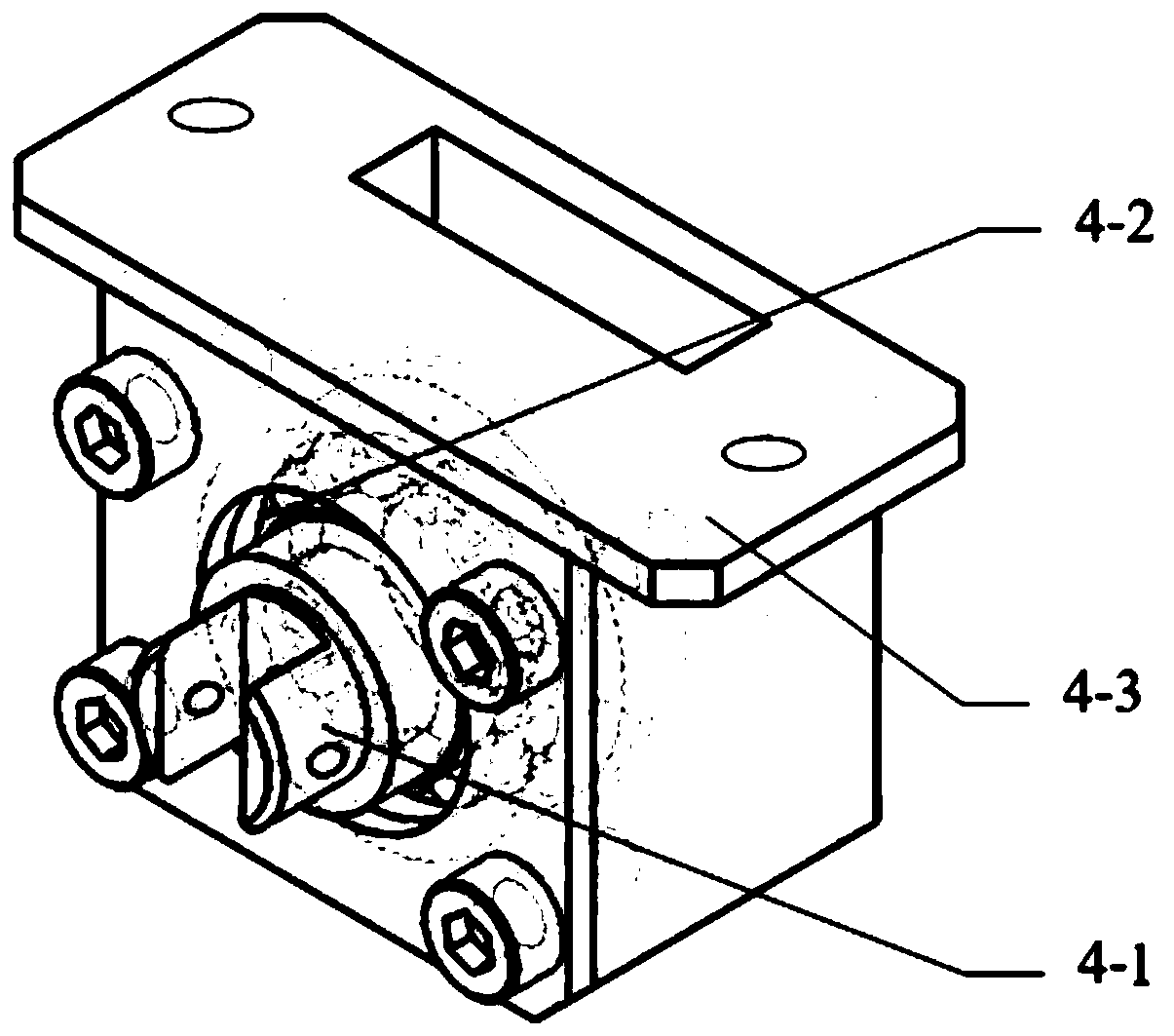

[0023] like figure 1 As shown, the mooring cable self-adaptive follow-up pulling mechanism includes: a guide pull ring 3, a load-bearing pull ring 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com