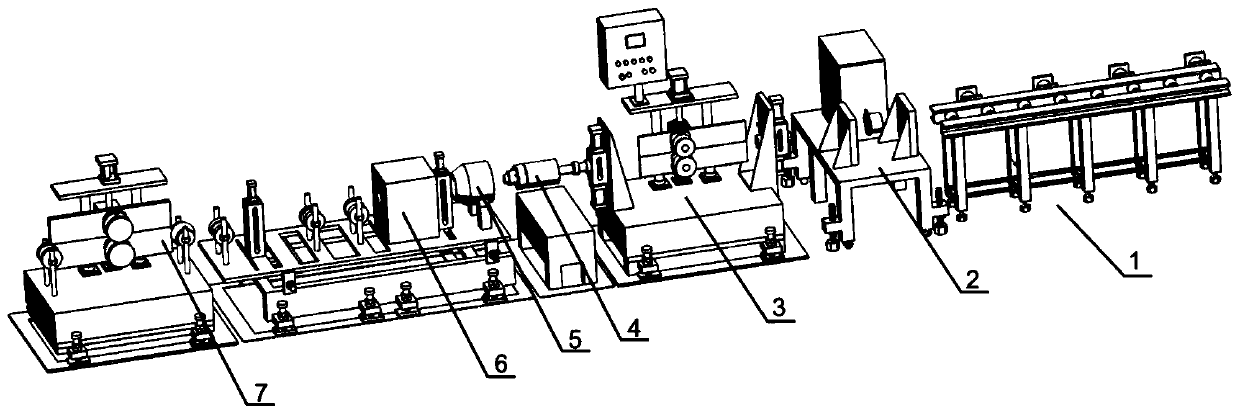

Oil-sucking rod continuous full cladding production line and cladding method thereof

A sucker rod and production line technology, applied in the direction of coating, etc., can solve the problems of different cross-section sizes, imprecise coating, scratches on sucker rods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0155] Cover one sucker rod with a total length of 8.5m, the diameter of the sucker rod is φ19.05mm, and the width of the wrench square is φ25.40mm;

[0156] Before work, 3 steps are required, namely:

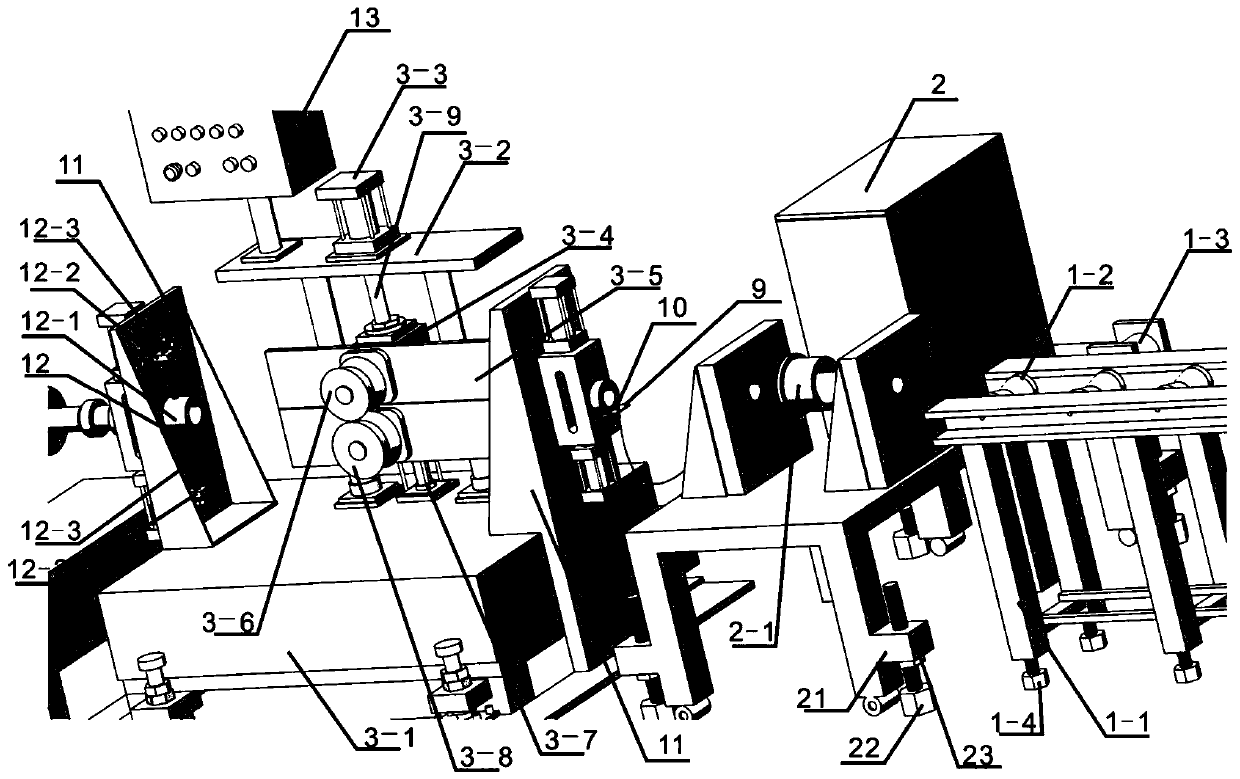

[0157] 1. Adjust the height of the production line according to the diameter of the sucker rod 24 to be coated, so that all the tooling used to support the sucker rod 24 equipment is on a straight line, specifically:

[0158] ①The sucker rod 24 is placed in the concave part of the roller I1-2, and then the sucker rod 24 is pushed to enter the induction coil 2-1 of the intermediate frequency heating device 2, and the intermediate frequency heating is further adjusted by twisting the screw nut II22 and the bolt III23 The height of the device 2 further enables the sucker rod 24 to pass through the center of the induction coil 2-1;

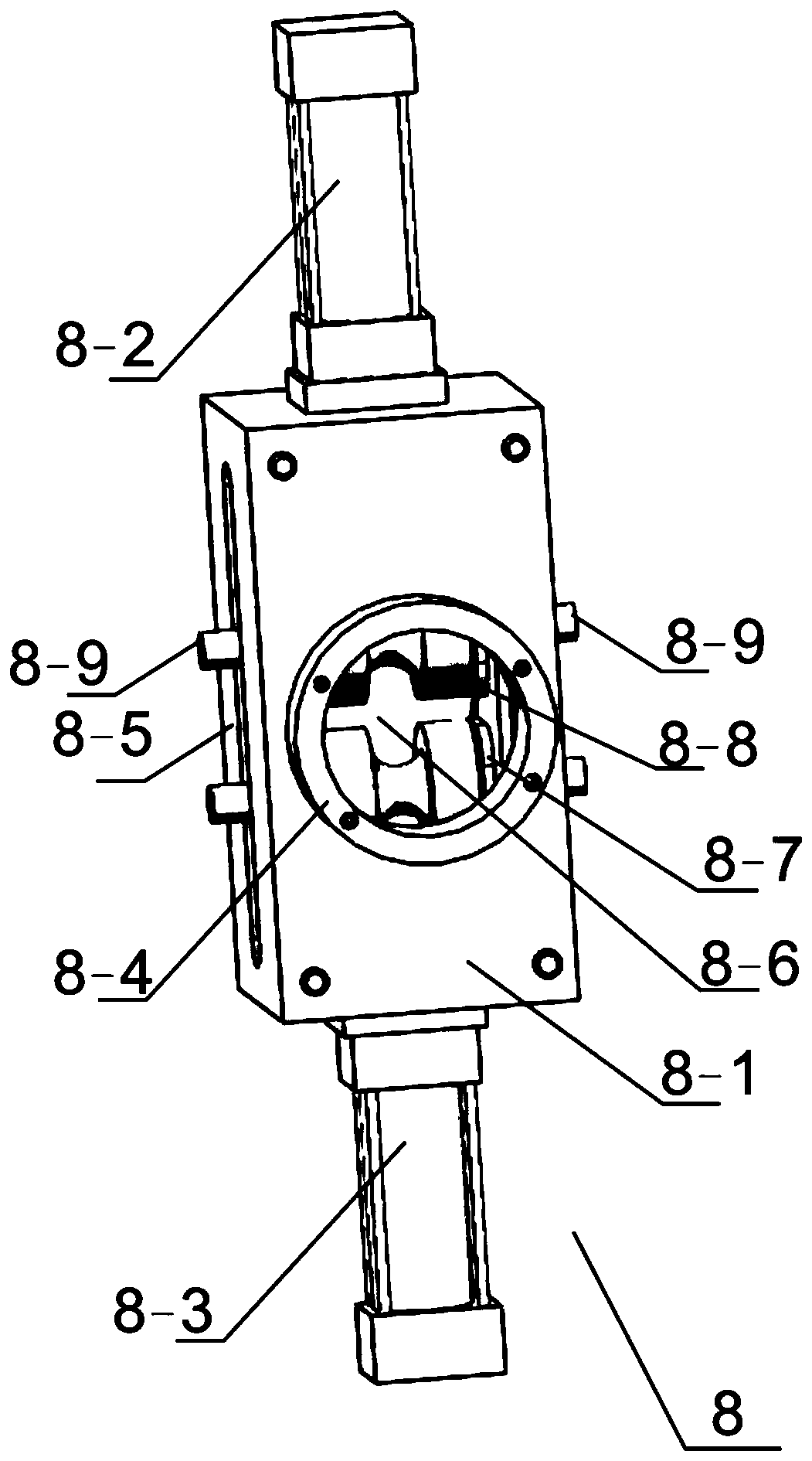

[0159] ②The sucker rod penetrates into the positioning cavity 8-6 from the inlet port 8-4 on the positioning device 8, and then the upper nitrogen cy...

Embodiment 2

[0178] Cover 5 single sucker rods with a total length of 8.5m, the diameter of the sucker rod is 19.05mm, the total length is 8.5m, and the width of the spanner is φ25.40mm; The buckle 24-1 is threadedly connected with the female buckle 24-2, so that a plurality of the sucker rods 24 are connected into a line; most of the parameters set during the coating of the embodiment 1 are continued, and since one sucker rod 24 has two joints, and 5 joints are covered in series when covering, so the terminal controller is set to cover the small diameter of the sucker rod with the normal amount of covering material when the first second section of the first sucker rod is detected part, when detecting the second second section of the first sucker rod, increase the amount of coating material, and when detecting the first second section of the second sucker rod, use the normal amount of coating material to cover the pumping rod. The small diameter part of the oil rod, and so on..., the secon...

Embodiment 3

[0189] After being coated with different coating materials, the inspection is carried out. The inspection results are as follows:

[0190]

[0191]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com