Processing and forming method of bridge-cut-off aluminum alloy section bar

An aluminum alloy profile, processing and forming technology, applied in the field of aluminum alloy profile, can solve the problems of reducing die-casting forming efficiency, sheet material cracking, wasting production time, etc., and achieve the effects of improving efficiency and quality, ensuring cleanliness, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

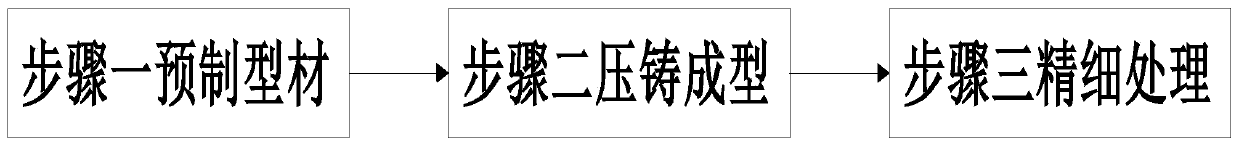

[0029] like Figure 1 to Figure 8 As shown, a method for processing and forming a broken bridge aluminum alloy profile mainly includes the following steps:

[0030] Step 1, prefabricated profile: cutting the aluminum alloy plate according to the regulations to obtain the blank aluminum alloy plate;

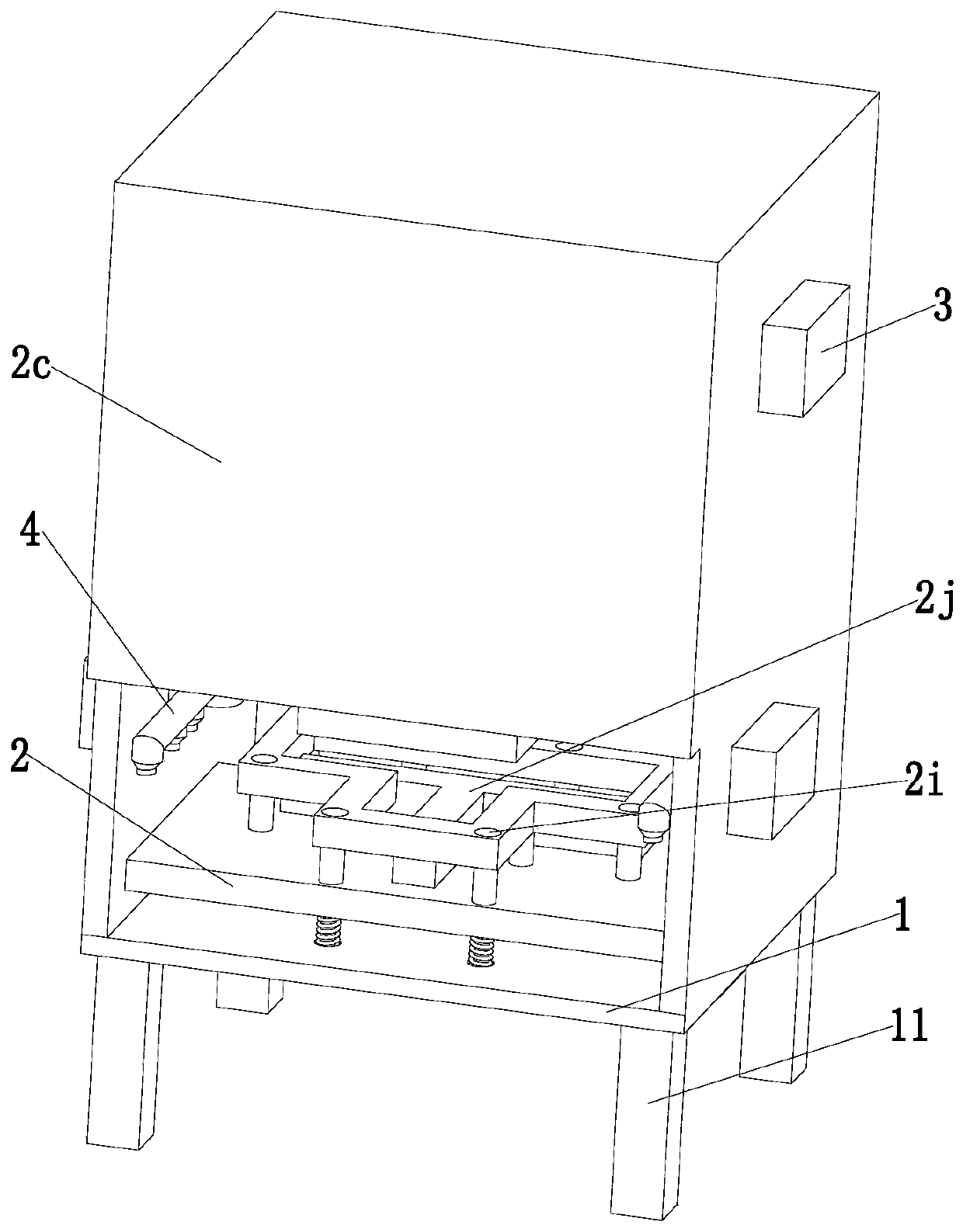

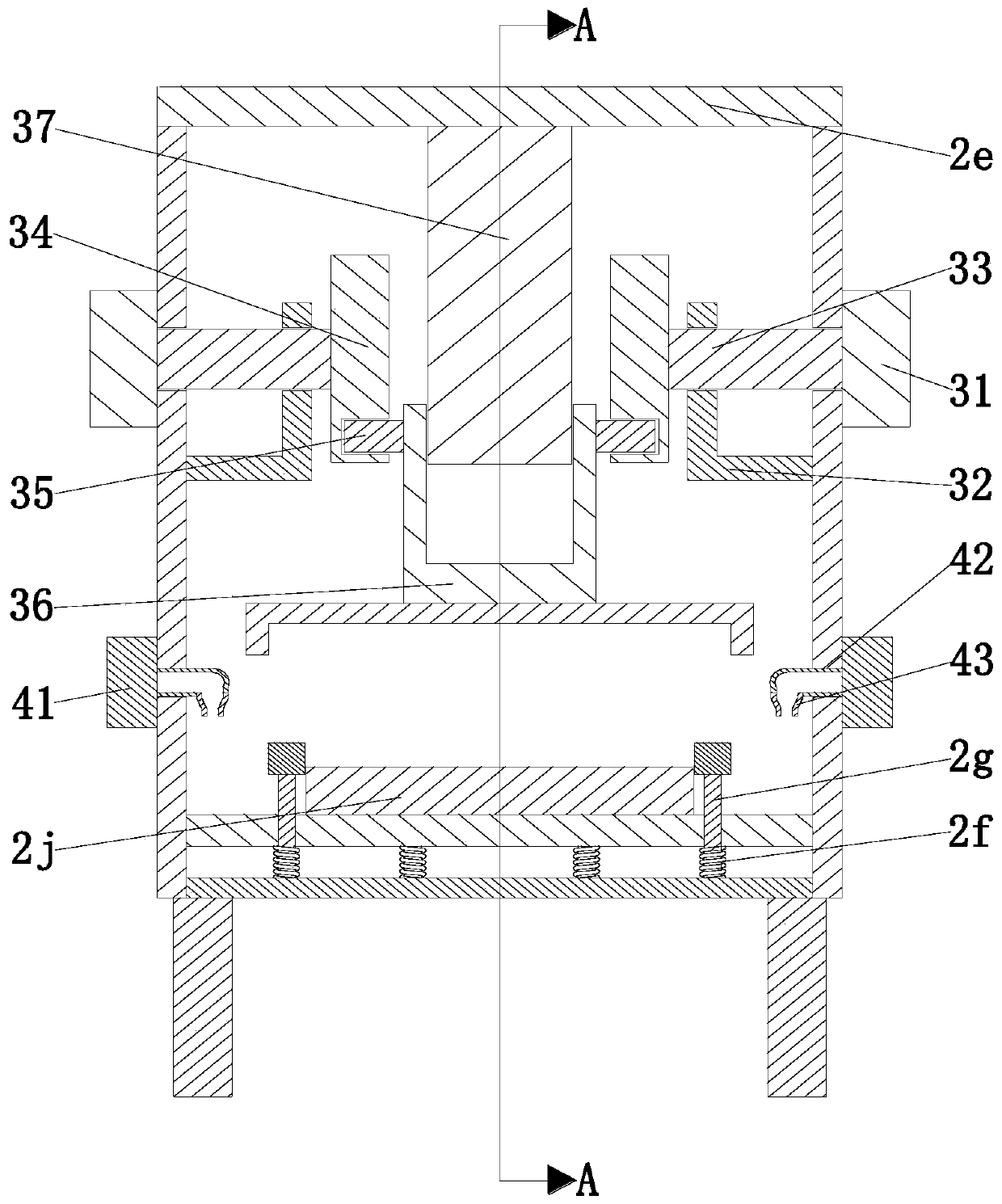

[0031] Step 2, die-casting forming: placing the blank aluminum alloy plate obtained in step 1 into the aluminum alloy die-casting forming equipment for die-casting forming operation, and obtaining the broken bridge aluminum alloy profile;

[0032] Step 3, fine treatment: perform fine grinding treatment on the broken bridge aluminum alloy profiles obtained in step 2, to obtain finished bridge broken aluminum alloy profiles.

[0033] The aluminum alloy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com