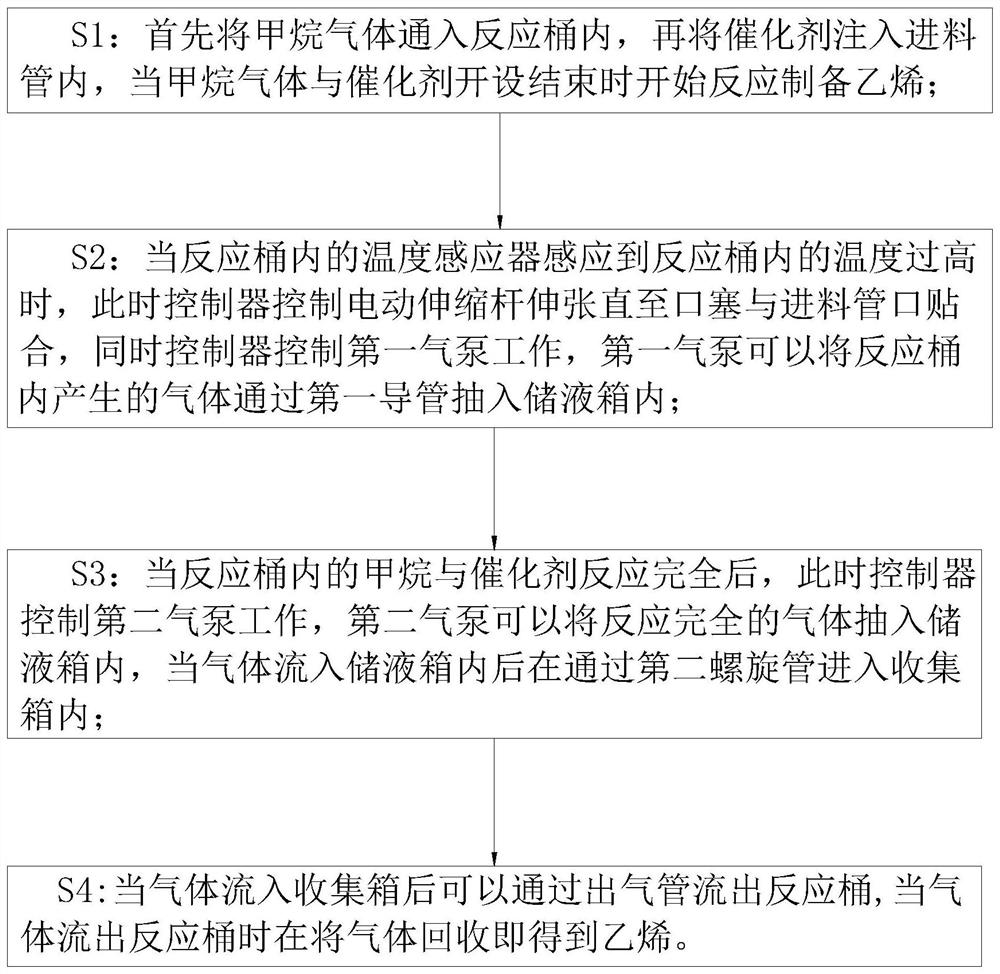

A methane oxidative coupling reaction device and its process for producing ethylene

A technology of oxidative coupling and reaction devices, applied in organic chemistry, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as catalyst sintering, reaction device damage, catalyst layer thickening, etc., to ensure reaction speed and improve The effect of vibration duration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

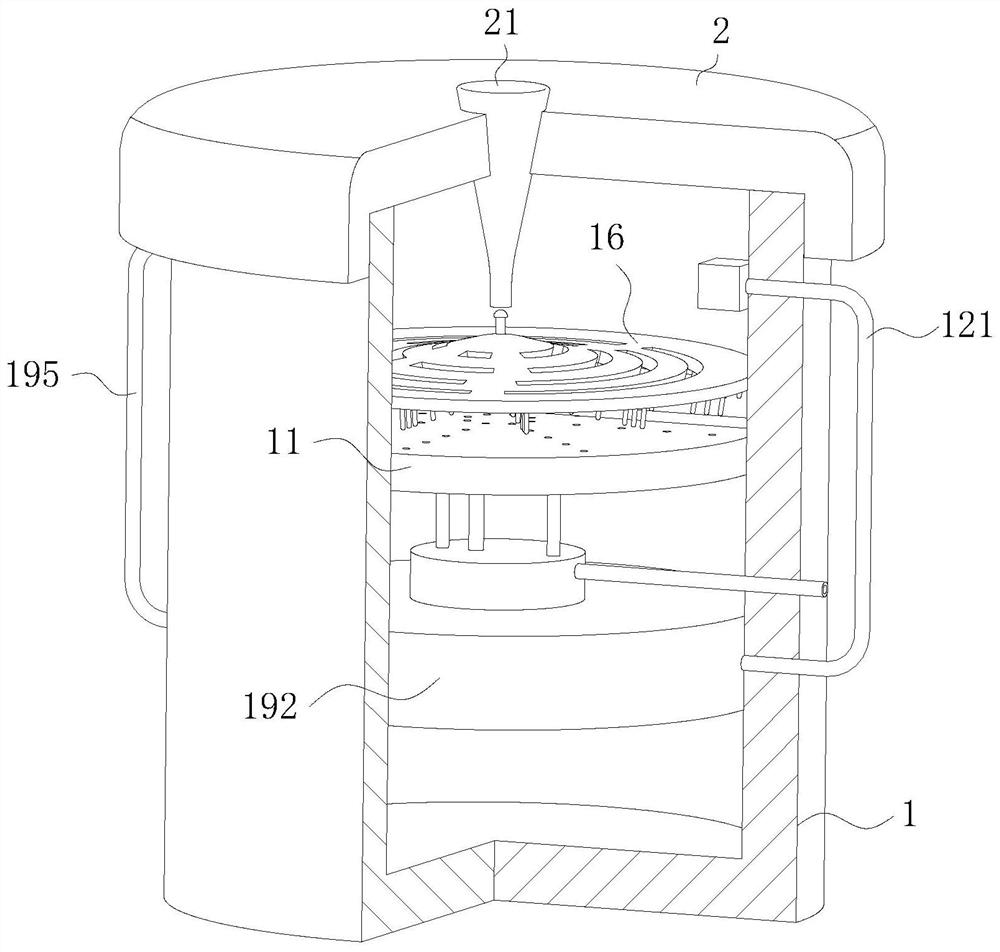

[0035] As an embodiment of the present invention, uniformly arranged delivery pipes 198 are fixedly connected to the inner wall of the vibration layer 197 , and the delivery pipes 198 all extend below the reaction layer 11 ; a collection box is fixedly installed above the liquid storage tank 192 199, the conveying pipes 198 all extend into the collection box 199; the inner surface of the reaction barrel 1 is fixedly connected with a second air pump 111 on the inner surface of the right side of the reaction barrel 1; the right side of the second air pump 111 is fixedly connected with a second conduit 121, and the second conduit 121 extends into the liquid storage tank 192; the liquid storage tank 192 is fixedly connected with a second spiral tube 131, and the second spiral tube 131 communicates with the second conduit 121; the second spiral tube The other end of 131 extends to the top of the collection box 199; the inner wall of the right side of the collection box 199 is fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com