Mechanical interlocking type pressure ventilation pipe automatic drainage device

A technology of automatic water discharge and mechanical interlocking, which is applied in the direction of valve operation/release device, valve device, mechanical equipment, etc. It can solve the problems of water accumulation in the air pressure pipe and failure to discharge water in time, to simplify the circuit and eliminate the loss of pressure. , the effect of improving stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

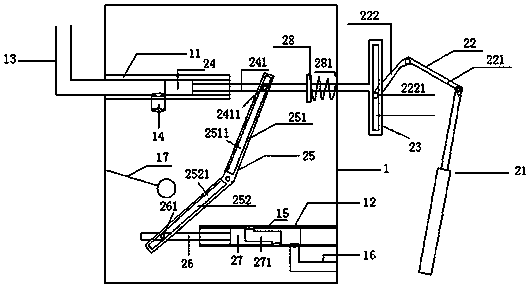

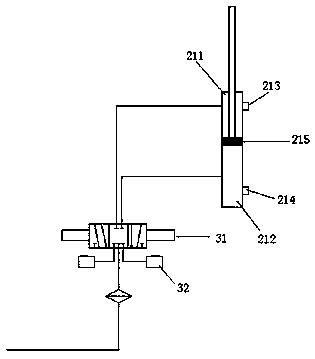

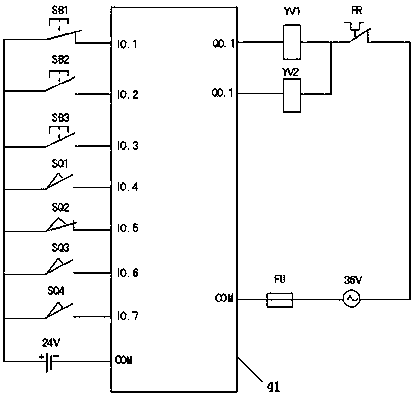

[0020] Such as figure 1 As shown, the mechanical interlocking type pressure air pipe automatic water discharge device of the present invention includes a water storage mechanism 1, a drainage piston mechanism 2, a pneumatic control mechanism 3 and a cylinder electric control mechanism 4;

[0021] The water storage mechanism 1 is a cubic container. On the side wall of the water storage mechanism 1 near the top and bottom, a water inlet pipe sleeve 11 and a water discharge pipe sleeve 12 extending inwardly are arranged, and a water inlet pipe is arranged in the water inlet pipe sleeve 11. 13. The water inlet pipe 13 enters the water inlet pipe sleeve 11 through the side wall from the outside of the water storage mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com