Flow guiding device for cooling turbine inlet working substance

A technology of diversion device and working medium flow, which is applied in jet propulsion device, air inlet of turbine/propulsion device, gas turbine device, etc. Machine efficiency, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

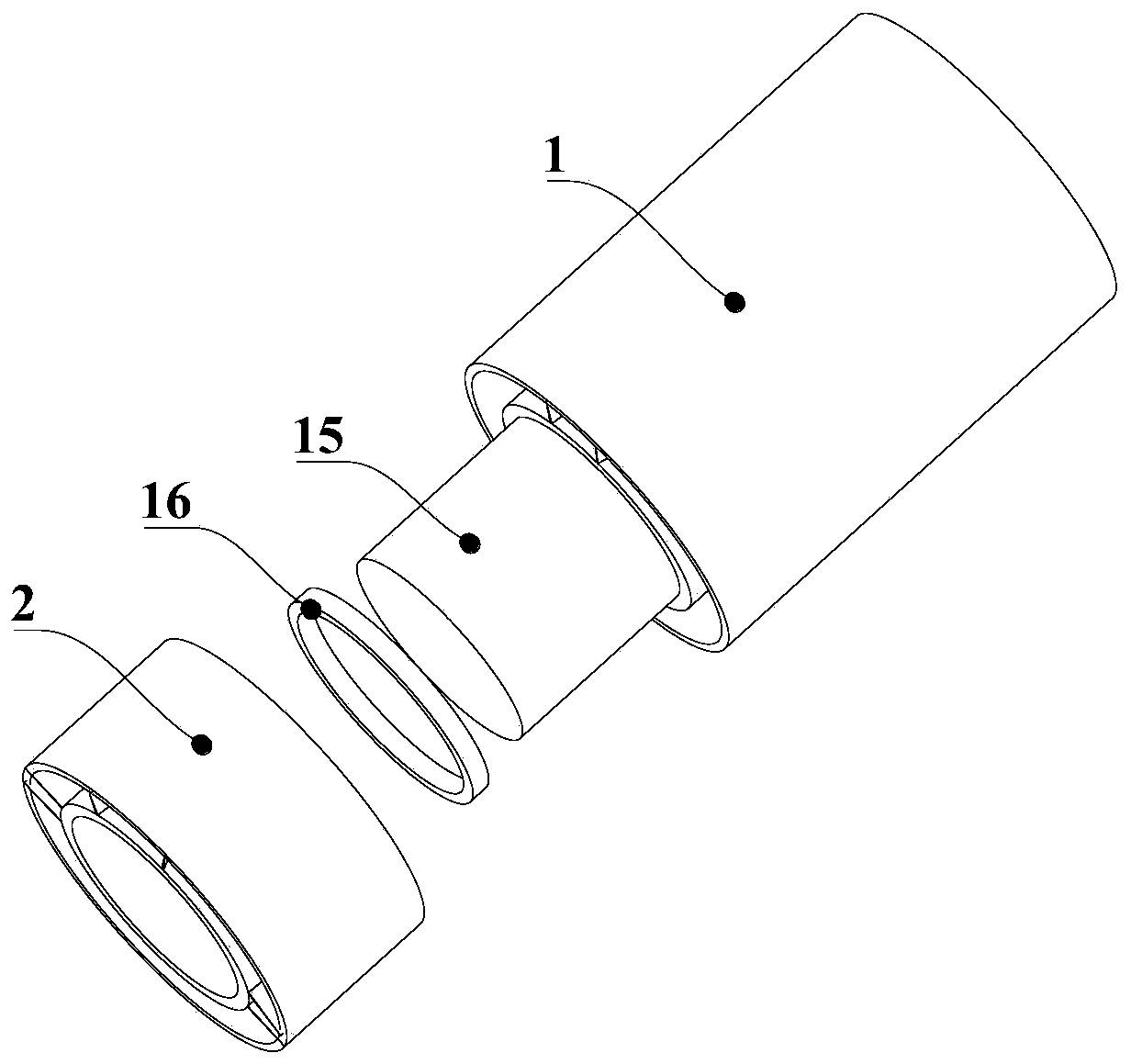

[0026] This embodiment provides a flow guide device for cooling the inlet working fluid of the turbine, which is used to guide the flue gas working fluid discharged from the outlet of the combustion chamber in the gas turbine to the turbine. Refer to figure 1 and figure 2 , including a body 1 axially limited between the combustion chamber and the turbine, the body 1 has an annular cavity 11 matched with the outlet of the combustion chamber, and the annular cavity 11 is provided with a Leading to the working medium flow channel 12 of the turbine, the working medium flow channel 12 at least includes a tapered section 121 where the flow guide plates 13 on both sides gradually approach, and the flow guide plates 13 on both s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com