Full damping channel valid MR damper

A magnetorheological damper, full damping technology, applied in building components, anti-vibration and other directions, can solve the problems of the maximum output loss of the damper and the reduction of the width of the coil groove, and achieve the effect of improving the use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

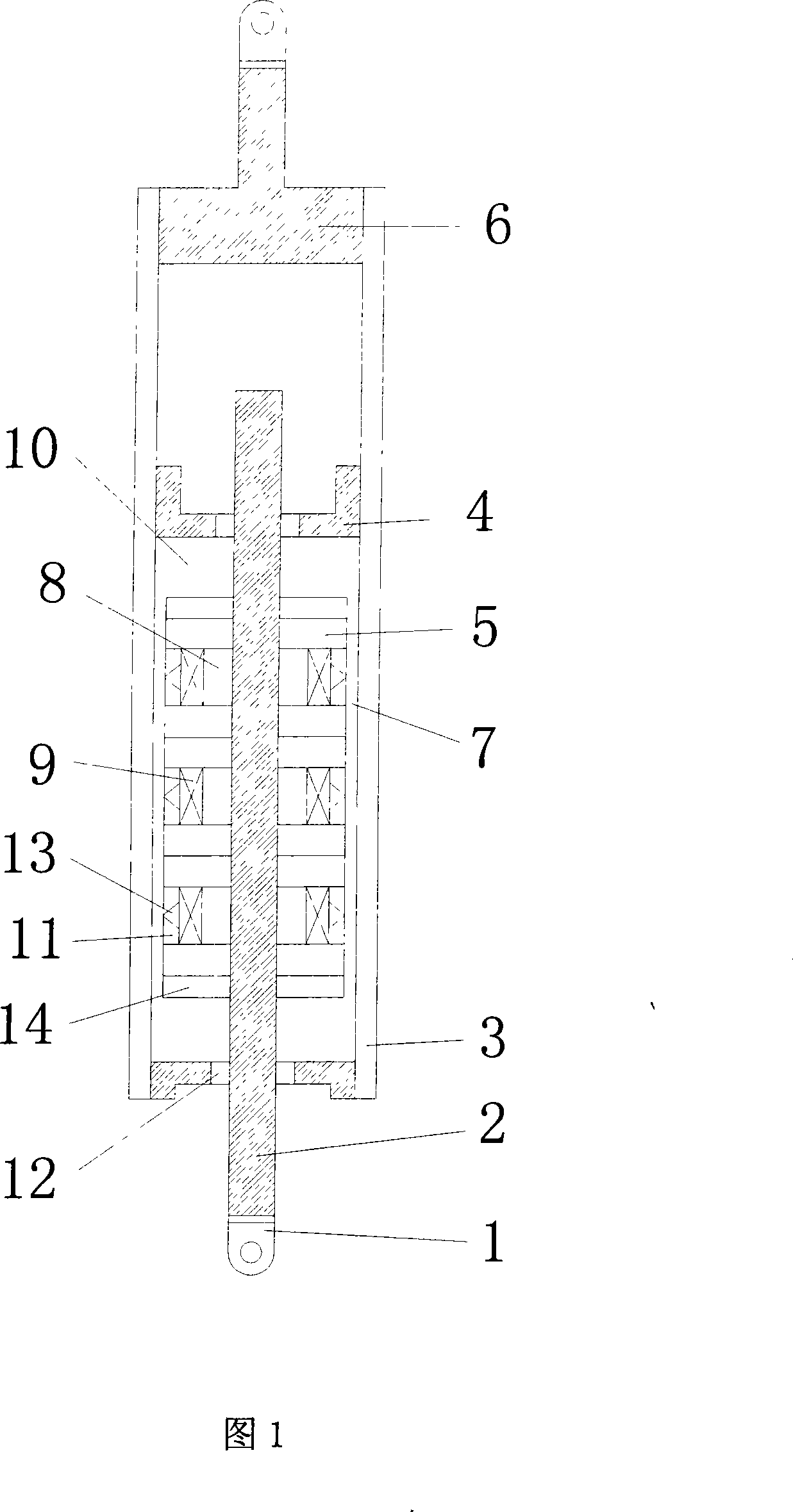

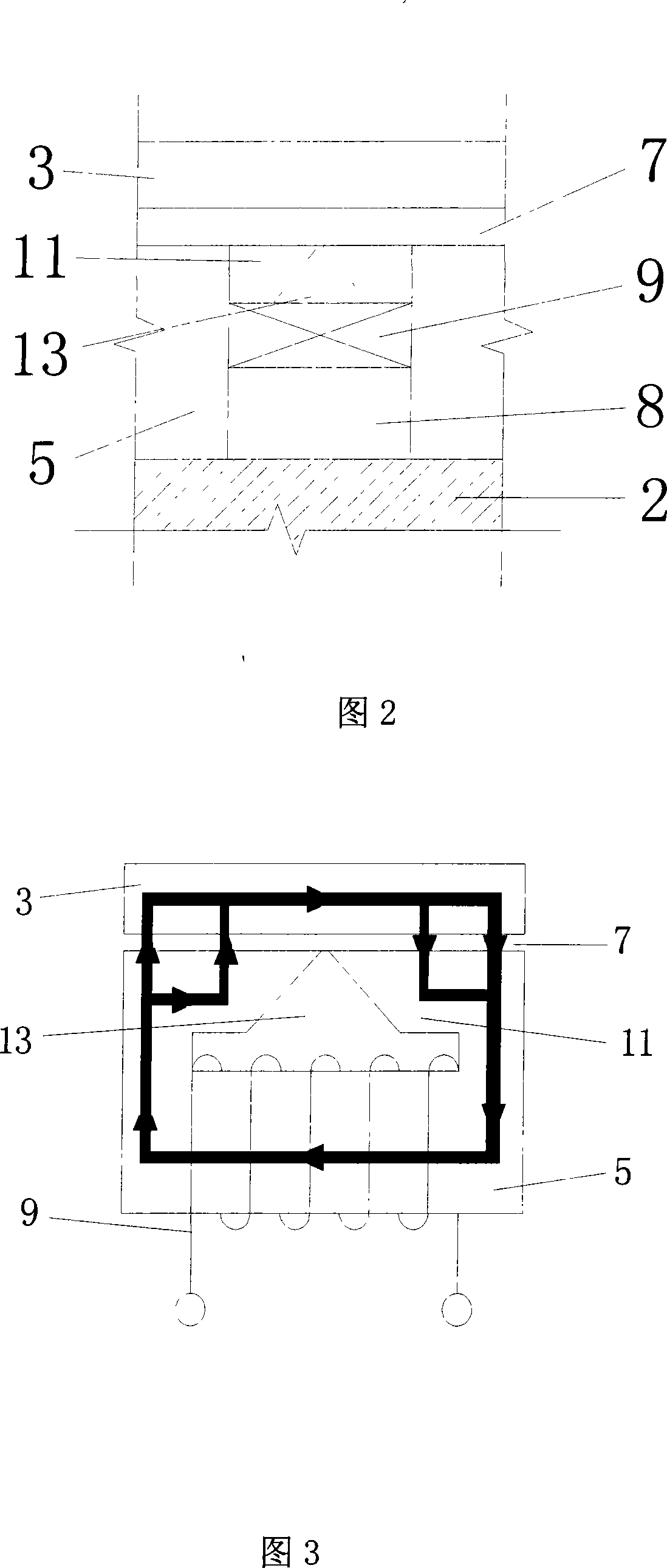

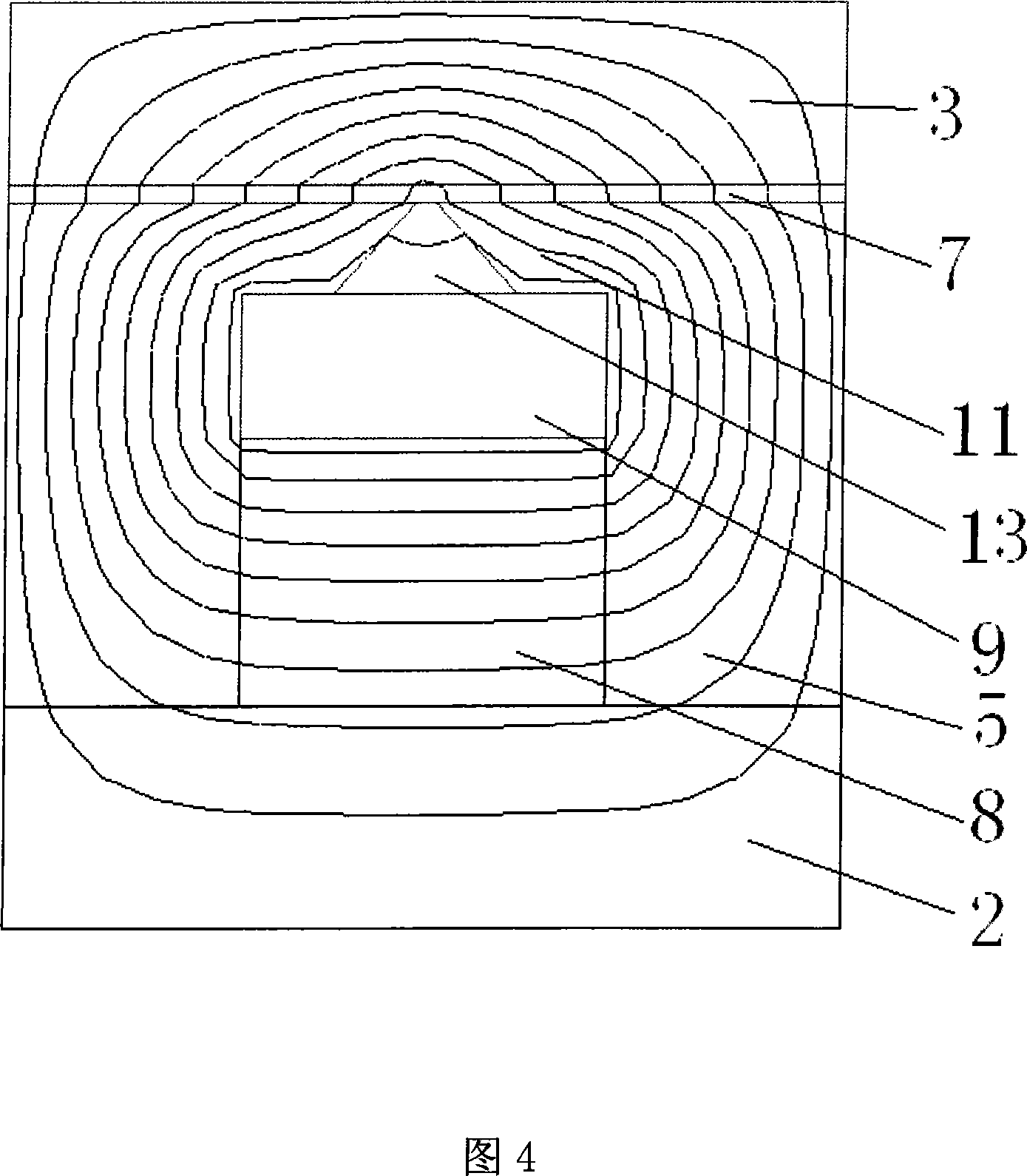

[0016] As shown in Fig. 1 and Fig. 2, the magneto-rheological damper with effective full damping channel includes a cylinder 3, a piston rod 2, a magnetic core sleeve 8, a piston disc 5, a damping channel 7, and an end cover 4 , magnetorheological fluid 10, excitation coil 9, stainless steel resistance disk 14, sealing ring 12, magnetization collar 11, magnetism resistance collar 13, bottom cover 6 and earring 1. There are multiple piston disks 5, and the piston disks 5 in the middle position are arranged in pairs. The piston disks 5 and magnetic core sleeves 8 of each segment are sequentially set on the piston rod 2, and the magnetic core sleeve 8 is wound on the outside for excitation. Coil 9, a pair of magnetizing collars 11 are placed between the excitation coil 9 and the damping channel 7, and a wedge-shaped magnetic-resistant collar 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com