Grouting method for soil reinforcing through microbe induced mineralization by introducing of urease inhibitors

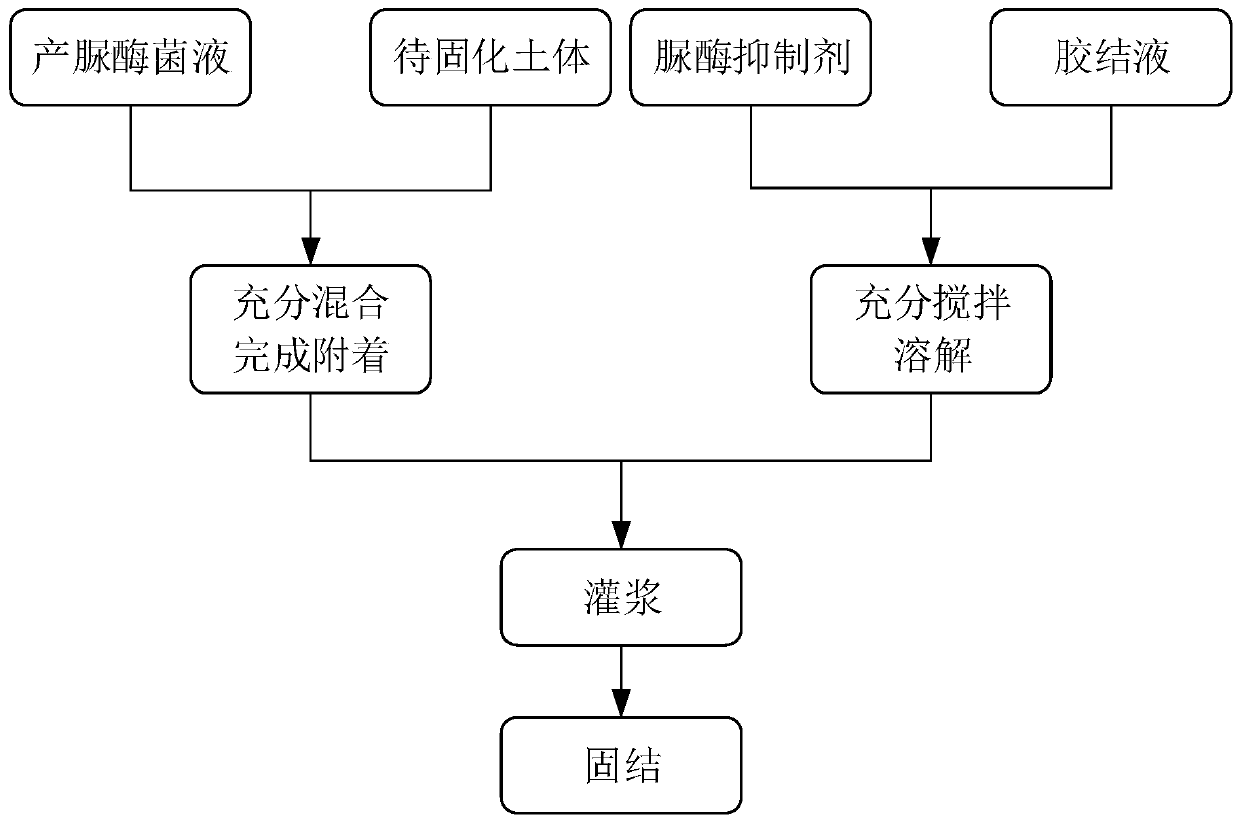

A urease inhibitor and soil reinforcement technology, which is applied in the field of new foundation treatment by using microorganisms to induce mineralization to improve soil strength, can solve the problems of calcium carbonate deposition blockage, uneven curing effect, and increase the difficulty and cost of construction, etc. Achieve the effects of delaying deposition, reducing local deposition rate, and improving curing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0039] (1) Weigh 20g of yeast extract, 10g of NH4Cl, 10mg of MnSO4·H2O and 24mg of NiCl·6H2O, dissolve in 1000ml of deionized water, configure the required liquid medium, and adjust the pH to 8.5 with 1M NaOH solution. Sterilize the liquid medium at a high temperature of 121°C for 45 minutes, return the sterilized medium to room temperature, inoculate the Bacillus pasteurianus into the medium, and culture it with shaking at a temperature of 30°C at a frequency of 150r / min, culture time 24h.

[0040] (2) The sample preparation mold adopts a pvc pipe with an inner diameter of 38mm and a height of 100mm, and the sand soil adopts Xiamen ISO standard sand, with an average particle size of D 50 = 0.72 mm. The height of the sand filling is about 80mm, and permeable stones are laid at both ends of the sand column. The initial porosity of the sample is about 0.38 measured by the drainage volume. Water is injected into the sand column and the excess air is saturated with negative pres...

example 2

[0044] The preparation method of this example is the same as that of Example 1, except that the dosage of additive NBPT is increased, and the content of NBPT used accounts for 0.1% of the total amount of urea in the cementing liquid.

[0045] The test results show that after adding 0.1% of the additive NBPT, while simplifying the grouting process, the curing strength can reach 2.71MPa, and the grouting opening will not be quickly blocked in the early stage of grouting, and the overall curing effect can be more uniform.

example 3

[0047] The preparation method of this example is the same as that of Example 1, except that the dosage of additive NBPT is increased, and the content of NBPT used accounts for 0.5% of the total amount of urea in the cementing liquid.

[0048] The test results show that after adding 0.5% of the additive NBPT, while simplifying the grouting process, the curing strength can reach 1.45MPa, and the grouting opening will not be quickly blocked in the early stage of grouting, and the overall curing effect can be more uniform.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com